Surface color processing method for vehicle wheels and wheels thereof

A color registration and wheel technology, which is applied to special surfaces, pre-treated surfaces, and devices for coating liquids on surfaces, can solve the problems of uneven interface, high processing costs, and poor appearance effects, and achieve simple process and low cost , the uniform effect of the interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] refer to figure 1 , a surface coloring method of a vehicle wheel, the surface coloring method comprising the following steps:

[0045] (1), first carry out surface treatment on the vehicle wheel, the wheel surface has a background color;

[0046] (2), and then spray a layer of peelable paint on the surface with the base color;

[0047] (3) After drying, peel off the strippable paint in the pattern area where the color needs to be changed;

[0048] (4), spray another layer of paint of another color;

[0049] (5) After drying, peel off the peelable paint except the pattern area to complete the color registration.

[0050] Explain as follows: The pattern area refers to the area that needs to be colored on the surface of the wheel according to the design. It can contain one picture, two pictures or even multiple pictures. Different pictures can be spaced from each other or overlapped (overlapping will cause color If the paint overlaps, it will produce a mixed color effe...

example 2

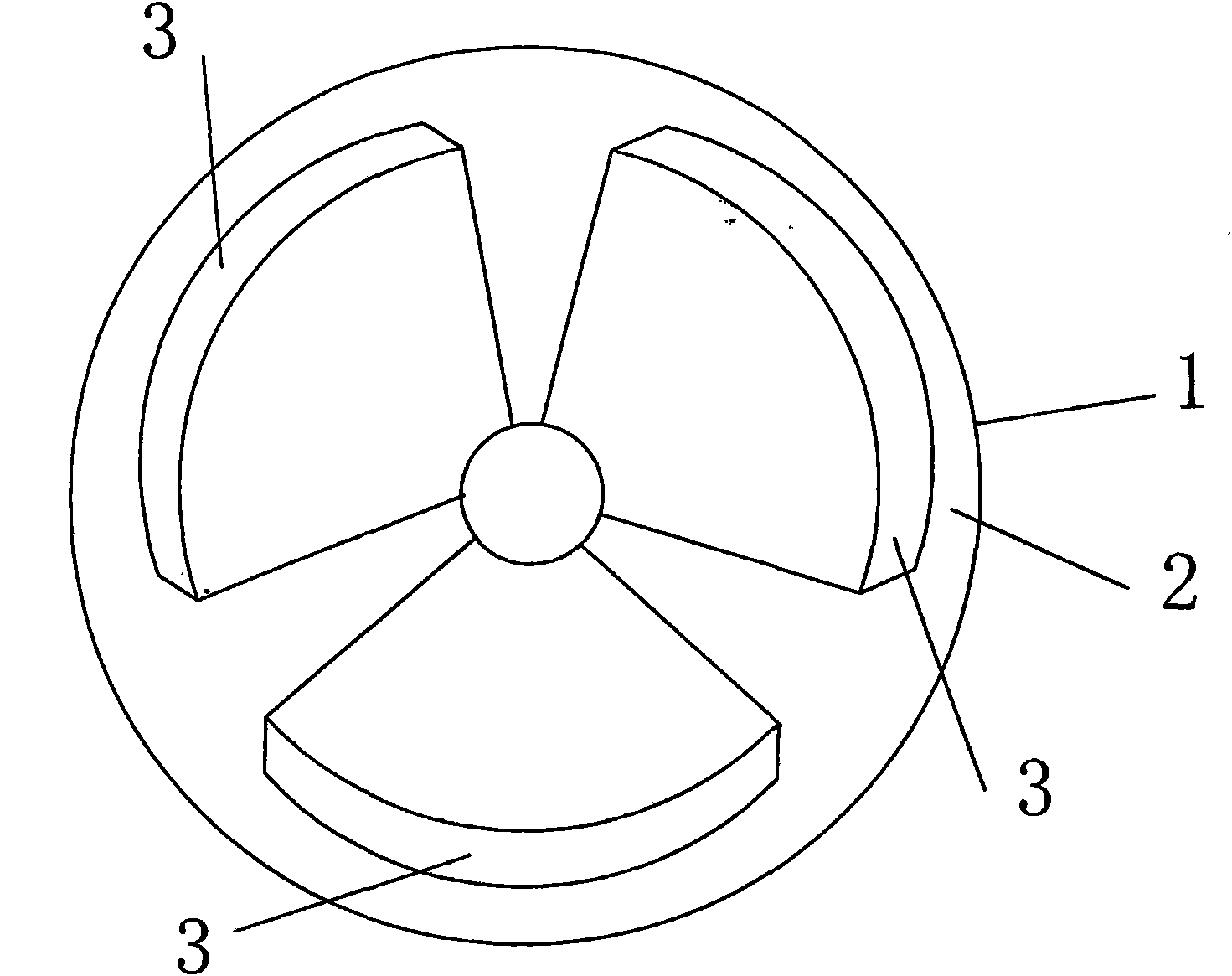

[0066] Example 2: if figure 1 The rim shown is sprayed with paint according to the normal process, and the process is as follows: pretreatment → powder spraying and drying → spraying silver white paint surface drying or drying → spraying varnish or transparent powder and drying. Pick out qualified products, spray them with perchlorethylene peelable paint, dry them by themselves or dry them, and cut them along with 3D laser cutting equipment. figure 1 Cut the contour line of area 2 to the bottom varnish layer, peel off the peelable paint attached to area 2, and then spray a layer of black polyester amino paint, peel off the rest of the peelable paint after the surface is dry, and then dry at high temperature Later, two-color wheels are available. It is also ok to peel off the rest of the peelable paint after drying at high temperature.

