High-power radiating module

A heat dissipation module and metal technology, applied in lighting and heating equipment, cooling/ventilation/heating transformation, cooling/heating devices of lighting devices, etc., can solve problems such as brittle fracture and unfavorable life of electronic parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

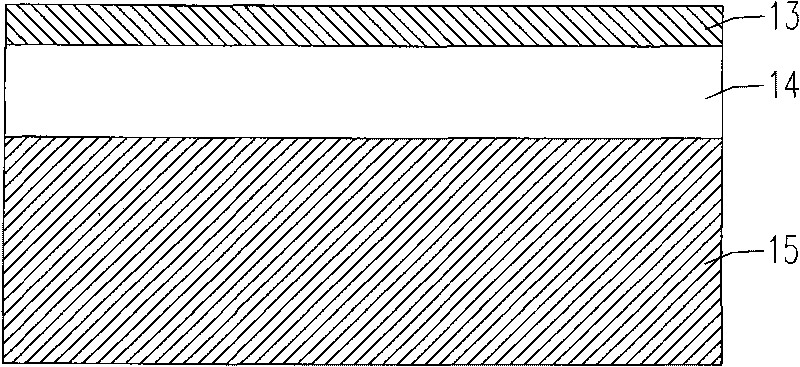

[0035] figure 1 A schematic cross-sectional view of the heat dissipation module according to the first embodiment of the present invention is shown. Such as figure 1 As shown, the heat dissipation module of this embodiment includes: a thin metal upper layer 13 , a ceramic substrate 14 , and a thick metal lower layer 15 .

[0036] In this embodiment, the ceramic substrate 14 is formed of alumina or aluminum nitride, however, the present invention is not limited thereto, and it can be easily understood from the following description that other materials can also be used to form the ceramic substrate 14 .

[0037] The metal upper layer 13 is located above the ceramic substrate 14 . The material of the metal upper layer 13 is selected from the group consisting of gold, silver, copper and alloys thereof. The thickness of the metal upper layer 13 is between 0.1 mm (millimeter) and 1 mm, more preferably between 0.2 mm and 0.6 mm. There may be one or more lines or contacts (not sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com