Organic tobacco seedling culture method

A technology of organic and tobacco seedlings, applied in the direction of organic fertilizers, botany equipment and methods, fertilizers made from biological waste, etc., can solve the problem that tobacco seedlings cannot meet the requirements of organic tobacco leaf production, cannot absorb water and nutrients, and soluble salts High content of peat, to achieve the effect of reducing the amount of peat used, low cost, and less residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

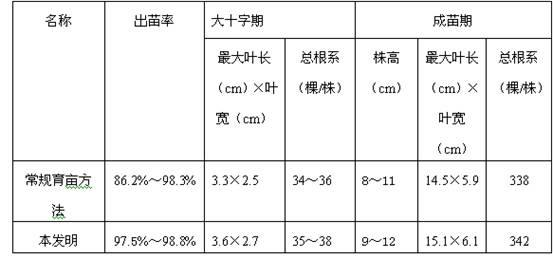

Examples

Embodiment 1

[0023] Example 1: Take 70 parts of vermicompost, 70 parts of biogas residue, and 30 parts of perlite according to the volume ratio, mix and stir evenly, and then put them in a wooden floating tray with 10 × 16 holes, fill them up and compact them, and sow two grains in each hole Put the flue-cured tobacco seeds into the nursery ponds filled with clean water, the volume is cubic centimeters, add biogas slurry to the nursery ponds 30 days, 40 days, and 50 days after sowing, and the amount of biogas slurry used is 5 kg / pan each time That's it.

Embodiment 2

[0024] Example 2: Take 30 parts of vermicompost, 30 parts of biogas residue, and 10 parts of perlite according to the volume ratio, mix and stir evenly, and then put them in a wooden floating tray with 10 × 16 holes, fill them up and compact them, and sow two grains in each hole Put the flue-cured tobacco seeds into the seedling pond filled with clean water. The portion is cubic centimeters. Add biogas slurry to the seedling pond on the first day after sowing.

Embodiment 3

[0025] Example 3: Take 80 parts of vermicompost, 80 parts of biogas residue, and 40 parts of perlite according to the volume ratio, mix and stir evenly, and put them in a wooden floating tray with 10 × 16 holes, fill them up and compact them, and sow two grains in each hole Put the flue-cured tobacco seeds into the seedling ponds filled with clean water, the portion is cubic centimeters, and add biogas slurry to the seedling ponds on the 1st day, 10th day, 20th day, 30th day, 40th day, 50th day, and 60th day after sowing , The amount of biogas slurry used can be calculated according to 10 kg / pan each time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com