Tobacco processing active complex enzyme preparation for improving and enhancing tobacco quality and preparation method thereof

A compound enzyme preparation and tobacco technology, which is applied in the fields of tobacco, tobacco treatment, hydrolytic enzymes, etc., can solve the problems of complex enzymes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

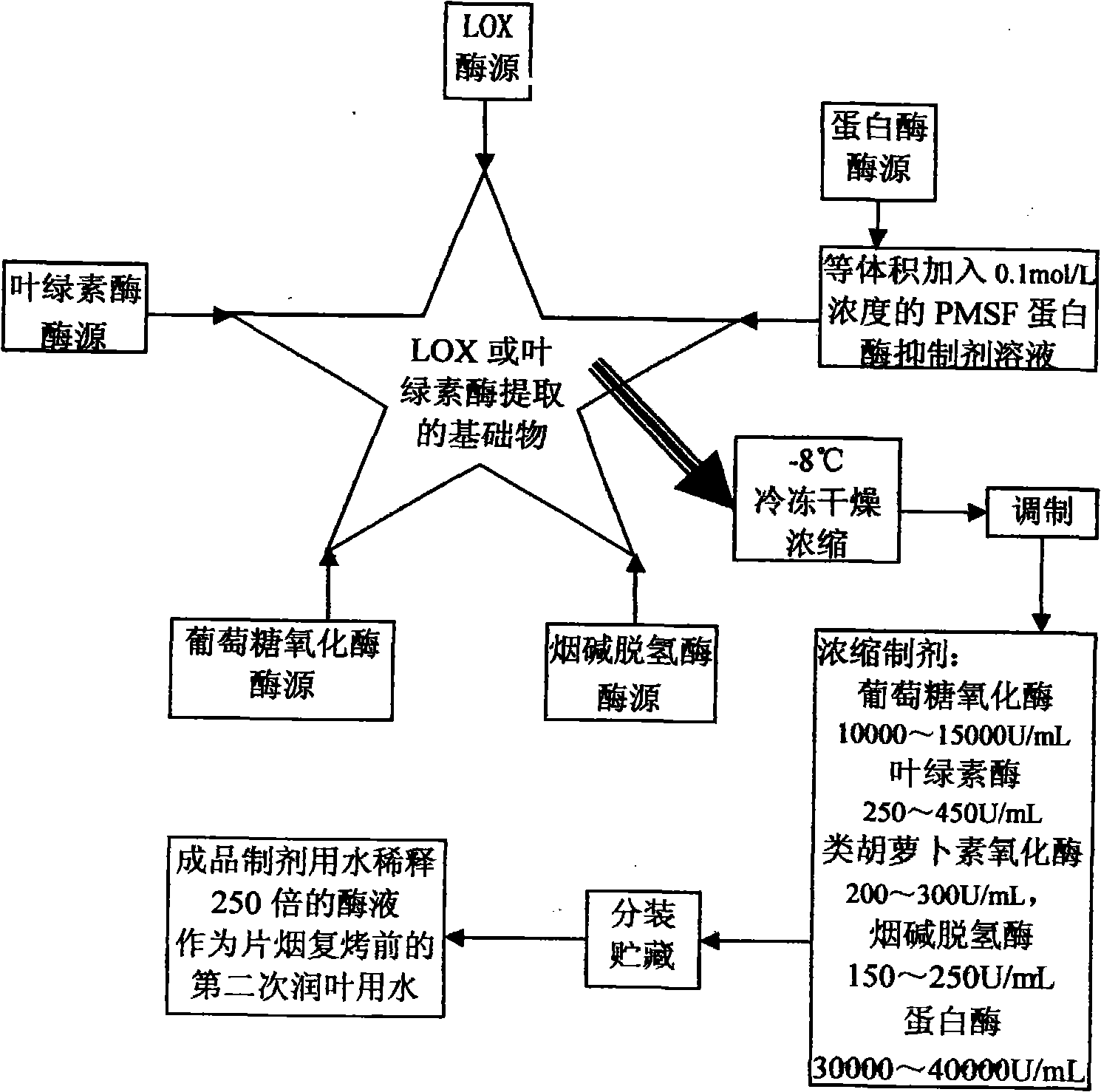

Image

Examples

Embodiment 1

[0110] Except for the 3-5 upper leaves of the tobacco plants, the apex leaves were taken as the raw material for extracting chlorophyllase, collected and stored in the shade for 3 days, and the chlorophyllase enzyme activity was sampled and tested. The combined enzyme activity was similar to that of the apex leaves; pH8. Dissolve the PMSF protease inhibitor in 0 buffer solution, add the top branch leaf when the concentration is 0.01mol / L, the ratio of the top branch leaf mass to the buffer solution containing PMSF volume is 1g: 4mL, break up the homogenate, filter, collect the filtrate, and let it stand 1h; Centrifuge the resting solution at 3500r / min for 20min, take the supernatant, add (NH 4 ) 2 SO 4 , so that the final concentration of ammonium sulfate is 25%, slowly stirring and dissolving, standing for 2h, and then adding (NH 4 ) 2 SO 4 Make the final concentration 80%, let it stand overnight, then centrifuge at 15000r / min at 4°C for 30min, take the supernatant, add 1...

Embodiment 2

[0115] When mixing the stock solution of chlorophyllase and carotenoid oxidase, the protease is added to the protease inhibitor solution with a concentration of 0.1 mol / L in equal volume in advance, and then mixed with other components. Other steps are the same as in Example 1.

Embodiment 3

[0117] Add the buffer solution containing PMSF to the filter residue of extracting chlorophyllase and carotenoid oxidase for the first time, the ratio of filter residue mass to buffer solution is 1g: 5mL, stir for 2h, filter and squeeze the residue, combine the filtrate with the previous filtrate, and let it stand 1h, centrifuge the standing solution at 3500r / min for 20min, take the supernatant, add (NH 4 ) 2 SO 4 Extract chlorophyllase and carotenoid oxidase. Other steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com