example 3

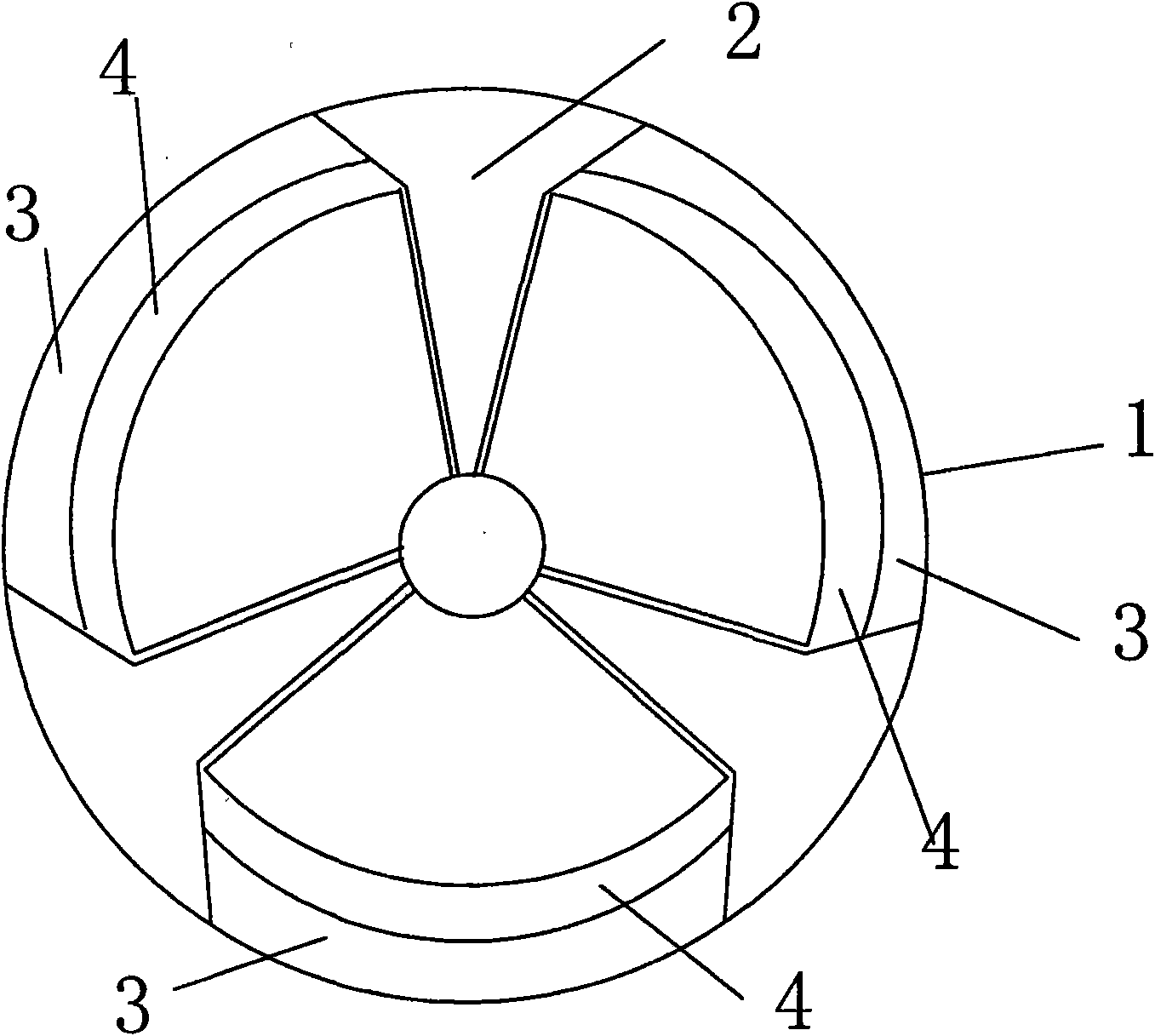

[0067] Example 3: if figure 2 The rim shown is sprayed with paint according to the normal process, and the process is as follows: pre-treatment → powder spraying and drying → spraying white plain paint and drying → pre-treatment after the three-car project → spraying varnish or transparent powder and drying. Pick out qualified products, spray nitrocellulose peelable paint, surface dry or dry at low temperature, and use three-dimensional laser cutting equipment to cut figure 2 Cut the contour line of area 3 to the bottom varnish layer, peel off the strippable paint attached to area 3, and then spray a layer of blue alkyd amino paint, peel off the rest of the strippable paint after the surface is dry, and then dry Finally, a three-color rim with the bright color of the car in area 2, blue in area 3, and white in area 4 can be obtained. It is also ok to peel off the rest of the peelable paint after drying at high temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com