Modified bamboo fiber composite material and preparation method thereof

A composite material and bamboo fiber technology, applied in the field of modified bamboo fiber composite material and its preparation, can solve the problems of low bonding strength of plant fiber and plastic interface, poor mechanical properties of composite materials, low tensile strength, low bending strength and the like , to achieve the effect of enhanced bonding force, increased flexural strength, and increased flexural modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Raw materials: o-phthalic unsaturated polyester resin (UPE resin) and initiator methyl ethyl ketone peroxide MEKP-94 were purchased from AOC Company (Collierville, TN, USA); bamboo fiber was provided by the Bamboo Engineering Research Center of Zhejiang Forestry University (the bamboo fiber Prepared by mechanical rolling method); modifier 1,6-hexamethylene diisocyanate was purchased from Sigma-Aldrich Company (Milwaukee, WI, USA), anhydrous ethyl acetate was purchased from EMD Chemicals Incorporated (Gibbstown, NJ, USA), 2-Hydroxyethyl acrylate was purchased from TCI America (Portland, OR, USA).

[0020] Bamboo fiber composite material:

[0021] Raw materials: unsaturated polyester is o-phthalic unsaturated polyester resin (its main components include ethylene glycol, propylene glycol, maleic anhydride, phthalic anhydride and styrene, etc.);

