Titanium oxyoxalate electrorheological fluid and preparation method thereof

A technology of titanyl oxalate and electrorheological fluid, applied in the direction of lubricating composition and the like, can solve the problems of inability to reach the level of industrial application, low shear strength, etc., and achieve the effects of short cycle, low cost and good application prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Mix 17.4ml tetrabutyl titanate and ethanol at a molar ratio of 1:50, stir evenly, and then add hydrochloric acid dropwise to control the pH of the solution to 2.0 to obtain a stable solution A; Dissolve in ethanol and prepare 1mol / l oxalic acid ethanol solution B; put solution A on a mixer and stir, take 50ml of solution B and drop it into solution A, gradually forming a precipitate; after the reaction is complete, filter the formed precipitate After drying, titanyl oxalate particles with sizes ranging from nanometers to micrometers are obtained. The XRD patterns of titanyl oxalate particles are as follows Figure 5 shown, from Figure 5 It can be seen that the titanyl oxalate particles are in an amorphous state; Image 6 is the infrared transmission spectrum of the titanyl oxalate particles, by Image 6 It can be seen that the characteristic absorption peaks of its carboxyl and hydroxyl groups.

[0027] The titanyl oxalate particles are uniformly mixed with methyl ...

Embodiment 2

[0029] Mix 5.5ml of titanium tetrachloride and isopropanol in a molar ratio of 1:40, stir evenly, then add nitric acid dropwise to control the pH value of the solution to 1.5, to obtain a stable solution A; Dissolve in isopropanol, and prepare 0.5mol / l oxalic acid isopropanol solution B; put solution A on a mixer and stir, take 100ml of solution B and drop it into solution A, and gradually form a precipitate; after the reaction is complete, put The resulting precipitate is filtered and then dried to obtain titanyl oxalate particles with the required nanometer to micrometer size distribution.

