Method for preparing photoactive ternary amphiphilic polyester

An amphiphilic, photoactive technology, applied in the field of functional materials, to achieve excellent biocompatibility, thermal stability, and wide application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

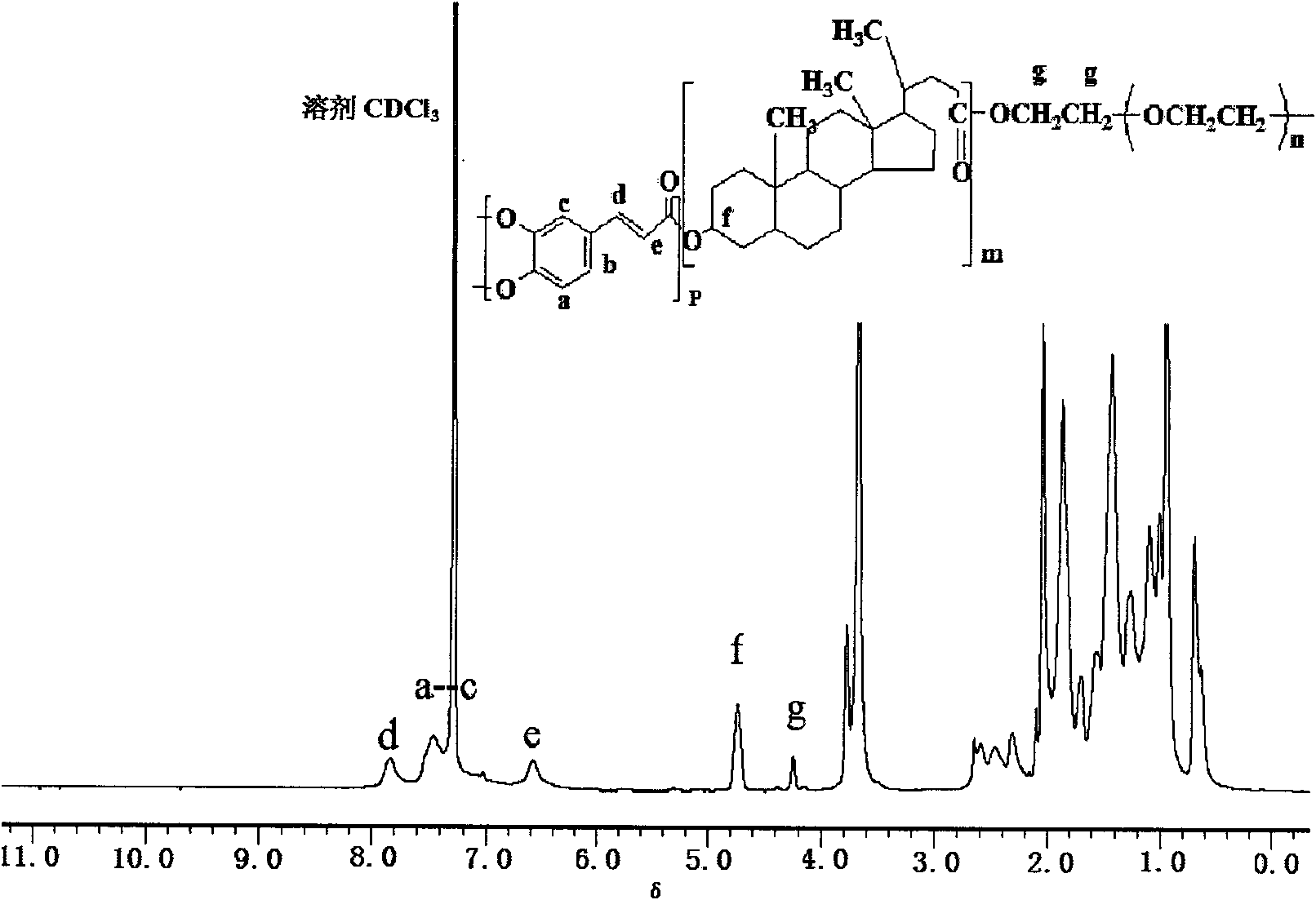

[0033] Weigh 3.76g (10mmol) of lithocholic acid, 1.80g (10mmol) of caffeic acid, 0.009g (0.1mmol) of anhydrous sodium acetate, and 35mL of acetic anhydride, add in a 250mL reactor, and heat up to After reacting for 2 hours at 140°C, 1.20 g (3 mmol) of PEG (400) was added dropwise, and finally the temperature was raised to 190-200° C., stirred and reacted at constant temperature for 6 hours. The whole reaction was carried out under nitrogen protection and light-proof conditions. Wash twice with deionized water, dissolve the product in chloroform and precipitate in ethanol after washing, repeat twice, and then dry at a constant temperature at 30°C to obtain a yellow product. The resulting copolymer is:

[0034]

[0035] Expressed as P(LCA-co-DHCA)-b-PEG.

Embodiment 2

[0037] Weigh 3.76g (10mmol) of lithocholic acid, 1.80g (10mmol) of caffeic acid, 0.045g (0.5mmol) of anhydrous sodium acetate, and 35mL of acetic anhydride, add in a 250mL reactor, and heat up to After reacting for 2 hours at 140°C, add 0.76g (10mmol) of 1,3-propanediol dropwise, gradually raise the temperature to 190-200°C, stir, and then react at constant temperature for 6h. The whole reaction is carried out under nitrogen protection and light-proof conditions. Wash twice with deionized water, dissolve the product in chloroform and precipitate in ethanol after washing, repeat twice, and then dry at a constant temperature at 30°C to obtain a yellow product. The resulting copolymer is:

[0038]

[0039] Expressed as P(LCA-co-DHCA-co-PDO).

Embodiment 3

[0041] Weigh 0.082g (0.2mmol) of cholic acid, 1.64g (10mmol) of coumaric acid, 0.018g (0.2mmol) of anhydrous sodium acetate, and 25mL of acetic anhydride, add them to a 250mL reactor, and heat up at a stirring speed of 200r / min After reacting for 1 hour at 160°C, add 0.80 g (2 mmol) of PEG (400) dropwise, gradually raise the temperature to 190-200° C., stir, and then react at constant temperature for 7 hours. The whole reaction is carried out under nitrogen protection and dark conditions. Wash twice with deionized water and twice with acetone, and then dry at a constant temperature at 30° C. to obtain a yellow product. The resulting copolymer is:

[0042]

[0043] Expressed as P(CA-co-4HCA)-b-PEG.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com