Mn-Al-CNTs type alloy as well as preparation method and application method thereof

A mn-al-cnts, 1.mn-al-cnts technology, which is applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc. The effect of machinability, coercivity improvement, and magnetic properties improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] mn 50+x al 50-y (CNTs) y-x Mn in type alloy 51 al 46 (CNTs) 3 type alloy, wherein x=1, y=4, y-x=3, and the above CNTs are carbon nanotubes.

[0053] mn 51 al 46 (CNTs) 3 The preparation steps of type alloy are:

[0054] The first step, the configuration of raw materials

[0055] By atomic percentage Mn 51 al 46 (CNTs) 3 , Weigh the raw materials Mn, Al and CNTs, and add 7% Mn according to the mass percentage of Mn weighed according to the ratio of raw materials at the same time, to complete the configuration of raw materials. The purity of the three kinds of raw materials are all mass percentage ≥ 99.9%. The above CNTs are commercially available multi-walled carbon nanotubes prepared by chemical vapor deposition, with an inner diameter of 5-10 nm, an outer diameter of 25-70 nm, and a length of 5-60 microns;

[0056] The second step, melting and smelting of raw materials

[0057] Put the raw materials configured in the first step into the smelting furnace,...

Embodiment 2

[0073] mn 50+x al 50-y (CNTs) y-x Mn in type alloy 52 al 46 (CNTs) 2 type alloy, wherein x=2, y=4, y-x=2, and the above CNTs are carbon nanotubes.

[0074] mn 52 al 46 (CNTs) 2 The preparation steps of type alloy are:

[0075] The first step, the configuration of raw materials

[0076] Divided by atomic percentage Mn 52 al 46 (CNTs) 2 , except that raw materials Mn, Al and CNTs are weighed and more than 6% of the mass percentage of Mn taken by weighing Mn according to the ratio of raw materials is added during batching, other requirements are the same as in Example 1;

[0077] The second step, melting and smelting of raw materials

[0078] With embodiment 1;

[0079] The third step is to prepare Mn 52 al 46 (CNTs) 2 Master Alloy Ingot

[0080] Cool the homogeneous alloy smelted in the second step naturally to obtain Mn 52 al 46 (CNTs) 2 Master alloy ingot, ie Mn 52 al 46 (CNTs) 2 Die cast alloy.

