Method for preparing strontium aluminate long-persistence luminescent materials based on nanometer fusing assistants

A technology of luminescent materials and fluxes, which is applied in the direction of luminescent materials, chemical instruments and methods, sustainable manufacturing/processing, etc., can solve the problems of high energy consumption, high reaction temperature, and long reaction time, so as to promote uniform growth and improve Luminous center density, slow decomposition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

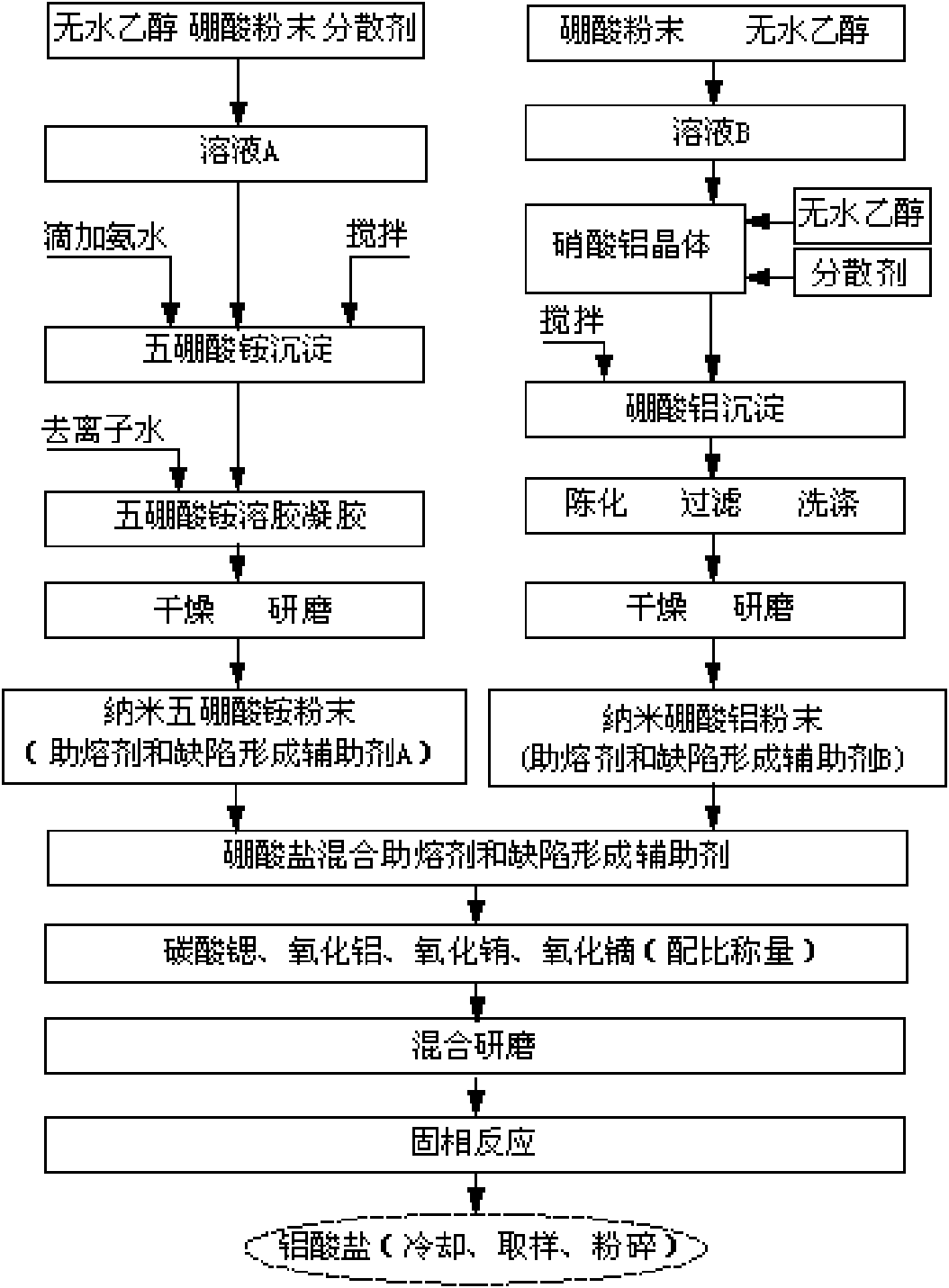

[0056] combine figure 1 , the process and operation steps of preparing strontium aluminate long-lasting luminescent material based on nano-flux are as follows:

