Fabrication process and device of syrup picture

A production process and sugar syrup technology, which is applied in the confectionary industry, confectionery, decorative arts, etc., can solve the problems of difficulty in controlling the heat, easy to be diluted by moisture, and inability to use, so as to save manpower and ensure product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

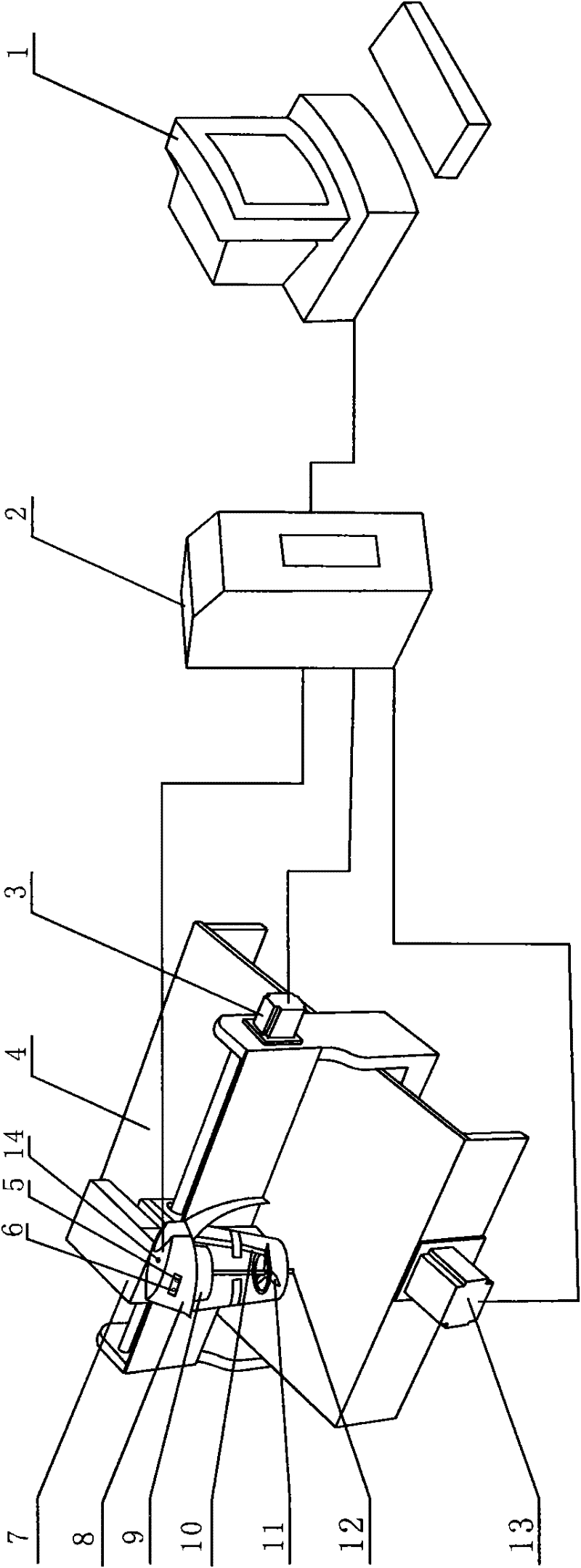

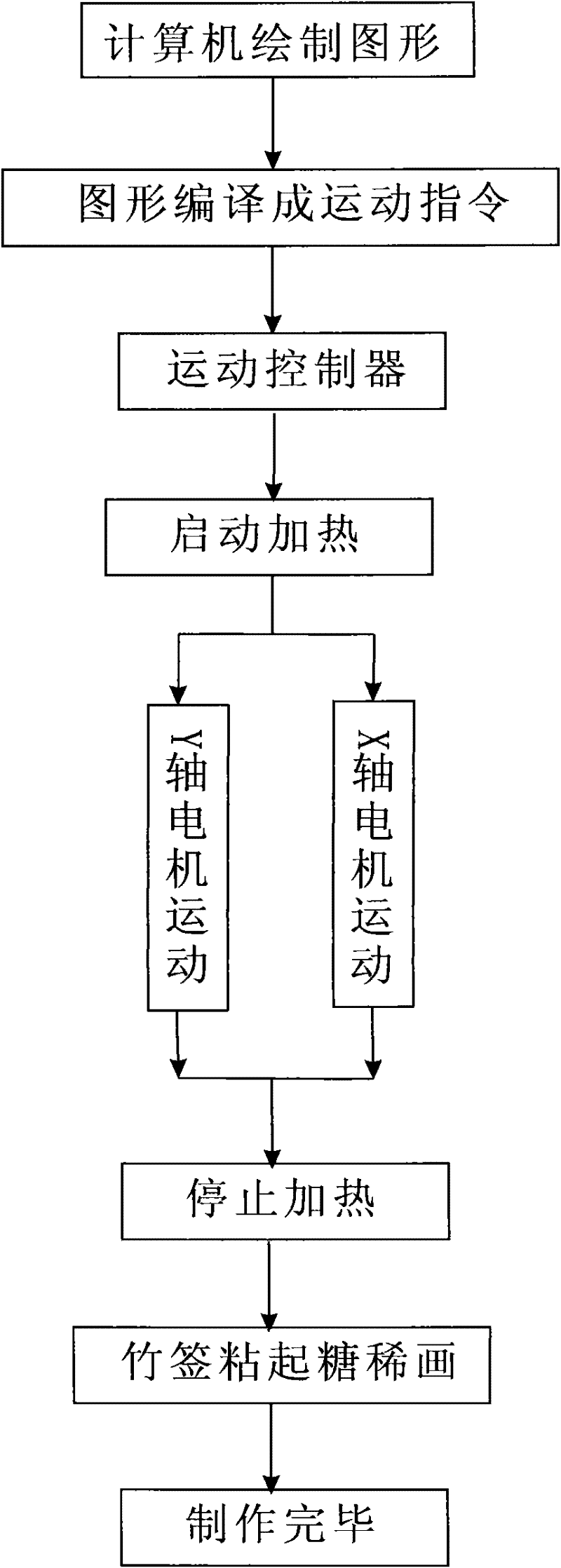

[0031] figure 1 In this example, a two-axis CNC engraving machine is used as the main machine 4 of the CNC syrup making machine, and the microcomputer temperature-controlled heating device 8 is set on the main shaft 7 of the main machine. The upper cover of the microcomputer temperature-controlled heating device 8 is provided with a stirring motor 9, heating Pipe 10, the stirring motor shaft is connected to the stirrer 11, and the upper cover of the microcomputer temperature-controlled heating device 8 is provided with an audible and visual alarm device 14, a start button 6, and an emergency stop button 5; The distance between the bottom of the device 8 is preferably 0.2-0.6 mm; the microcomputer temperature-controlled heating device 8 is connected to the signal of the motion controller in the control cabinet 2, and the X-axis motor 3 and Y-axis motor 13 of the host are connected to the motor driver signal in the control cabinet ; The motion controller in the control cabinet 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com