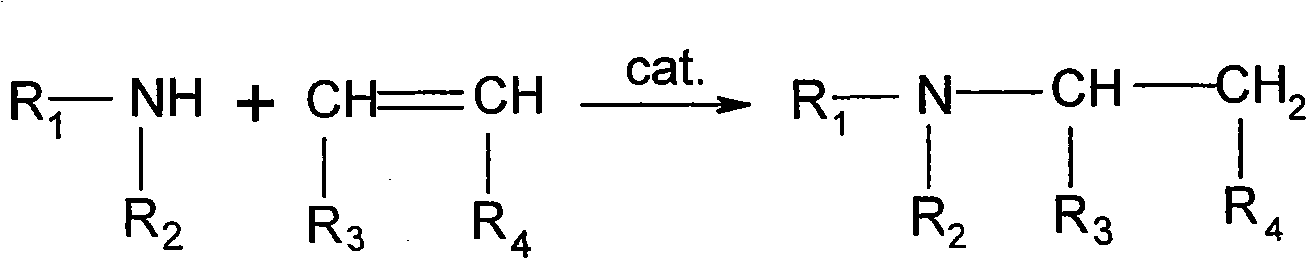

Method for catalytically synthesizing aminated compounds by using carbon-silicon solid acid as catalysts

A solid acid and catalyst technology, applied in the preparation of organic compounds, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of excess reagents, harsh reaction conditions, long reaction time, etc., to achieve short reaction time, mild reaction conditions, The effect of a small amount of catalyst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Conjugate Addition Reaction of Methyl Acrylate and Cyclohexylamine

[0026] The preparation of the first step carbon silicon solid acid

[0027] Add 6g P123, 180g 2M HCl and 45g H to a 500ml beaker 2 O, put it in a 40°C water bath and stir for 4 hours, then add 12.75g TEOS, continue to stir for 24 hours, put it into a reaction kettle with a polytetrafluoroethylene liner, crystallize in a 100°C oven for 24 hours, wash with water, filter with suction, and dry Dry it, and finally burn it in a muffle furnace at 550°C for 6 hours to obtain SBA-15 powder. Take 0.1g of oxalic acid, 15ml of absolute ethanol, 2.67g of furfuryl alcohol and 3.0g of SBA-15 and stir at room temperature for 4h, then put them in an oven at 80°C and an oven at 160°C for 6h each, 2 Burn at 500°C for 6h. Finally, use oleum to sulfonate at 120°C for 48 hours, wash with hot water, filter with suction, and dry to obtain functionalized carbon-silicon solid acid.

[0028] Step 2 Conjugate addition reactio...

