Method for performing scattering predictive control on multi-time-scale complex huge system

A multi-time scale, predictive control technology, applied in adaptive control, general control system, control/regulation system, etc., can solve problems such as control performance deterioration, regulation amount lag, and increased energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

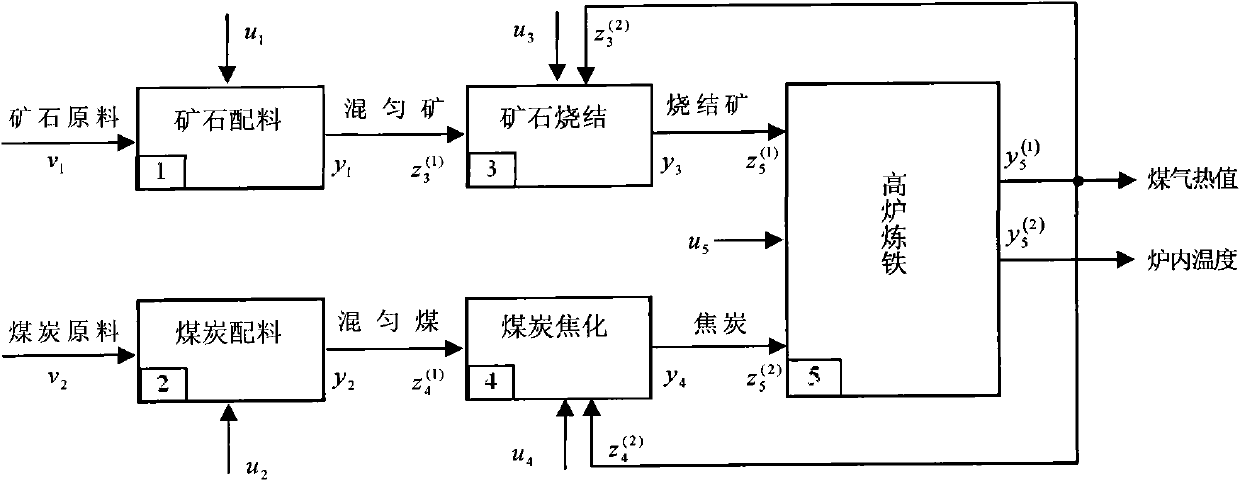

[0121] figure 1 The ironmaking production process shown is a typical complex large-scale system, which consists of five processes (subsystems) including ore batching process, coal batching process, ore sintering process, coal coking process, and blast furnace ironmaking process, involving a large number of processes Variables and complex associations, and the dynamic characteristics of each subsystem vary greatly. When any production link in the system is subject to external disturbances or changes in operating conditions, other links will also deviate from the normal production state due to the correlation between subsystems, and it is difficult to effectively overcome this deviation only by local control.

[0122] The present invention adopts the production data of a certain iron and steel plant, and uses the proposed decentralized predictive control method for complex large-scale systems with multiple time scales to carry out global coordinated optimization control calculat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com