Method for machining nanometer channel on microfluid chip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

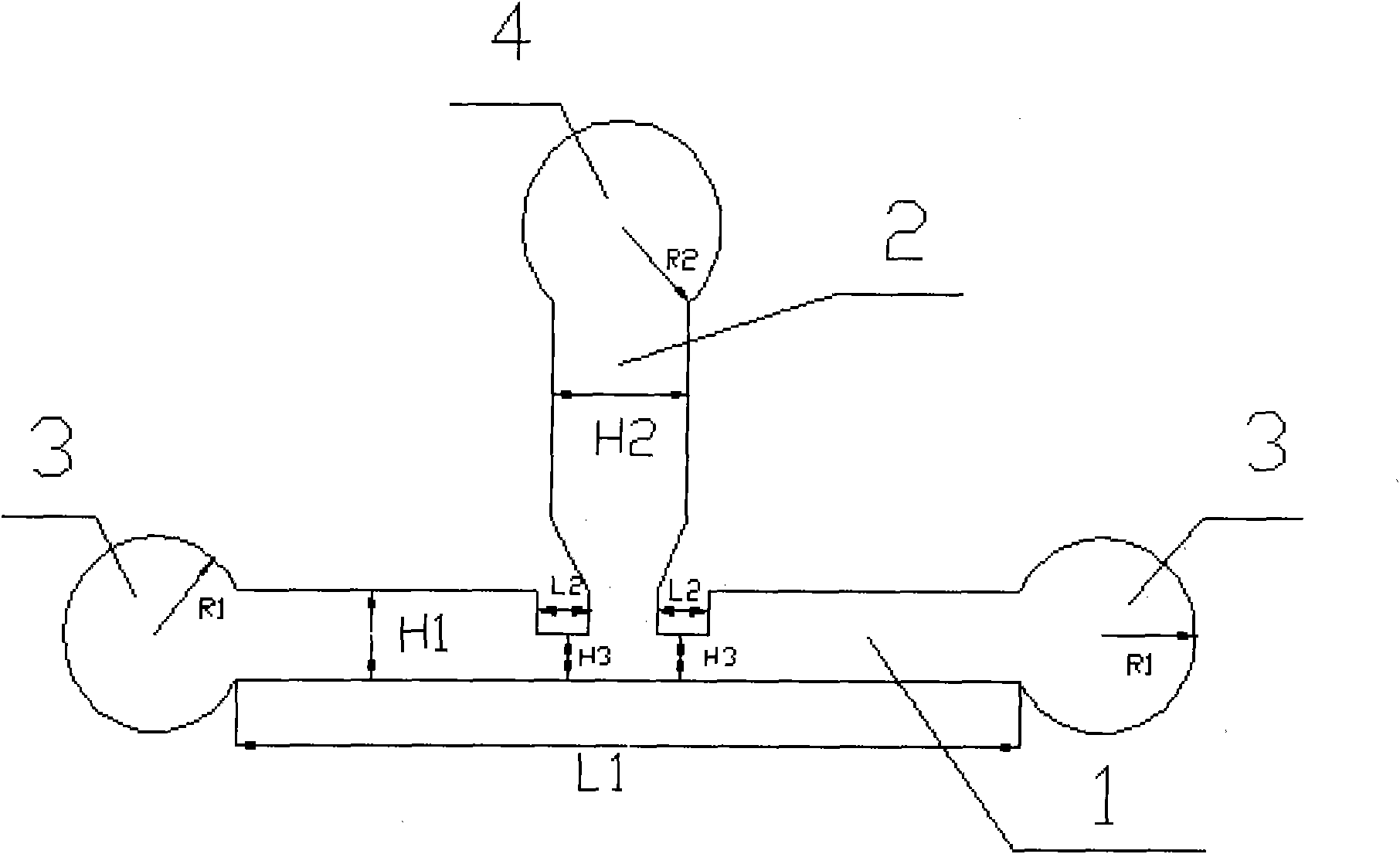

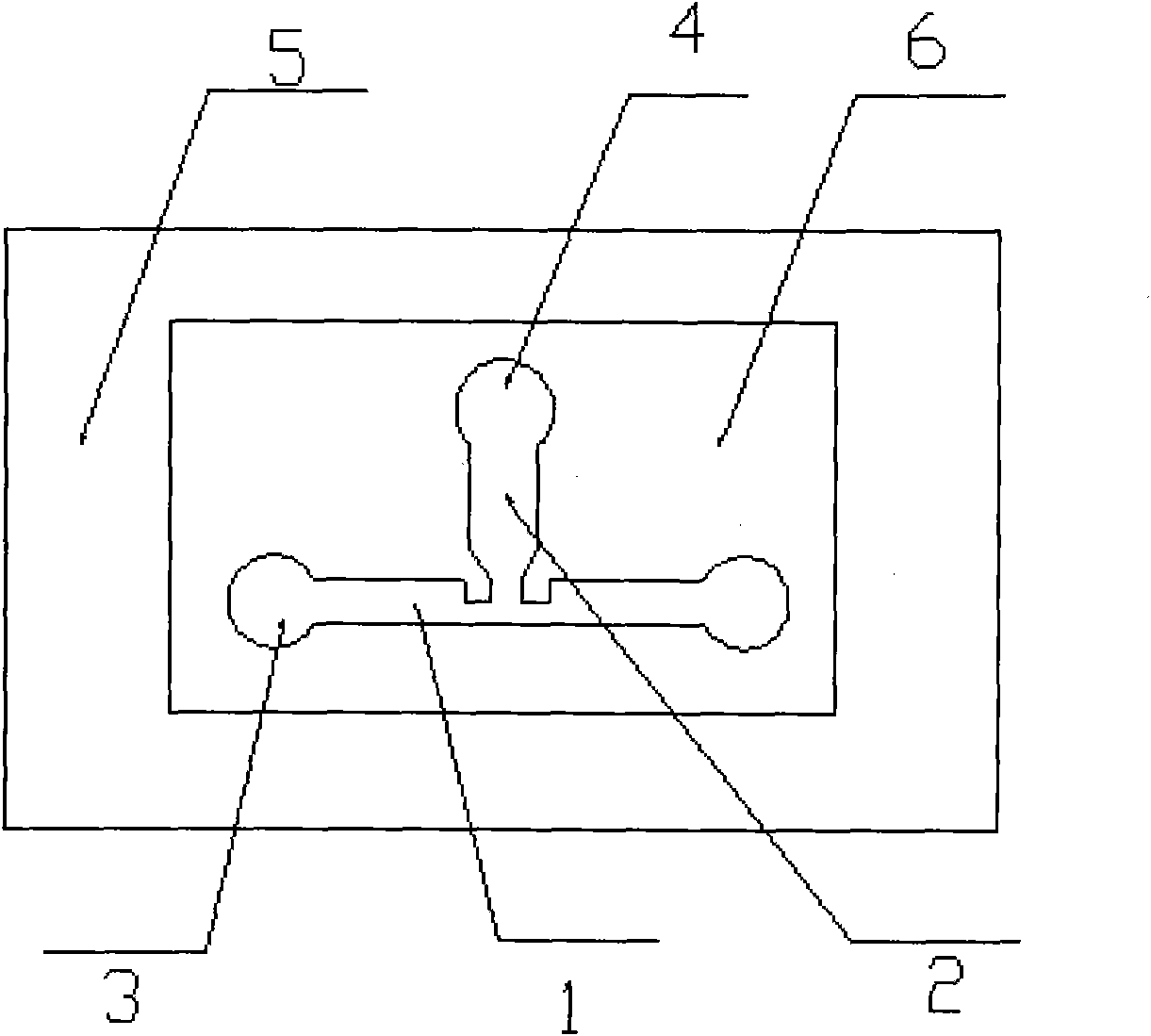

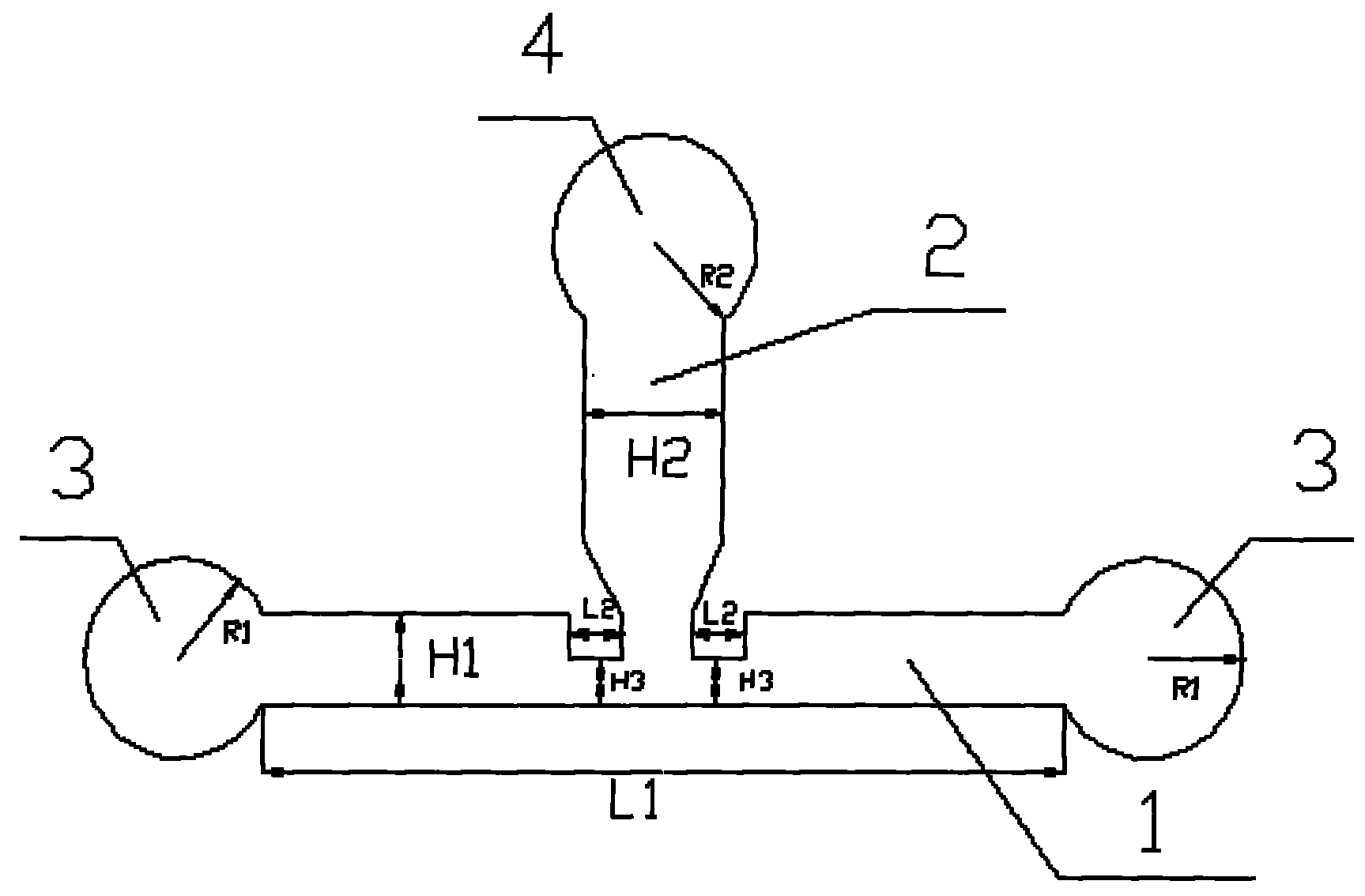

[0029] The present invention will be further described below in conjunction with the accompanying drawings. Such as Figure 1-2 As shown, a method for processing nanochannels on a microfluidic chip comprises the following steps:

[0030] A. Using lithography, that is, by printing a channel as a micron-scale mask, using SU-8 negative photoresist, and processing a main channel 1 and a mixed solution injection channel 2 on a silicon-based wafer by ultraviolet exposure Then cast polydimethylsiloxane (PDMS) on the wafer, and use a constant temperature vacuum furnace to cure for 3 to 4 hours at 70-80°C; peel off the PDMS from the wafer, and in the main channel 1 A buffer solution storage hole 3 is drilled at both ends of the buffer solution, and a mixed solution storage hole 4 is punched at the top of the mixed solution injection channel 2; the PDMS6 with the concave channel and the glass negative film 5 are sealed by air plasma. connected to form a chip with micron-scale channels...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com