Harmless incineration disposal system and method for disposing domestic refuges

A technology for domestic waste and treatment methods, applied in combustion methods, incinerators, combustion types, etc., can solve problems such as difficult site selection, increased operating costs, secondary pollution of soil and water sources, and reduce toxic gases and harmful substances. , good social and economic benefits, and the effect of promoting and applying value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

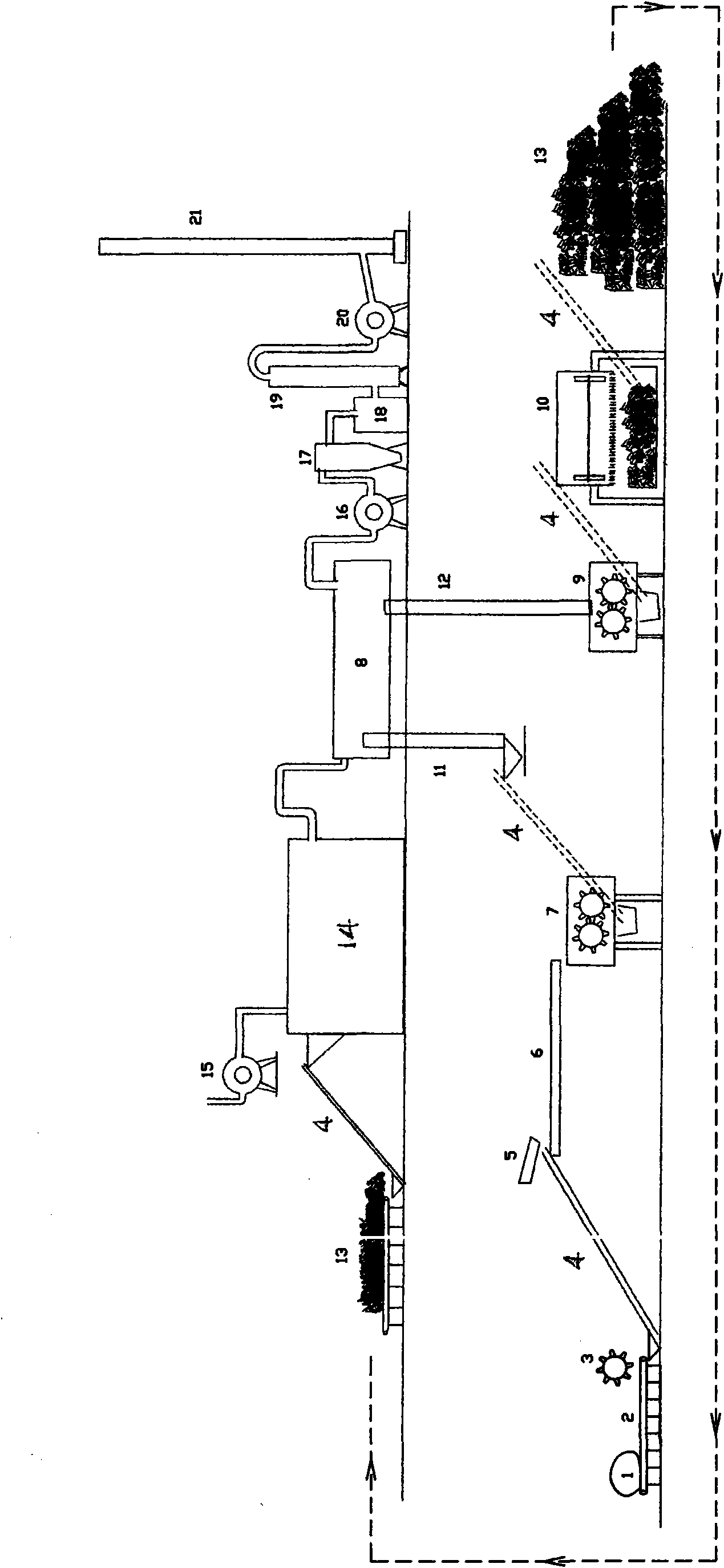

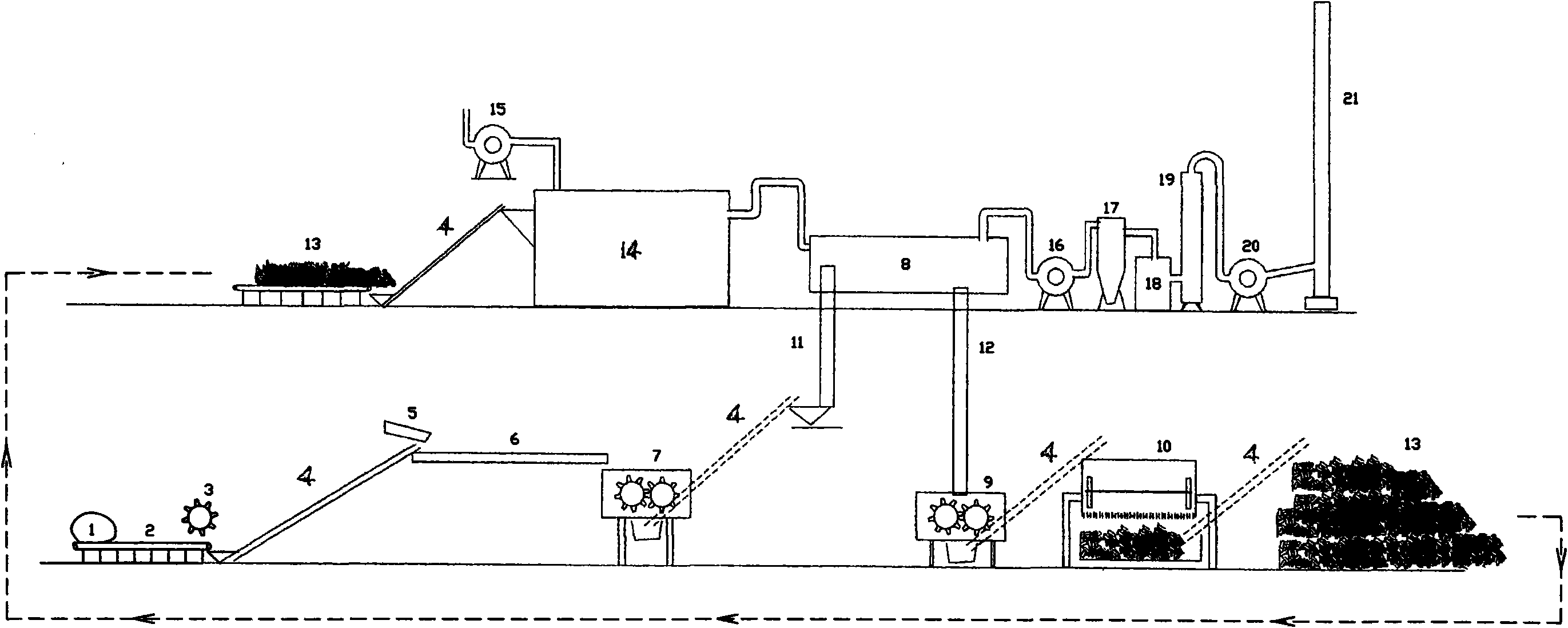

[0033]Referring to the accompanying drawings, the embodiment of the present invention is composed of a pre-production subsystem of domestic waste-derived fuel RDF, a drying and incineration subsystem, and a flue gas purification treatment subsystem. The production subsystem of the domestic waste-derived fuel RDF includes sequentially Bag breaking machine 3 connected by conveying mechanism, sorting mechanism, 5 tons / hour coarse crusher 7, 5 tons / hour drum dryer 8, 5 tons / hour fine crusher 9 and 5 tons / hour derived fuel RDF Forming machine 10, the drying and incineration subsystem includes an incinerator 14, a dryer 8 and corresponding flue gas pipes connected to each other, wherein the dryer 8 feed port is provided with the primary crusher 7 discharge port The feeder 11 that is connected, the discharge port of the dryer 8 is provided with the discharge machine 12 that is connected with the feed port of the fine crusher 9, and the described flue gas purification treatment subsyst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com