[0057] (1) First measure 200ml of analytically pure absolute ethanol solution and put it into beaker A, according to the molar ratio H of the composition mixture 3 BO 3 : NH 3 ·H 2 O=5:1 Weigh the corresponding analytically pure raw material boric acid H 3 BO 3 3.0917g, it is added in the beaker A that dehydrated alcohol solution is housed, and in beaker A, add 10 polyethylene glycol solutions as dispersant, stir with glass rod and make boric acid fully dissolve, make solution A; Simultaneously , First measure 200ml of analytically pure absolute ethanol solution and put them into beaker B 1 , Beaker B 2 in, according to H 3 BO 3 : Al(NO 3 ) 3 9H 2 O=1:2 Weigh the corresponding analytically pure raw material boric acid H 3 BO 3 1.2367g, add it to beaker B with absolute ethanol solution 1 , stir with a gl...

Embodiment 1

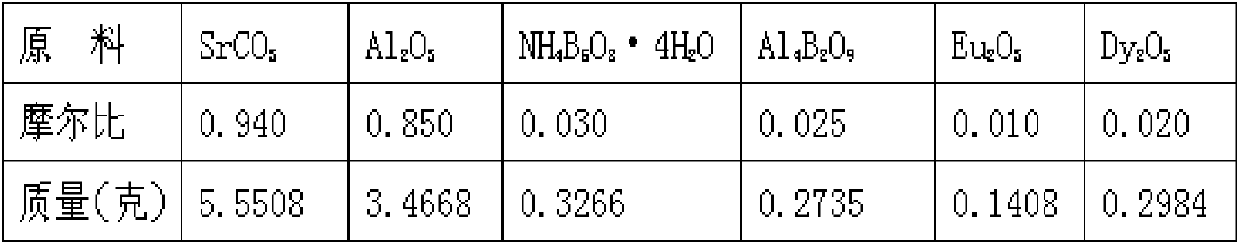

[0072] 1. the mixed material of step (1)-(7) gained in the general implementation mode presses figure 2 The ratio of raw materials in the embodiment 1 table is selected;

[0073] ② Fully grind the above-mentioned mixed materials in an agate mortar for 2 hours to make them evenly mixed, and then put the evenly mixed materials into the corundum crucible;

[0074] ③Use carbon powder as a reducing agent and make a closed carbon tank. Put the above-mentioned corundum crucible filled with materials into the closed carbon tank and seal it. Put the closed carbon tank in a high-temperature furnace and heat it to 1100°C. Hours, cooling with the furnace temperature, taking out the bulky solid reaction product, pulverizing the reaction product to obtain a near-yellow-green long-lasting strontium aluminate product;

[0075] ④ After the above strontium aluminate product is irradiated with 365nm ultraviolet rays for 10 minutes, it will show a green afterglow glow in the dark; when the ligh...

Embodiment 2

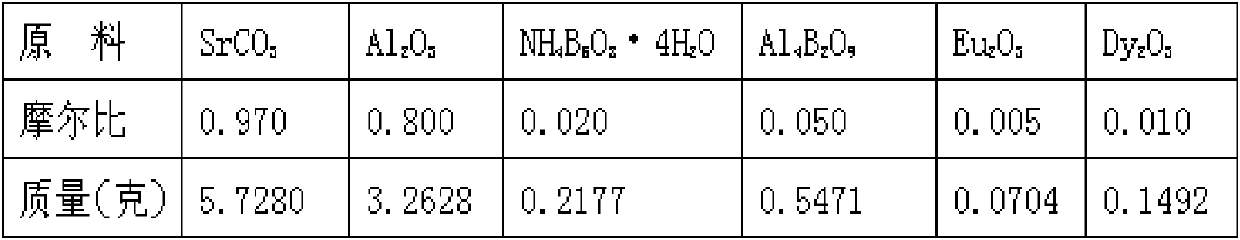

[0077] 1. the mixed material of step (1)-(7) gained in the general implementation mode presses image 3 The ratio of raw materials in the embodiment 2 table is selected;

[0078] ② Fully grind the above-mentioned mixed materials in an agate mortar for 2 hours to make them evenly mixed, and then put the evenly mixed materials into the corundum crucible;

[0079] ③Use carbon powder as a reducing agent and make a closed carbon tank. Put the above-mentioned corundum crucible filled with materials into the closed carbon tank and seal it. Hours, cooling with the furnace temperature, taking out the bulky solid reaction product, pulverizing the reaction product to obtain a near-yellow-green long-lasting strontium aluminate product;

[0080] ④ After the above strontium aluminate product is irradiated with 365nm ultraviolet rays for 10 minutes, it will show a green afterglow glow in the dark; when the light source is removed, the luminous brightness of the strontium aluminate product t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com