Novel energy-saving environment-friendly light-weight stone-simulating brick and manufacture method thereof

A technology of energy saving, environmental protection and production method, applied in the fields of architectural decorative wall tiles and architectural decorative materials, can solve the problems of increased product cost, unsafe installation of high-rise buildings, high price, etc., achieve energy saving in manufacturing process, reduce daily energy consumption, production consumption low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

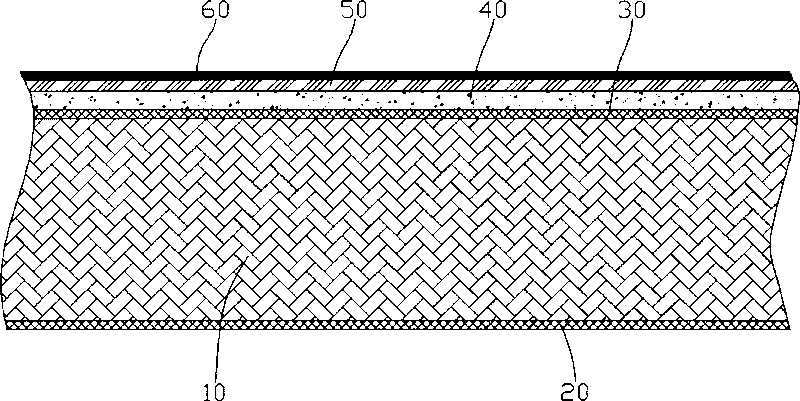

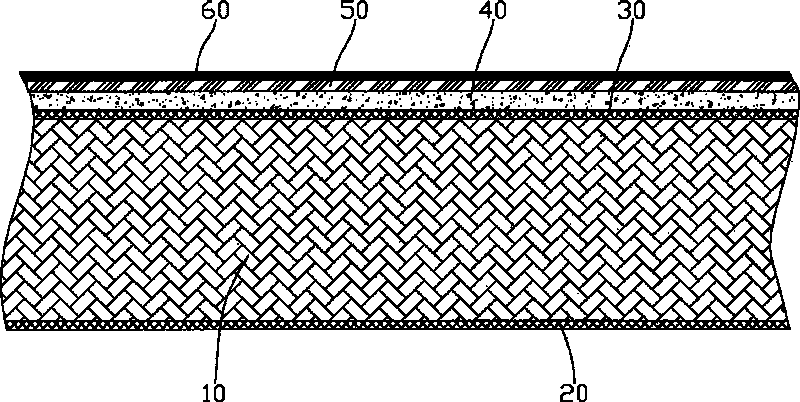

[0016] See attached figure 1 Shown: the novel energy-saving and environment-friendly lightweight imitation stone wall brick of the present invention is to be base material with heat-insulating Styrofoam (being commonly called as foam), at first meets design requirement Styrofoam (density is 30~58Kg / m 3 , the thickness is 5mm~10mm) the bottom surface of 10 attaches a layer of glass fiber net, is coated with thin cement mortar at the same time and glass fiber net and Styrofoam 10 are closely connected together, forms the lower net sand layer 20; After the layer 20 hardens, carry out the same operation on the front of Styrofoam 10 to make the upper sand layer 30, and the thickness of the lower sand layer 20 and the upper sand layer 30 is preferably 0.4mm~0.9mm. Afterwards, coat the cement mortar layer 40 with a thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com