Production process for denim sewage treatment and pretreatment

A sewage treatment and production process technology, applied in the field of textile technology, can solve problems such as debris clogging, achieve the effects of reducing sludge volume, reducing height, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

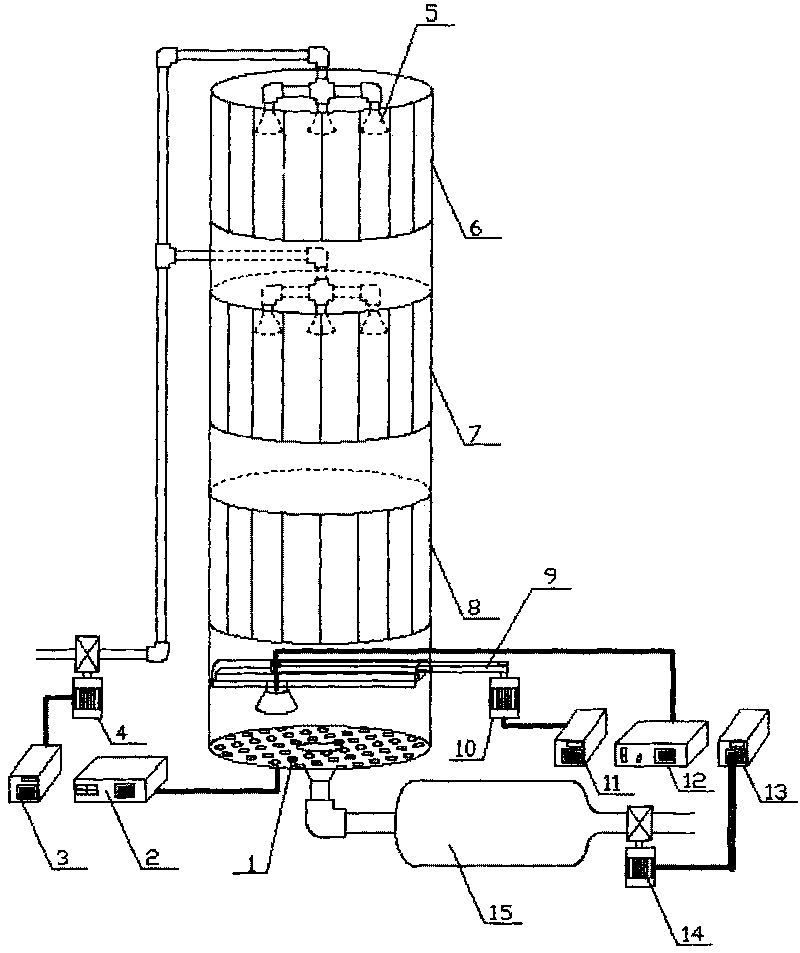

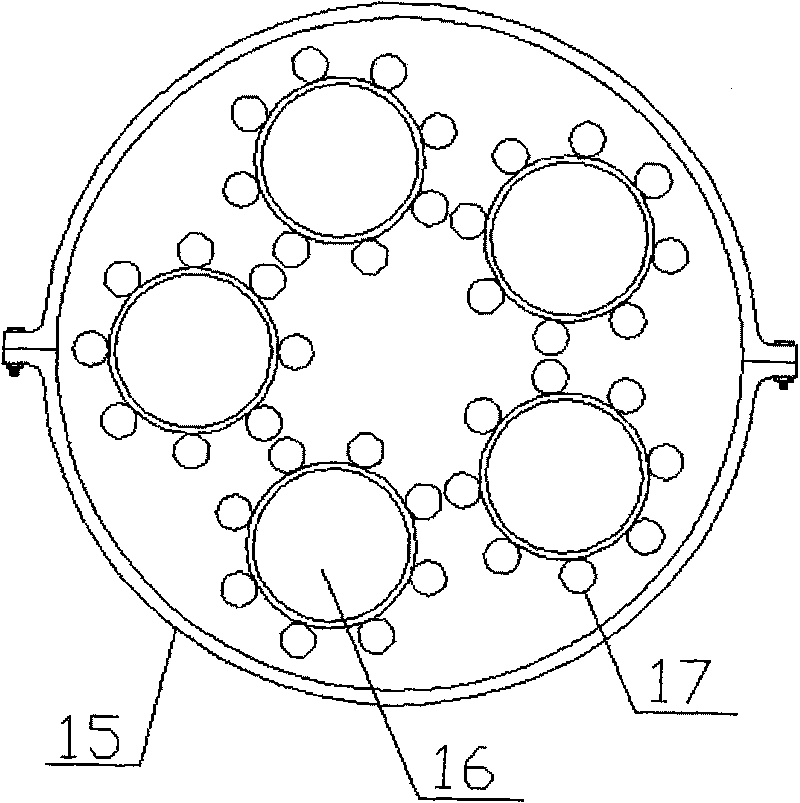

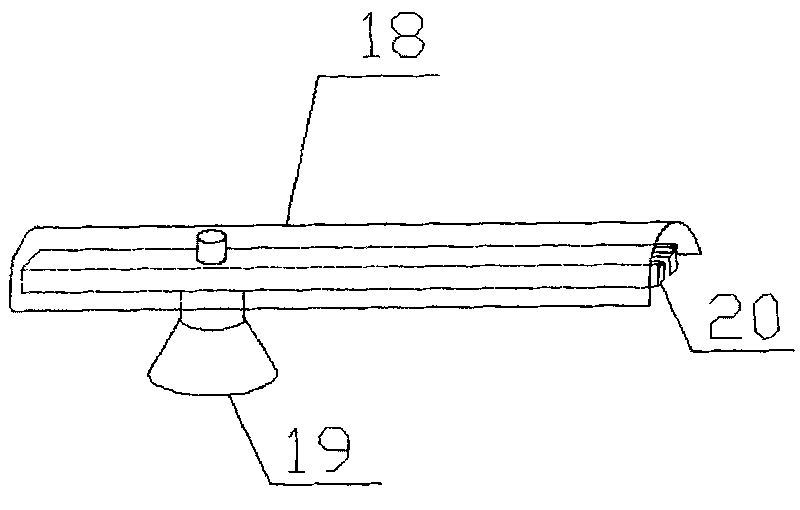

[0013] see Figure 1-3 , the specific embodiment adopts the following production process: 1. The waste water pretreated by physical precipitation etc. is first passed into the tower type biological filter for treatment; 2. The sewage is subjected to a laser scanning treatment; 3. The sewage is subjected to an ultrasonic treatment; 4. To irradiate the sewage once with ultraviolet rays. The above four processes are organically combined into one procedure, and the present invention is completed to control the organic pollutants, chroma, sulfide, alkalinity, etc. in the denim sewage.

[0014]The waste water that has been pretreated by physical precipitation in step 1 is first passed into the tower biofilter for treatment: the waste water has been pretreated to remove fine suspended matter such as cloth wool, thread ends, and fiber scraps, and the waste water mainly contains organic pollutants. , sulfide and other pollutants. Use a sewage pump 4 controlled by a frequency converte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com