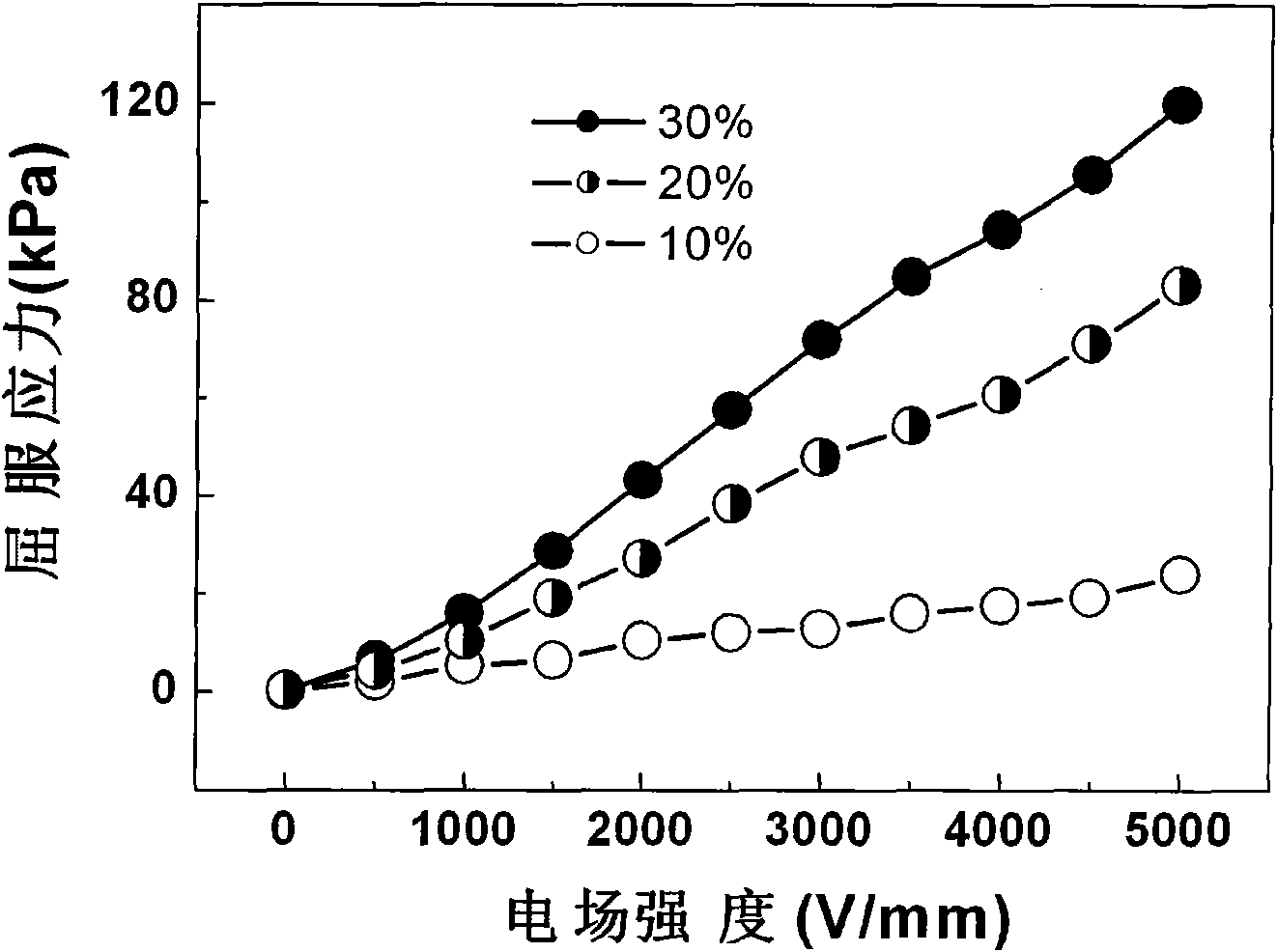

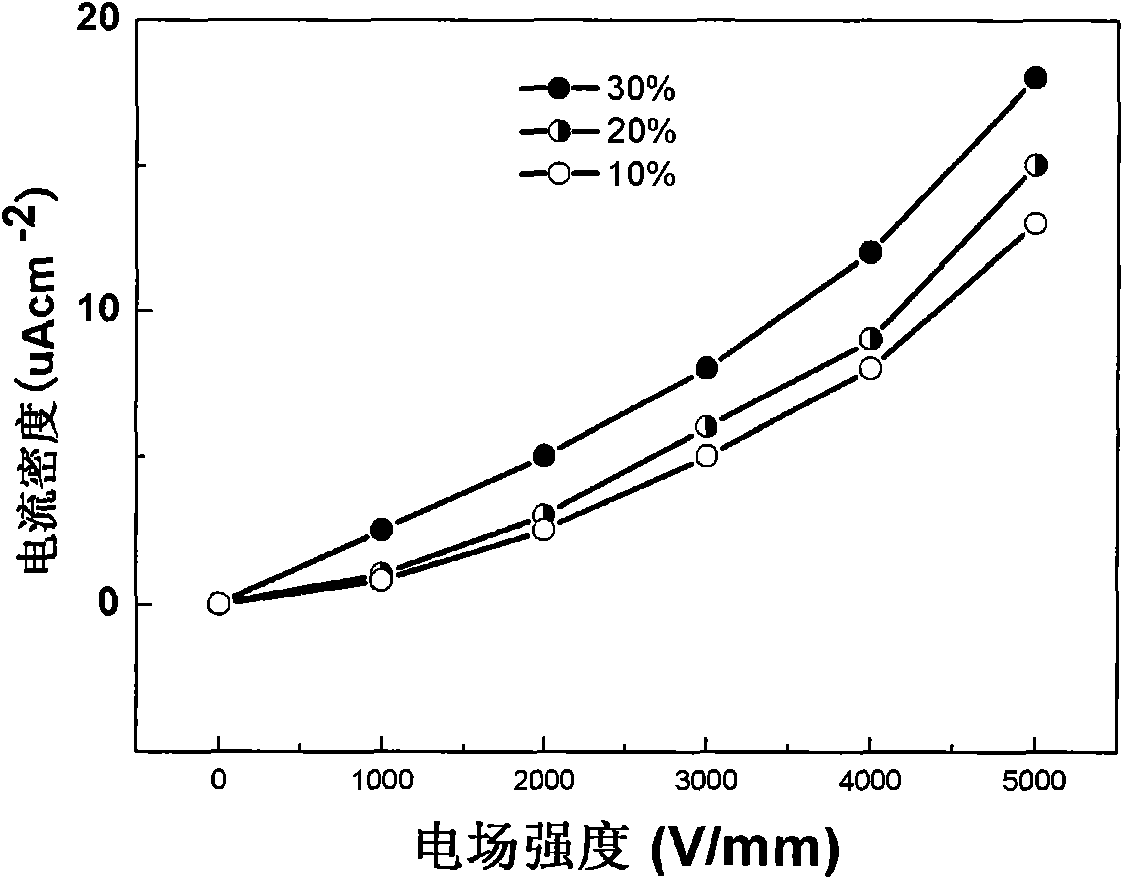

[0030] The titanyl oxalate particles were uniformly mixed with hydroxyl silicone oil to prepare titanyl oxalate electrorheological fluids with a volume concentration of 15%, 20% and 30%. When the applied electric field V=4.0kV / mm, the yield strength of 15% electrorheological fluid is 16kPa, and the current density is 8uA / cm 2 ; The yield strength of 20% electrorheological fluid can reac...

