Method for decoloring and degrading soluble azo dyes through catalysis of chloroperoxidase and oxidation of H2O2

A chloroperoxidase, azo dye technology, applied in chemical instruments and methods, oxidized water/sewage treatment, water/sewage treatment, etc., can solve the problem of low chromaticity removal rate, large fluctuation of treatment effect and inability to treat dyes and other problems, to achieve the effect of improving biodegradability, fast speed and simple operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

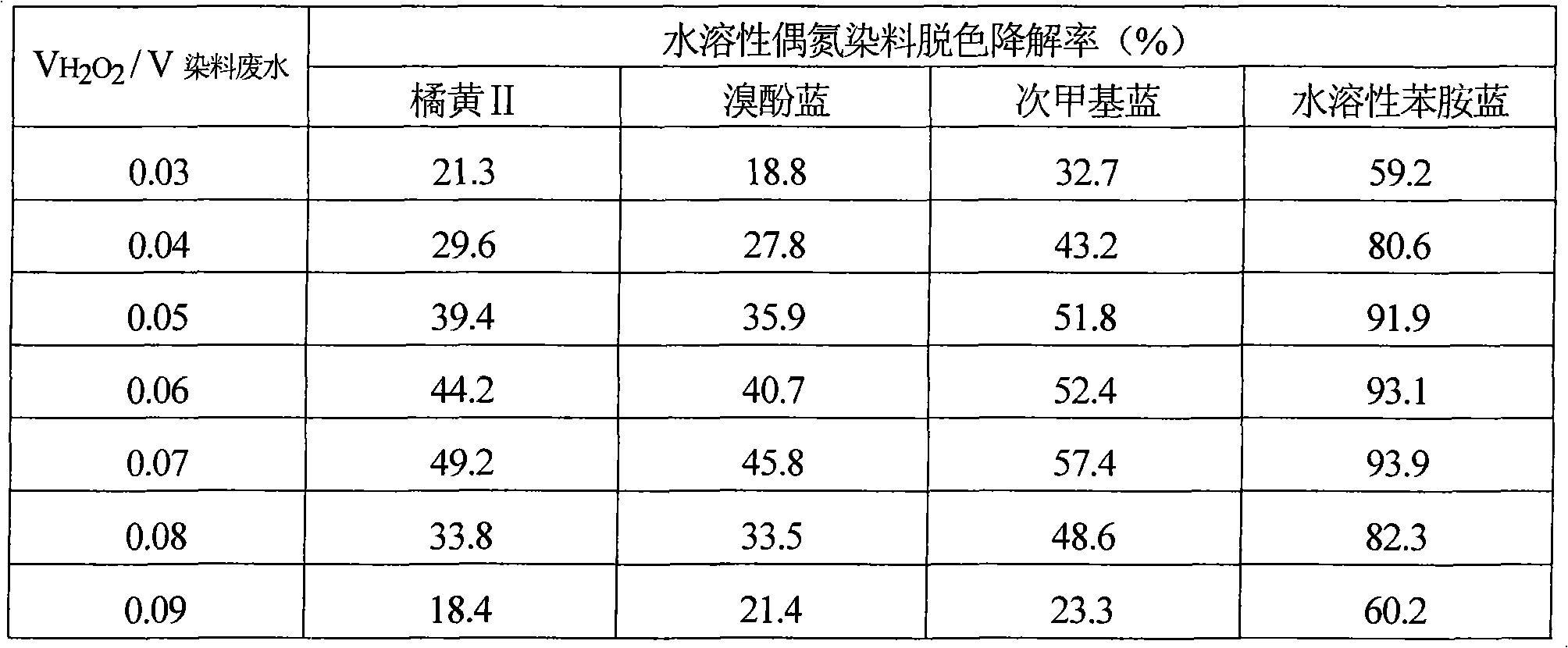

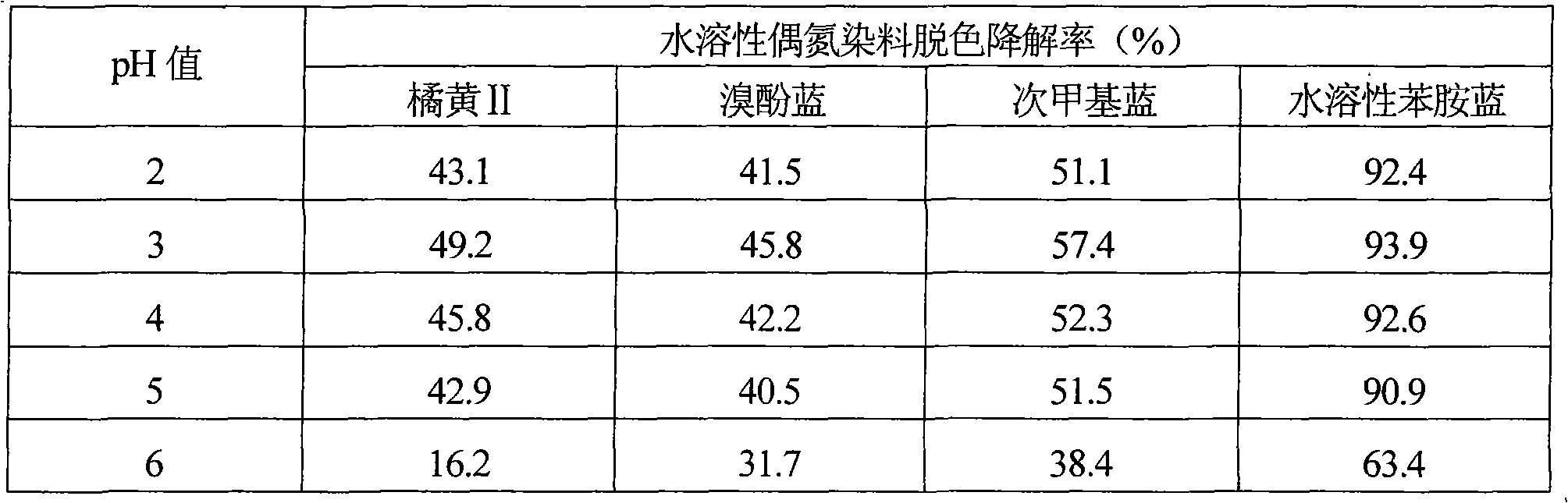

[0021] Taking the decolorization and degradation of 1000 mL of a water-soluble aniline blue solution with a concentration of 10 mmol / L as an example, the raw materials used and the decolorization and degradation methods are as follows:

[0022] 1. Prepare the solution

[0023] The amount and concentration of the formulated substance is 0.1mol / L KH 2 PO 4 -K 2 HPO 4 Buffer solution, adjust its pH to 5.5 with 3mol / L hydrochloric acid, use this buffer to prepare a chloroperoxidase solution with a substance concentration of 0.1mmol / L, and use 30% H 2 O 2 The solution and distilled water are prepared according to the conventional method. The concentration of the substance is 0.2mol / L H 2 O 2 Aqueous solution.