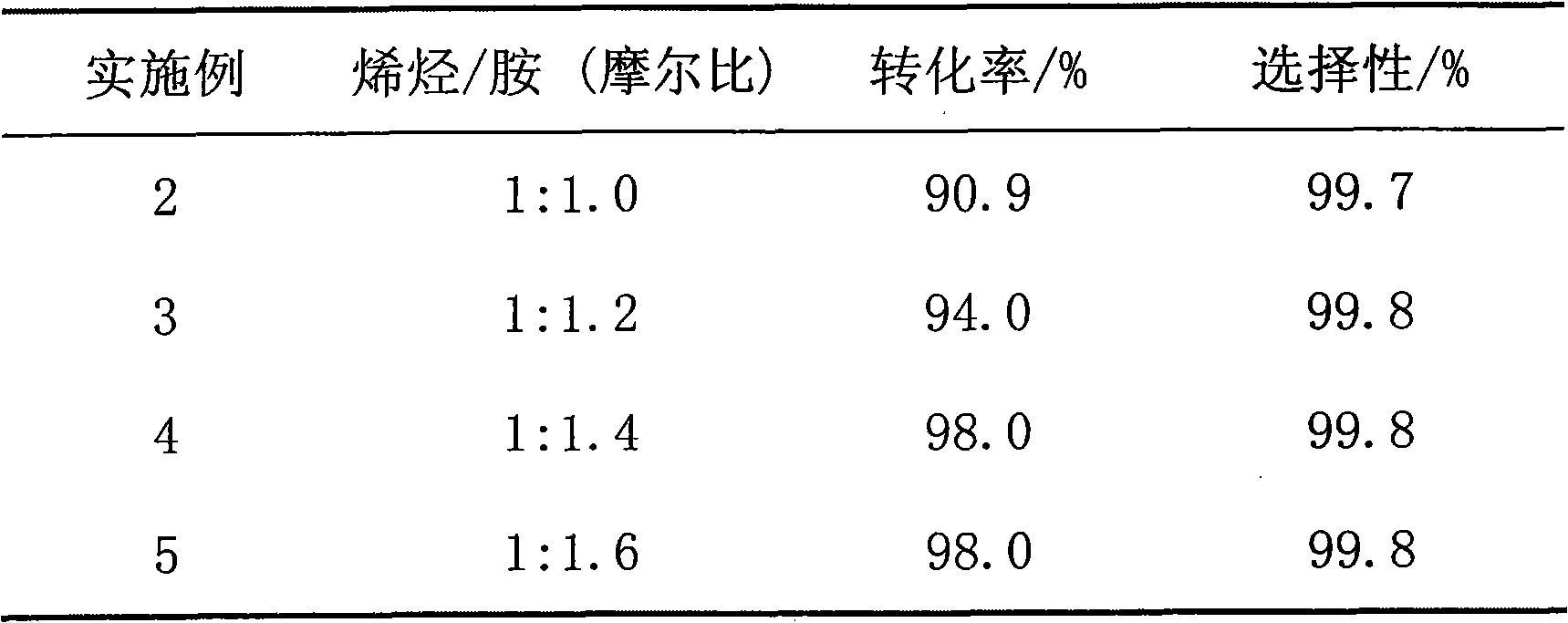

Embodiment 2~5

[0033] Except for the following differences, all the other are the same as in Example 1, the amount of catalyst is 0.04g, the amount of methyl acrylate is 0.02mol, the amount of cyclohexylamine is according to the ratio in Table 1, and the reaction is carried out for 10min.

[0034] Table 1

[0035]

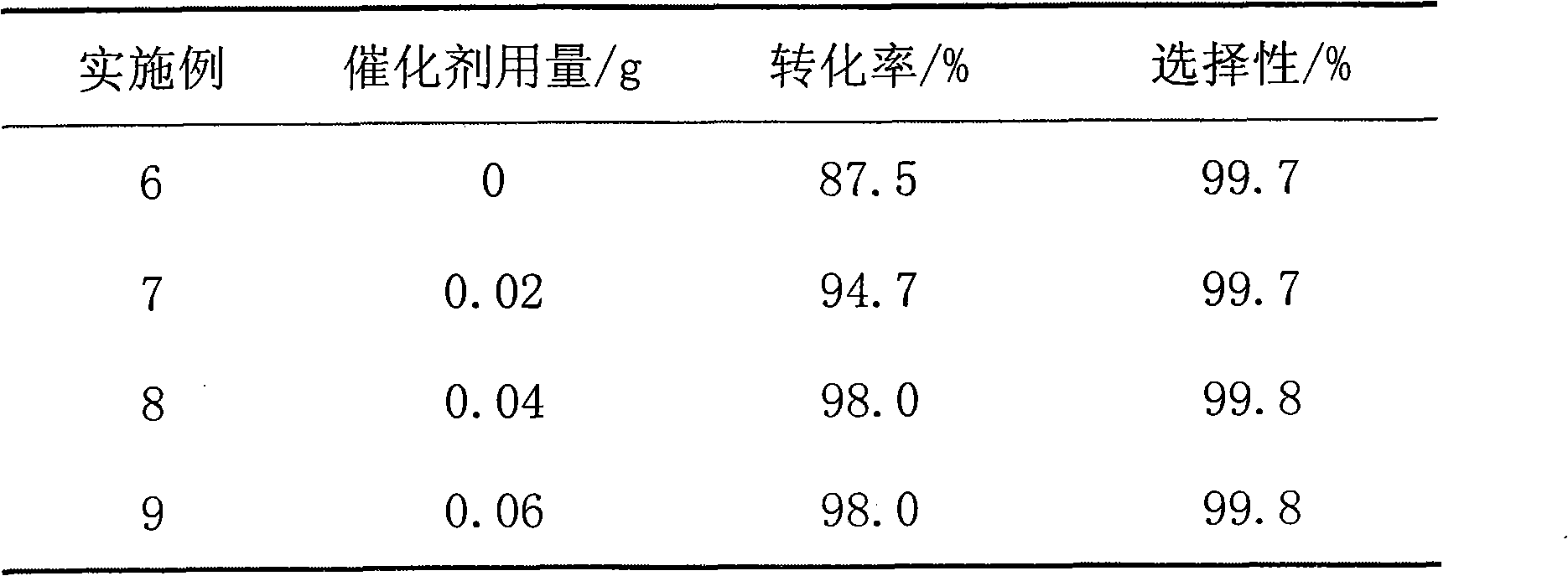

Embodiment 6~9

[0037] Except the following difference, all the other are the same as Example 1, methyl acrylate is 0.02mol, cyclohexylamine is 0.028mol, and solid acid catalyst is according to the consumption of Table 2 respectively, reacts 10min.

[0038] Table 2

[0039]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com