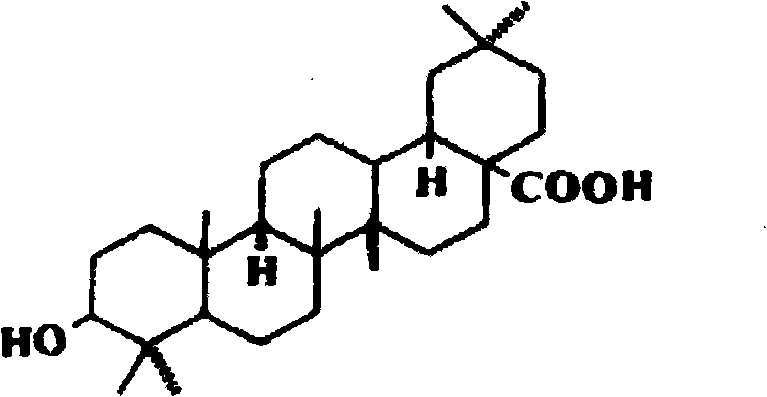

Preparation method of oleanolic acid

A technology of oleanolic acid and microfiltration is applied in the field of preparation of oleanolic acid, which can solve the problems of large dosage, low extraction selectivity, large consumption of solvent and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Take 10 kg of fresh Ligustrum lucidum leaves (1.2% oleanolic acid content), add 100 L of supersaturated lime water, decoct for 2 hours, add 100 L of supersaturated lime water to the filtered insoluble matter, decoct for 2 hours, and filter. Combine the two medicinal solutions, add hydrochloric acid, adjust the pH to about 3, and filter with suction to obtain 218 g of the precipitated crude triterpene acid. Add 900ml of 50% methanol for reflux extraction for 1.5 hours, filter while hot, and filter the filtrate through a ceramic membrane with a pore size of 50-500nm, and then through a nanofiltration membrane with a molecular weight cutoff of 300-500, and dry under reduced pressure to obtain 93g of oleanolic acid. The purity was 98.5%.

Embodiment 2

[0021] Take 10kg of fresh Ligustrum lucid leaves (1.2% oleanolic acid content), add 110L of supersaturated lime water, decoct for 2.5 hours, add supersaturated lime water to the filtered insoluble matter, and operate twice under the same conditions. Combine the three liquid medicines, add sulfuric acid, adjust the pH to about 3, and filter with suction to obtain 223 g of the precipitated crude triterpene acid. Add 1000ml of 55% methanol for reflux extraction for 2 hours, filter while hot, and filter the filtrate through a ceramic membrane with a pore size of 50-500nm, and then through a nanofiltration membrane with a molecular weight cut-off of 300-500. Dry under reduced pressure to obtain 107g of oleanolic acid. The purity was 98.2%.

Embodiment 3

[0023] Take 10kg of fresh Ligustrum lucid leaves (with oleanolic acid content 1.1%), add 110L of supersaturated lime water, decoct for 3 hours, add supersaturated lime water to the filtered insoluble matter, and operate once under the same conditions. Combine the two medicinal solutions, add phosphoric acid, adjust the pH to about 2, and filter with suction to obtain 213 g of the precipitated crude triterpene acid. Add 900ml of 60% methanol for reflux extraction for 1.5 hours, filter while hot, and filter the filtrate through a ceramic membrane with a pore size of 50-500nm, and then through a nanofiltration membrane with a molecular weight cutoff of 300-500, and dry under reduced pressure to obtain 96g of oleanolic acid. The purity was 98.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| specific rotation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com