[0024] 2. Decolorization and degradation

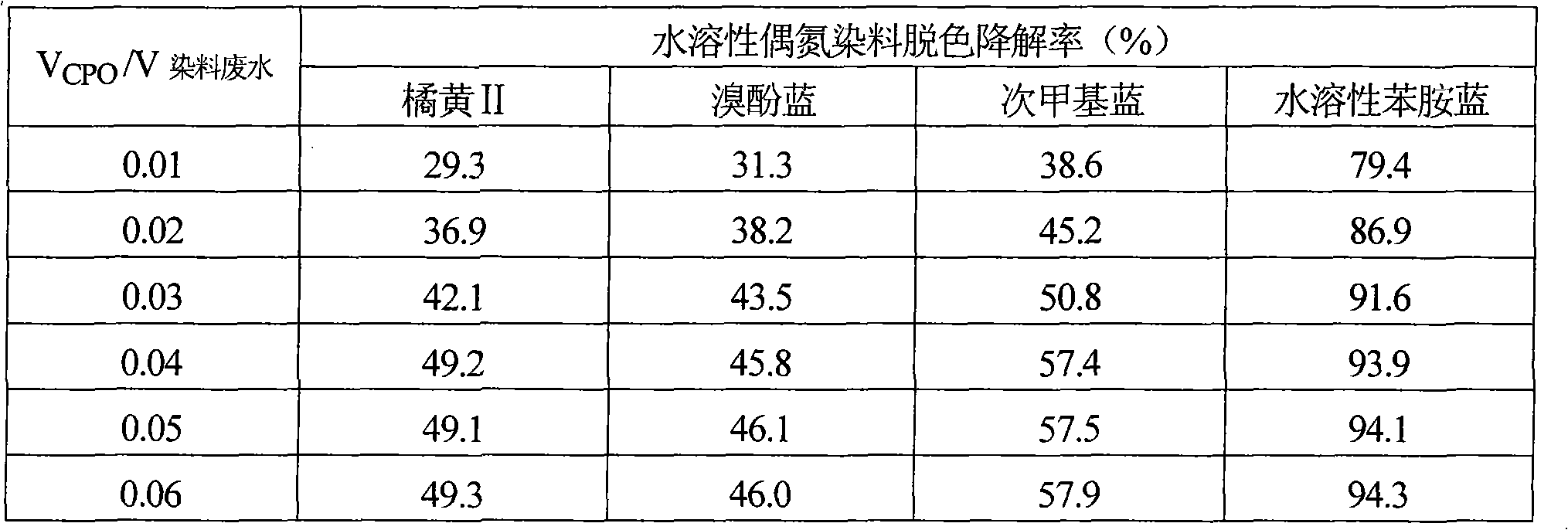

[0025] Add 40mL of chloroperoxidase solution with a substance concentration of 0.1mmol / L to 1000mL of a water-soluble aniline blue solution with a substance concentration of 10mmol / L, mix well, and a substance concentration of 10mmol / L water...

Embodiment 2

[0032] Taking the decolorization and degradation of 1000 mL of a water-soluble aniline blue solution with a concentration of 10 mmol / L as an example, the raw materials used and the decolorization and degradation methods are as follows:

[0033] In the decolorization and degradation step 2 of this embodiment, add 10 mL of a chloroperoxidase solution with a substance concentration of 0.1 mmol / L to 1000 mL of a water-soluble aniline blue solution with a substance concentration of 10 mmol / L, and mix well. The volume ratio of the water-soluble aniline blue solution with the substance concentration of 10mmol / L and the chloroperoxidase solution with the substance concentration of 0.1mmol / L is 1:0.01, and the substance concentration is 3mol / L H 2 SO 4 The amount of solution or substance is a NaOH solution with a concentration of 3mol / L to adjust the pH to 3, and 40mL of a substance with a concentration of 0.2mol / L is added. 2 O 2 Aqueous solution, water-soluble aniline blue solution with a...

Embodiment 3

[0035] Taking the decolorization and degradation of 1000 mL of a water-soluble aniline blue solution with a concentration of 10 mmol / L as an example, the raw materials used and the decolorization and degradation methods are as follows:

[0036] In the decolorization and degradation step 2 of this embodiment, add 60 mL of a chloroperoxidase solution with a substance concentration of 0.1 mmol / L to 1000 mL of a water-soluble aniline blue solution with a substance concentration of 10 mmol / L, and mix well. The volume ratio of the water-soluble aniline blue solution with the substance concentration of 10mmol / L and the chloroperoxidase solution with the substance concentration of 0.1mmol / L is 1:0.06, and the substance concentration is 3mol / L H 2 SO 4 The amount of the solution or substance is 3mol / L NaOH solution to adjust the pH to 3, add 80mL of the substance amount of H 0.2mol / L 2 O 2 Aqueous solution, water-soluble aniline blue solution with a substance concentration of 10mmol / L and H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com