Embodiment 3

[0032] Mix 17.4ml tetrabutyl titanate and propanol in a molar ratio of 1:30, stir evenly, then add hydrochloric acid or nitric acid dropwise to control the pH value of the solution to 1.0 to obtain a stable solution A; Amount of oxalic acid was dissolved in propanol to prepare 0.5mol / l oxalic acid propanol solution B; put solution A on a mixer and stir it, take 100ml solution B and drop it into solution A, gradually forming a precipitate; after the reaction was complete, put The resulting precipitate is filtered and then dried to obtain titanyl oxalate particles with the required nanometer to micrometer size distribution.

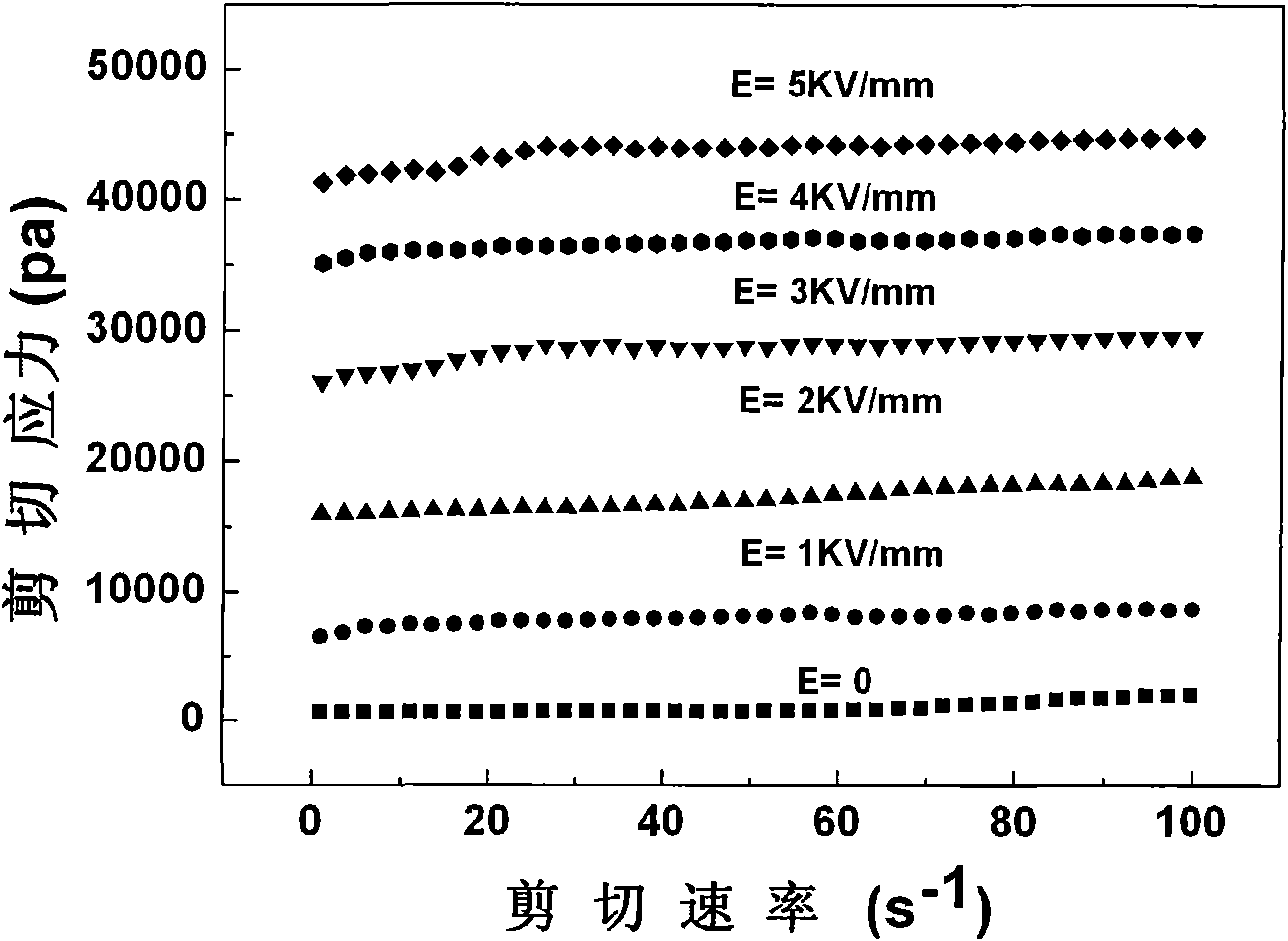

[0033] The titanyl oxalate particles are uniformly mixed with methyl silicone oil to prepare titanyl oxalate electrorheological fluids of the present invention with volume concentrations of 10%, 20% and 30%. When the applied electric field V=5.0kV / mm, the yield strength of 10% electrorheological fluid is 10kPa, the shear strength is 5kPa, and the current de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield stress | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com