Treatment method of waste papermaking water

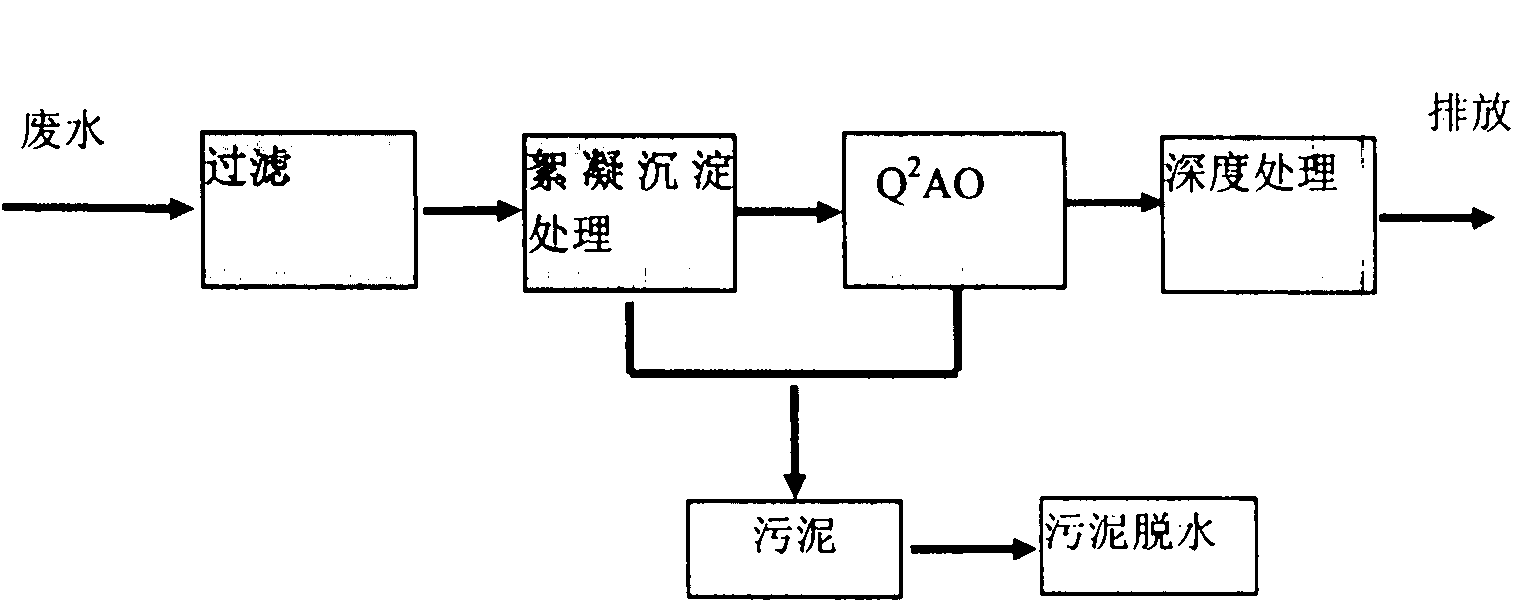

A treatment method and technology for papermaking wastewater, which are applied in the process of wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Pollution and other problems, to achieve the effect of improving biodegradability, simple process flow and short residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

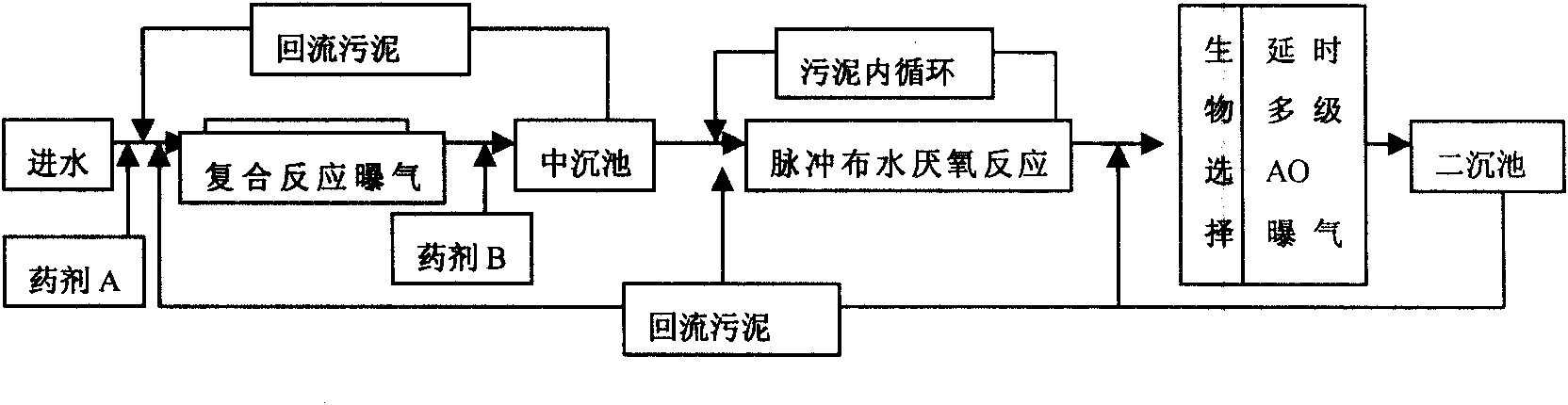

[0119] From July 15th to 22nd, 2008, due to the change of the pulping process, the COD of the raw water in the middle section was 5300mg / L, and the primary sedimentation water was 2530mg / L after being treated by the system, A 1 Effluent 1550mg / L, A 2 The effluent water is 900, and the effluent water of the secondary sedimentation tank is 80-105mg / L, SS<50mg / L.

Embodiment 2

[0121] From October 3rd to 10th, 2008, the COD of the raw water in the middle section was 3500mg / L, and the primary sedimentation water was 1800mg / L after being treated by the system, A 1 Effluent 1150mg / L, A 2 Effluent 705 Secondary sedimentation tank effluent 70-55mg / L, SS<50mg / L.

Embodiment 3

[0123] From July 10 to November 10, 2008, the average water level in the middle section was COD3800mg / L, and the initial precipitation water level after the system treatment was 1900mg / L, A 1 Effluent 1280mg / L, A 2 Effluent 730 Secondary sedimentation tank effluent 85mg / L, SS<50mg / L.

[0124]

[0125]

PUM

| Property | Measurement | Unit |

|---|---|---|

| sedimentation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com