Method for preparing GaN substrate with porous surface and GaN substrate prepared by using the method

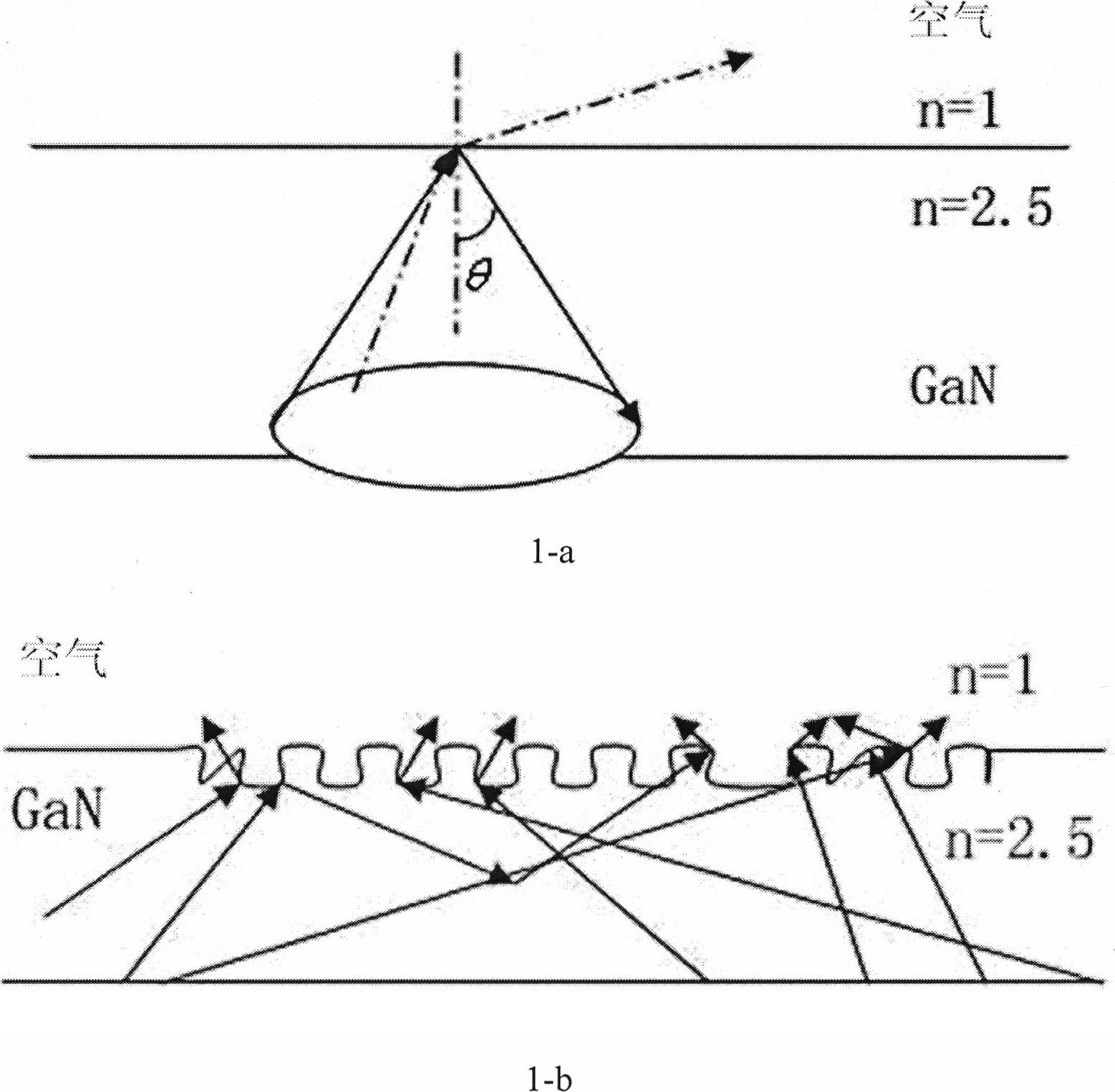

A technology with a porous surface and a substrate, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of not obtaining a porous structure, not proposing a process, and being simple, so as to improve the efficiency of light extraction and reduce the total reflection of the interface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The structure of the selected GaN substrate is as follows: a 30nm GaN low-temperature buffer layer is grown on the sapphire substrate material, and then an unintentionally doped n-type GaN layer is grown on the buffer layer with a thickness of 2.5 microns.

[0036] The preparation method of the porous GaN substrate comprises the following steps:

[0037] a. Clean the surface of the GaN substrate with acetone and alcohol respectively, put it in dilute hydrochloric acid and heat it to 40-70°C for 5-20 minutes, then wash it with deionized water, and wash it with N 2 Blow dry the surface. Then use electron beam evaporation technology to coat a layer of aluminum film with a thickness of 50-5000nm on the GaN layer on the surface of the GaN substrate;

[0038] b. place the GaN substrate covered with aluminum film on the surface in the acid solution (0.3M / L oxalic acid and 10% phosphoric acid mixed with a volume ratio of 1:1) in the electrochemical cell, the GaN substrate cove...

Embodiment 2

[0046] Adopt and the structure of the GaN substrate that example 1 selects for use, the preparation method of described superficially porous GaN substrate comprises the following steps:

[0047] a. Clean the surface of the GaN substrate with acetone and alcohol respectively, put it in dilute hydrochloric acid and heat it to 40-70°C for 5-20 minutes, then wash it with deionized water, and wash it with N 2 Blow dry the surface. Then use electron beam evaporation technology to coat a layer of aluminum film with a thickness of 500nm on the GaN layer on the surface of the GaN substrate;

[0048] b. place the GaN substrate covered with aluminum film on the surface in the acid solution (0.1M / L oxalic acid and 5% sulfuric acid mixed with a volume ratio of 1:1) in the electrochemical cell, the GaN substrate covered with aluminum film on the surface is Anode, graphite or Pt as the cathode, apply voltage to 60V, until the current is reduced to 0.1mA, anodic oxidation is realized by elec...

Embodiment 3

[0053] Adopt and the structure of the GaN substrate that example 1 selects for use, the preparation method of described superficially porous GaN substrate comprises the following steps:

[0054] a. Clean the surface of the GaN substrate with acetone and alcohol respectively, put it in dilute hydrochloric acid and heat it to 40-70°C for 5-20 minutes, then wash it with deionized water, and wash it with N 2 Blow dry the surface. Then use electron beam evaporation technology to coat a layer of aluminum film with a thickness of 500nm on the GaN layer on the surface of the GaN substrate;

[0055] b. place the GaN substrate covered with aluminum film on the surface in the acid solution (0.5M / L oxalic acid and 5% phosphoric acid mixed with a volume ratio of 1:1) in the electrochemical cell, the GaN substrate covered with aluminum film on the surface is Anode, graphite or Pt as the cathode, apply voltage to 60V, until the current is reduced to 0.1mA, anodic oxidation is realized by el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com