Aeration method for improving film pollution control function

A membrane fouling and aeration technology, applied in water aeration, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problems of high energy consumption in operation, save operating costs, save aeration energy consumption, and can Strong implementation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

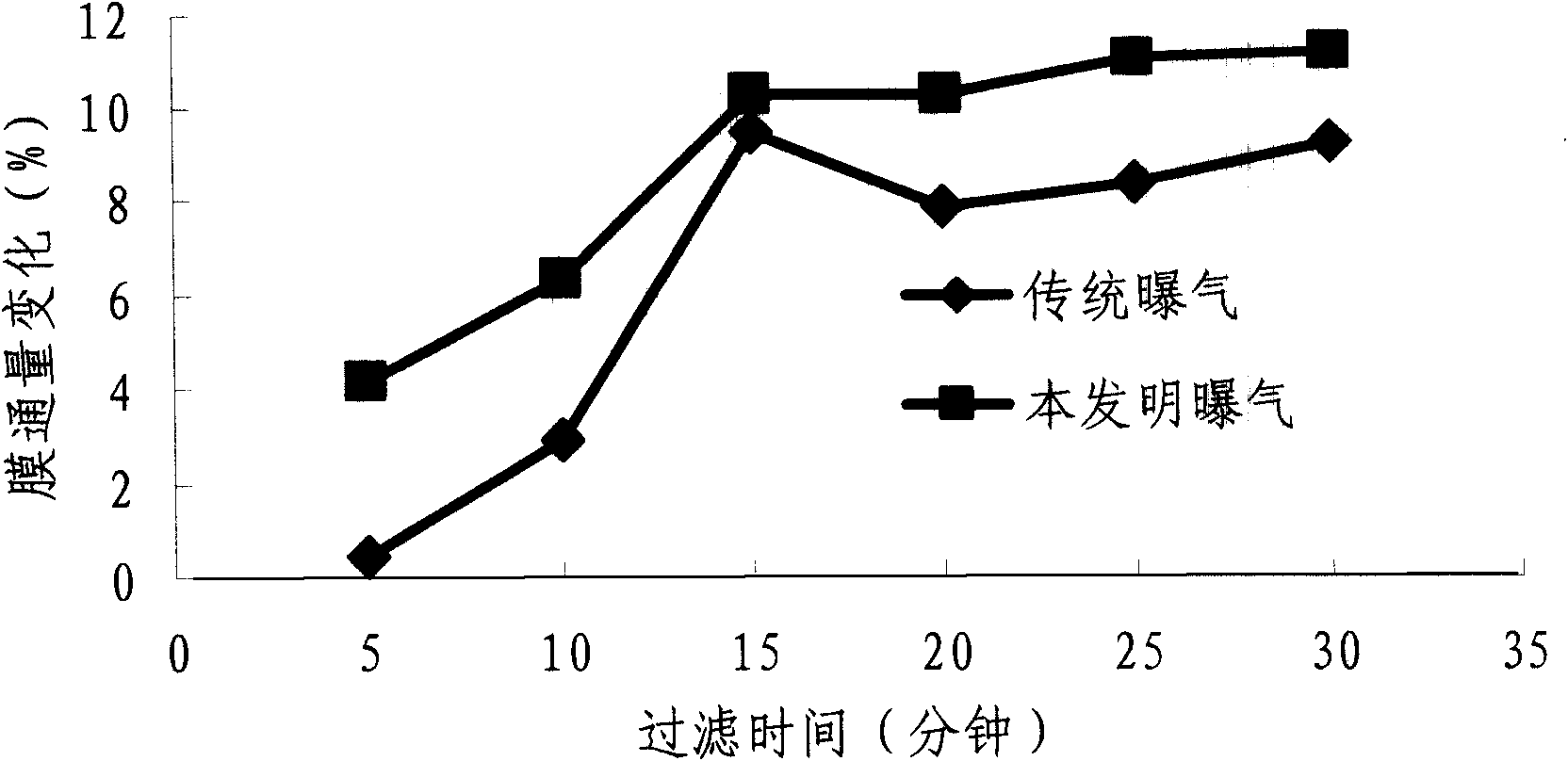

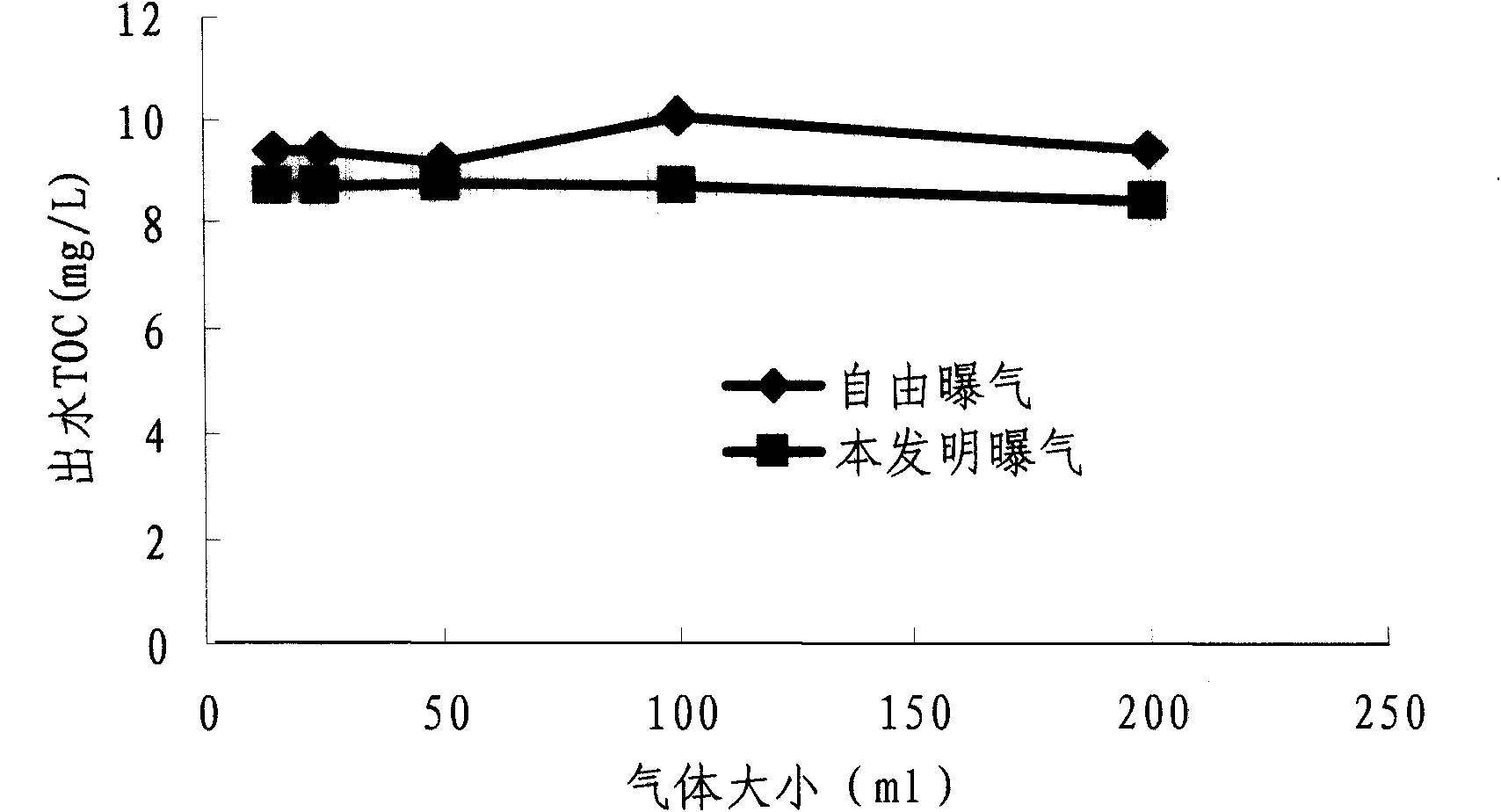

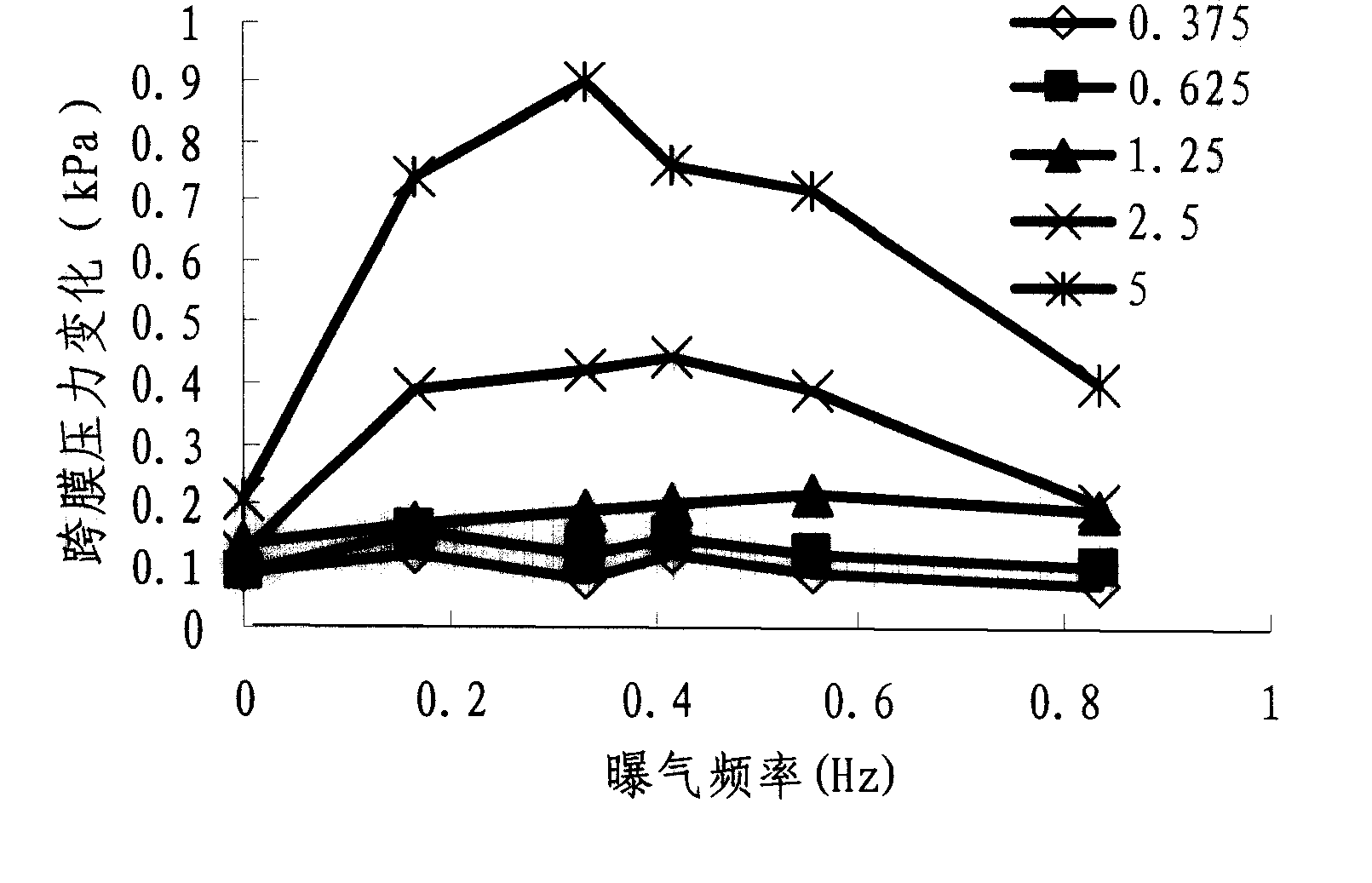

[0018] Within the purview of the present invention, the plug flow aeration technology involved in the present invention is compared with the traditional free aeration method. The plug flow aeration technology involved in the present invention improves membrane flux, membrane filtration effect and anti-pollution effect, etc. It has obvious technical advantages.

[0019] 1. Increased membrane flux

[0020] Taking the flat membrane module as an example, the membrane material is a flat membrane provided by a certain company, the membrane aperture is 0.3um, the effective filtration area of the membrane is 0.25 square meters, the length is 800mm, the width is 300mm, and the membrane spacing is 10mm. The plug flow aeration method involved in the present invention The technical parameters of medium aeration are that the single bubble size is 400ml, and the aeration frequency is 0.42Hz. For the water sample filtration of tap water and ultrapure water (1:1), self-pressurized immersion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com