Method for refining J acid by using multi-functional integrated device

A technology of multifunctional equipment and integrated equipment, which is applied in the fields of organic chemical industry and dye technology, can solve the problems of a large number of equipment, low production efficiency, and high labor intensity, and achieve the effect of low manual operation intensity, high production efficiency, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below through specific embodiments and in conjunction with the accompanying drawings.

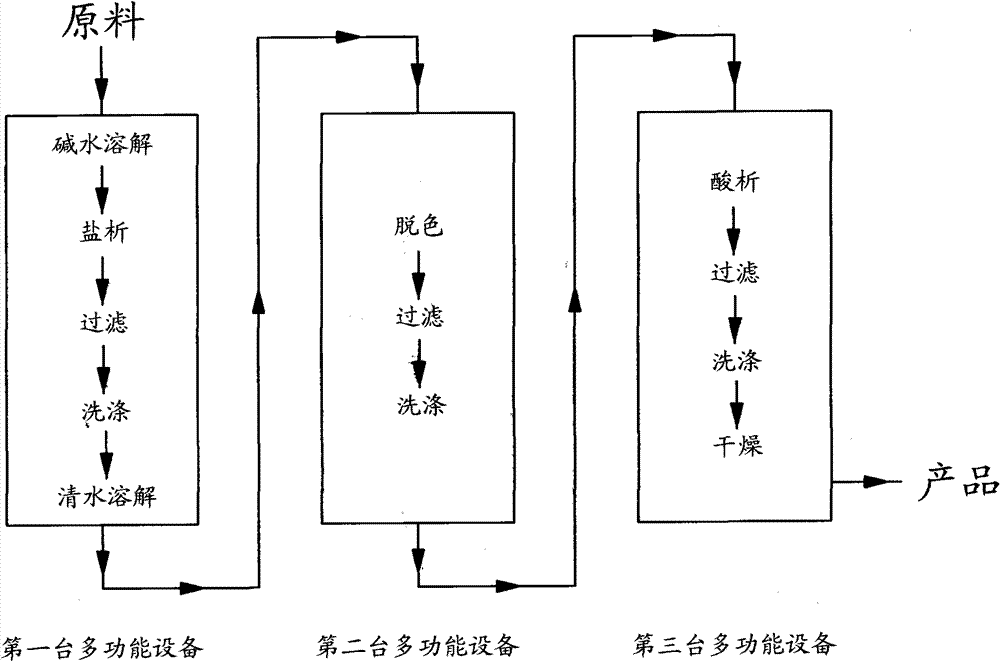

[0016] See attached figure 1 , the acid refining process is divided into the integrated process of alkaline water dissolution-salting-out-filtration-washing-clean water dissolution, the integrated process of decolorization-filtration-washing and the integrated process of acid analysis-filtration-washing-drying. The above-mentioned integration processes are completed in the multi-functional equipment integrating drying and drying. The multi-functional equipment should have the functions of stirring, temperature control, filtering, washing, drying, solid unloading, and liquid storage at the same time. The equipment material has anti-acid and alkali corrosion properties. .

[0017] Add water, sodium carbonate and medium acid to the first multifunctional equipment integrating filtration, washing and drying, raise the temperature to 80°C,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com