Treatment method of waste slurry generated by gigging well and drilling

A treatment method and technology for waste mud, applied in the direction of dewatering/drying/concentrating sludge treatment, etc., can solve the problems of small treatment capacity, waste of land resources, surface soil, groundwater pollution, etc., achieve large treatment capacity, reduce treatment costs, The effect of solving the pollution problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

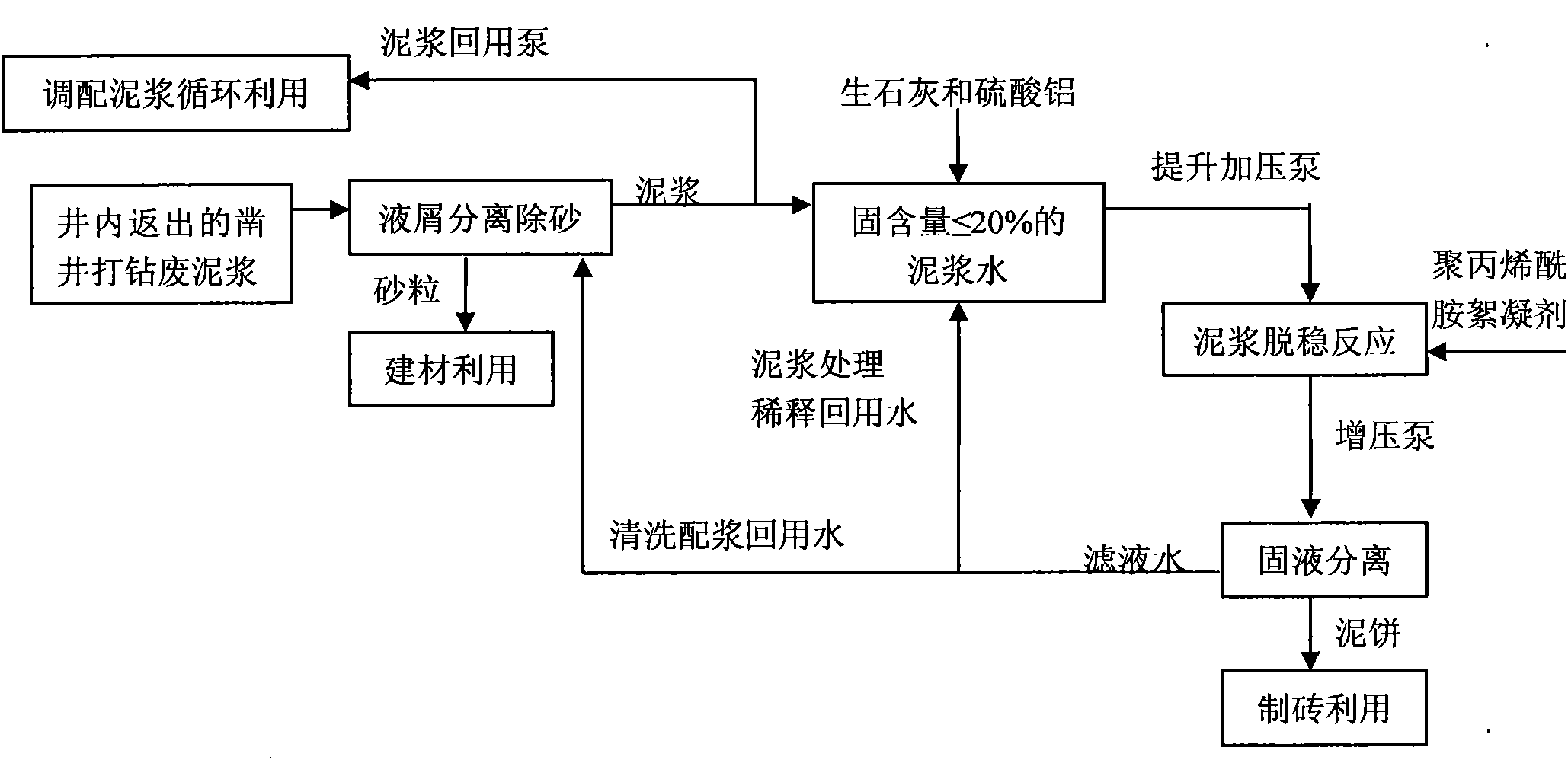

[0022] As shown in the attached figure, a treatment method for waste mud from sinking and drilling: the 1000m 3 Sinking and drilling waste mud is sent to the vibrating screen with spraying device, rinsed with water, liquid debris is separated and desanded, and the obtained sand (particle size ≥ 1mm) is recycled and reused as building materials. After desanding, the waste drilling and drilling mud is Enter the mud collection tank or mud pool, part of it is returned to the well for reuse, and the remaining drilling waste mud enters the static mixer, adds inorganic flocculant and water to dilute and stir to break down and obtain mud with a solid content of ≤20% (weight). Water, and then the obtained mud water is sent to the static mixer through the lifting booster pump (0.5MPa) and polyacrylamide flocculant is added, stirred, and the mud destabilization reaction is carried out at normal temperature and pressure. After the mud destabilization reaction is completed, Slurry water is...

Embodiment 2

[0025] It is basically the same as that of Example 1, except that the disposal amount of waste mud from sinking and drilling in the well is 900m 3 ;The cyclone centrifuge separation device is used for the separation of liquid debris; when adding inorganic flocculant and water to the waste drilling mud after sand removal, diluting and stirring to obtain mud water with a solid content of ≤20%, and mud destabilization reaction All completed in the mixing tank; lifting booster pump (0.3MPa); booster pump (0.2MPa); three parallel-connected screw filters are used for solid-liquid separation; the dosage of quicklime is per cubic meter of drilling waste Add 40kg to the mud, and the dosage of aluminum sulfate is 20kg per cubic meter of drilling waste mud; the polyacrylamide flocculant is cationic polyacrylamide, and the dosage of the aqueous solution of 2% cationic polyacrylamide is per cubic meter of drilling mud Add 20Kg of drilling waste mud; add inorganic flocculant and water to di...

Embodiment 3

[0027] It is basically the same as that of Example 1, except that the disposal amount of waste mud from sinking and drilling in the well is 800m 3 ; Lifting booster pump (0.2MPa); Booster pump (0.3MPa); A centrifuge is used for solid-liquid separation; the dosage of quicklime is 25kg per cubic meter of drilling waste mud, and the dosage of aluminum sulfate Add 20kg per cubic meter of drilling waste mud; polyacrylamide flocculant is anionic polyacrylamide, and the dosage of 2% weight concentration anionic polyacrylamide aqueous solution is 10kg per cubic meter of drilling waste mud; add inorganic When diluting the flocculant with water and stirring when adding polyacrylamide flocculant, the stirring speed is 50rpm, and the stirring time is 20min. The whole process takes about 45 minutes to complete.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com