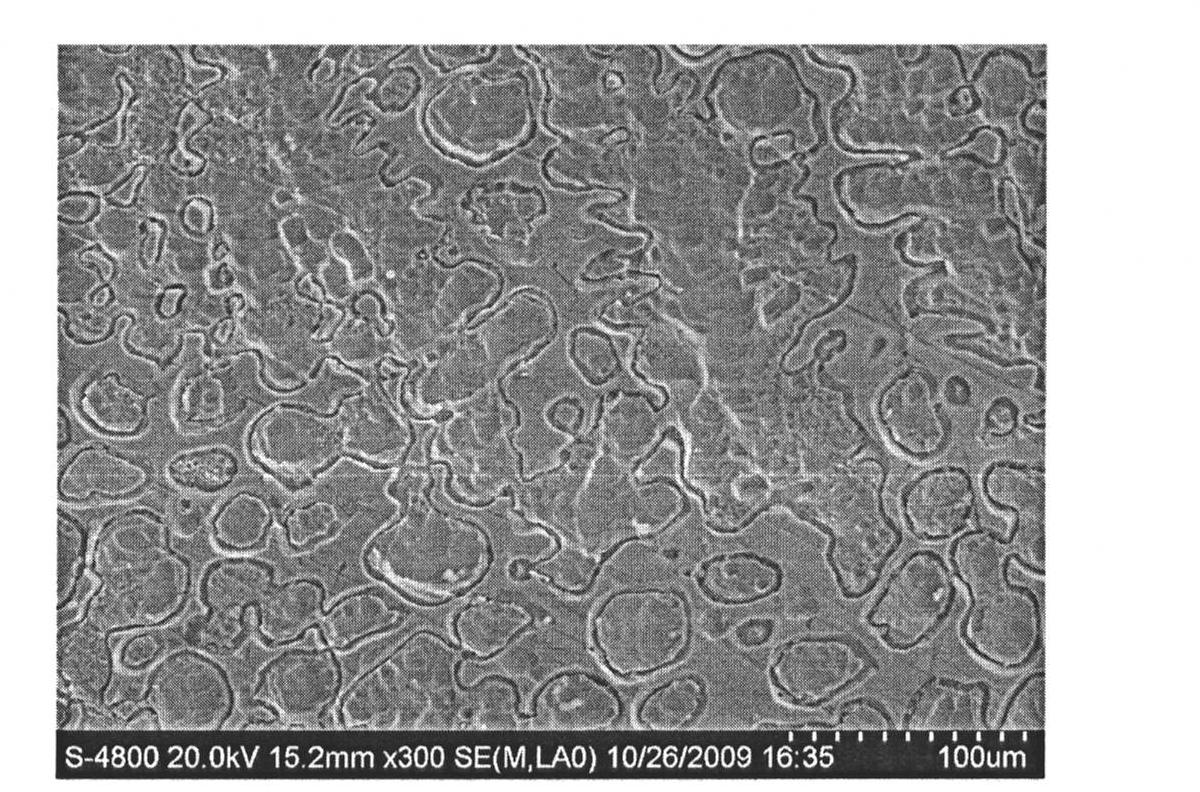

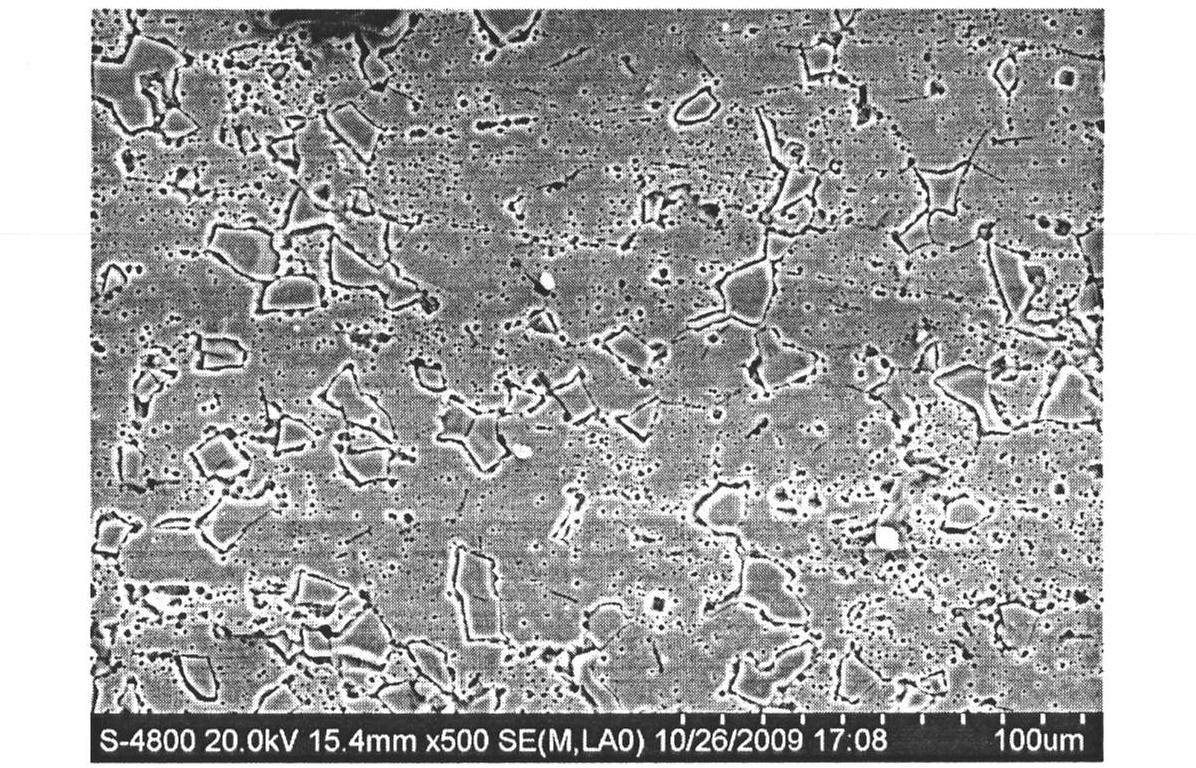

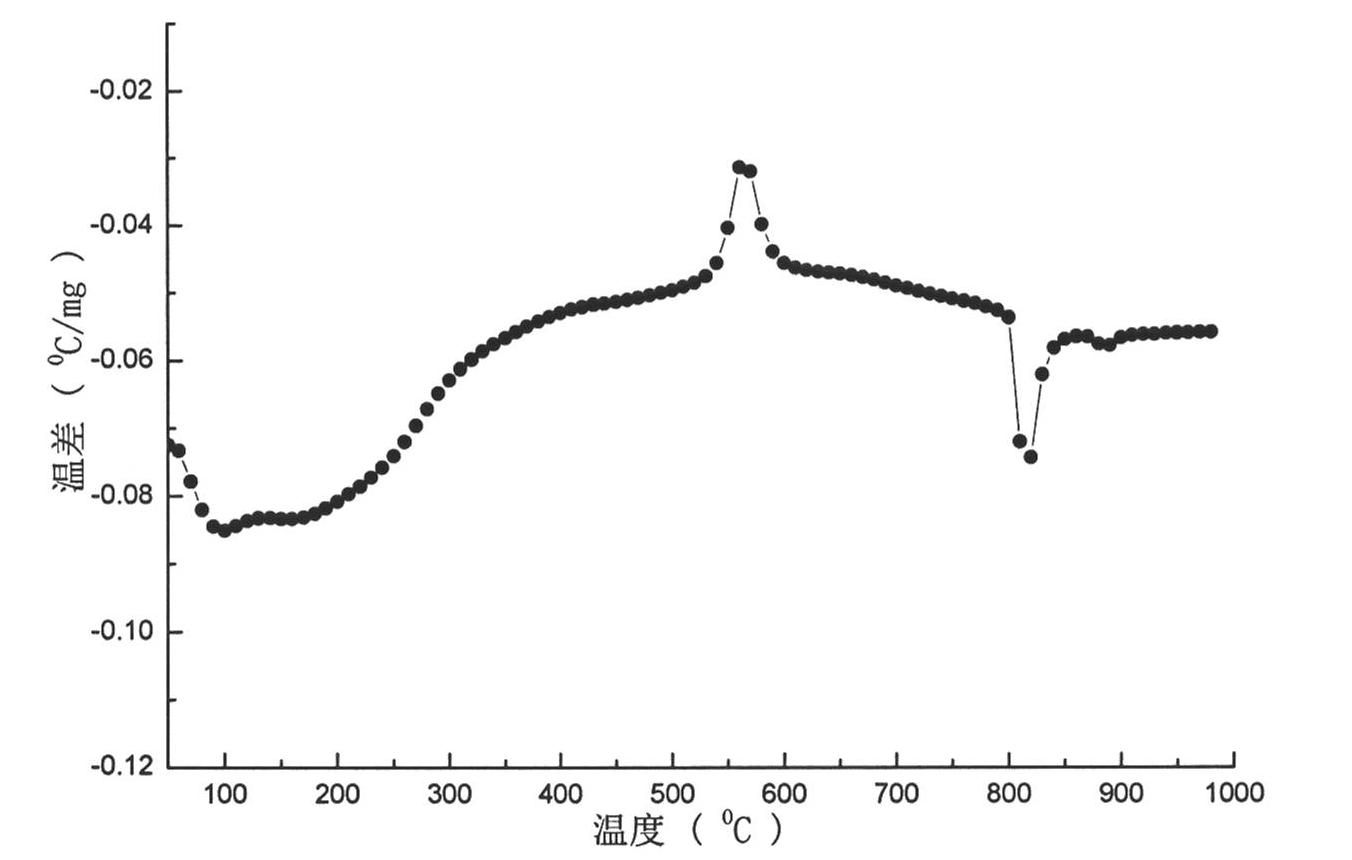

[0081] Figure 8 Mn for this example 52 al 46 (CNTs) ...

Embodiment 3

[0092] Except Mn in embodiment 2 52 al 46 (CNTs) 2 In the application method of type alloy, Mn is obtained by melting 52 al 46 (CNTs) 2 The alloy melt is changed to carry out rapid quenching of the melt under the cooling copper roller rotating at a peripheral speed of 30m / s, and the rest are the same as in Example 2, thus obtaining Mn 52 al 46 (CNTs) 2 Type alloy 30m / s quick-quenching alloy strip magnet and corresponding annealed Mn 52 al 46 (CNTs) 2 type alloy thin strip magnets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inner diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com