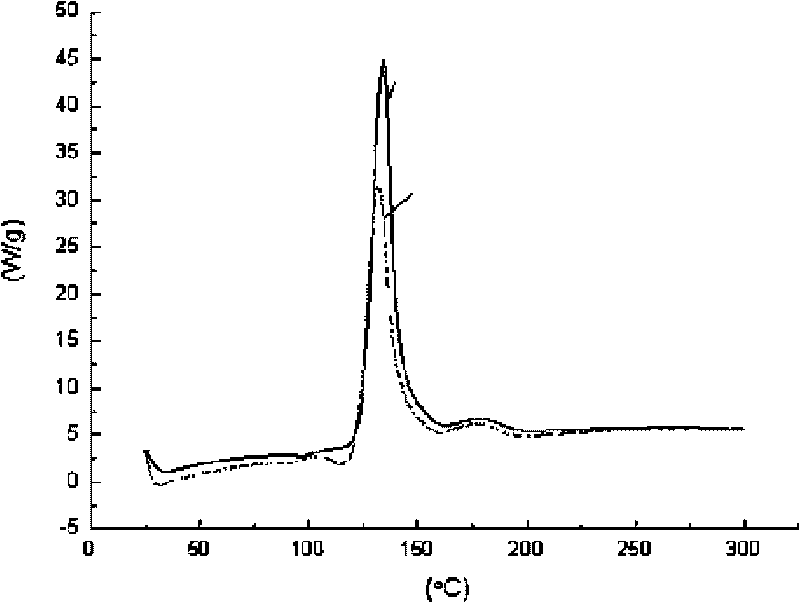

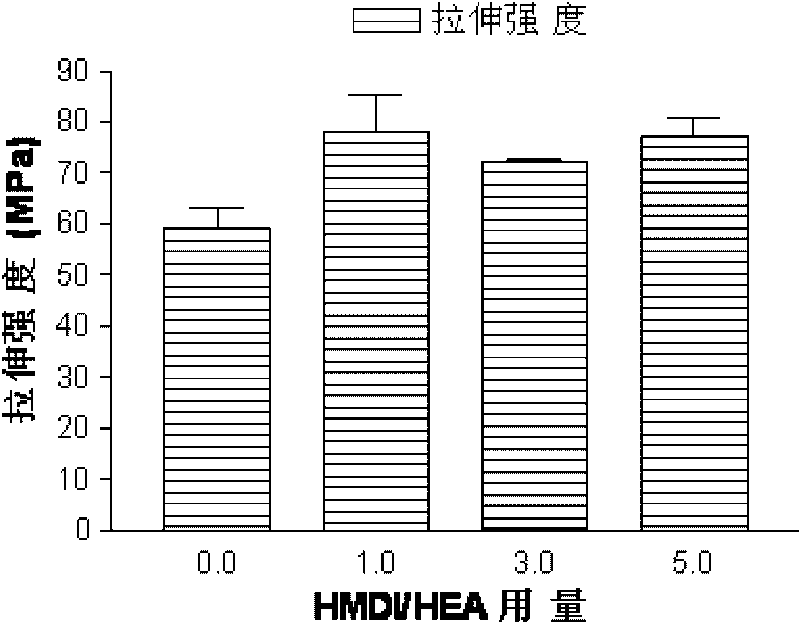

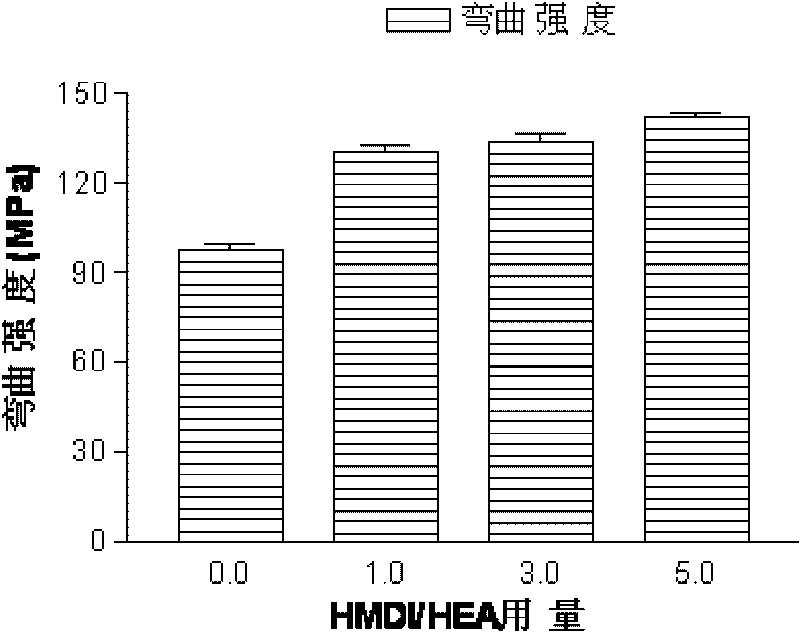

[0022]Preparation method: cut bamboo fiber into 2.54cm long, dry in an oven at 103°C until dry, mix UPE resin with initiator, t...

Embodiment 2

[0027] Raw materials: Unsaturated polyester (UPE) resin and initiator methyl ethyl ketone peroxide MEKP-94 were purchased from AOC Company (Collierville, TN, USA); bamboo fiber was provided by the Bamboo Engineering Research Center of Zhejiang Forestry University (the bamboo fiber was mechanically rolled prepared by method); modifier 1,6-hexamethylene diisocyanate was purchased from Sigma-Aldrich Company (Milwaukee, WI, USA), anhydrous ethyl acetate was purchased from EMD Chemicals Incorporated (Gibbstown, NJ, USA), acrylic acid-2- Hydroxyethyl ester was purchased from TCI America (Portland, OR, USA).

[0028] Bamboo fiber composite material:

[0029] Raw materials: UPE resin is o-phthalic unsaturated polyester resin (its main components include ethylene glycol, propylene glycol, maleic anhydride, phthalic anhydride and styrene, etc.).

[0030] Preparation method: cut bamboo fiber into 2.54cm long, dry in an oven at 103°C until dry, mix UPE resin with initiator, then mix even...

Embodiment 3

[0035] Raw materials: Unsaturated polyester (UPE) and initiator methyl ethyl ketone peroxide MEKP-94 were purchased from AOC Company (Collierville, TN, USA); bamboo fiber was provided by the Bamboo Engineering Research Center of Zhejiang Forestry University (the bamboo fiber was mechanically rolled Preparation); modifier 1,6-hexamethylene diisocyanate was purchased from Sigma-Aldrich Company (Milwaukee, WI, USA), anhydrous ethyl acetate was purchased from EMD Chemicals Incorporated (Gibbstown, NJ, USA), 1,6-hexamethylene Diisocyanate / 2-hydroxyethyl acrylate was purchased from TCI America (Portland, OR, USA).

[0036] Bamboo fiber composite material:

[0037] Raw materials: UPE resin is o-phthalic unsaturated polyester resin (its main components include ethylene glycol, propylene glycol, maleic anhydride, phthalic anhydride and styrene, etc.).

[0038] Preparation method: cut bamboo fiber into 2.54cm long, dry in an oven at 103°C until dry, mix UPE resin with initiator, then m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com