Outdoor double heat exchanger defrosting low-temperature heating system

A technology for outdoor heat exchangers and heating systems, which can be used in fluid heaters, heating and cooling combinations, refrigerators, etc., and can solve problems such as easy damage of heat pump compressors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

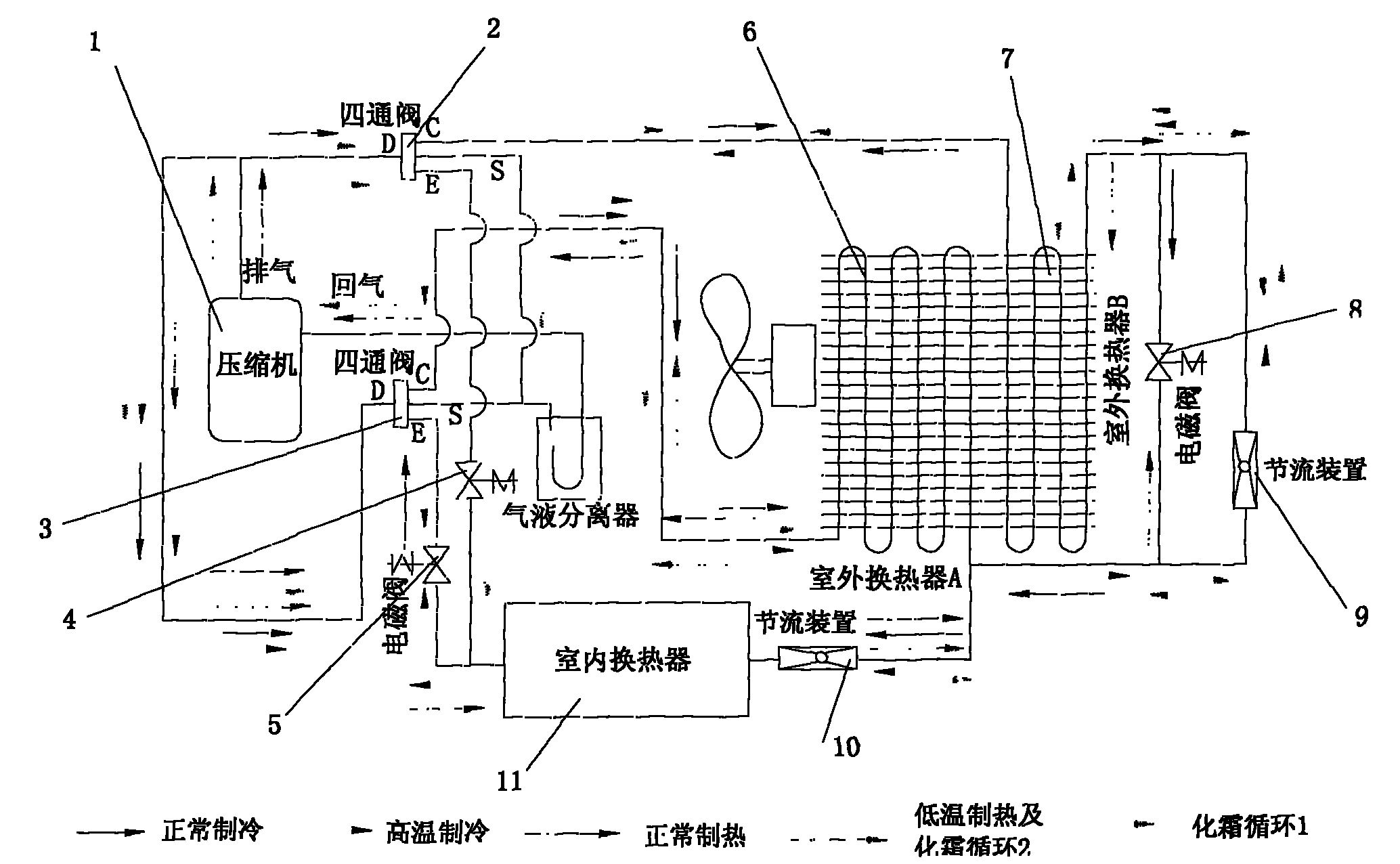

[0028] Embodiment 1 heat pump air conditioning system one

[0029] Such as figure 1The air conditioning system shown includes a compressor 1, a first four-way reversing valve 2, a second four-way reversing valve 3, a first outdoor heat exchanger 6, a second outdoor heat exchanger 7, and a first throttling device 9. The second throttling device 10, the indoor heat exchanger 11, the first solenoid valve 4 and the second solenoid valve 5, and the exhaust gas from the compressor 1 flow to the first four-way reversing valve 2 and the second four-way reversing valve respectively The D end of the valve 3; one end of the first outdoor heat exchanger 6 and one end of the second outdoor heat exchanger 7 are respectively connected to the common inlet and outlet pipes at both ends of the first throttling device 9 and the third electromagnetic valve 8; the first outdoor heat exchanger The other ends of the device 6 and the second outdoor heat exchanger 7 are respectively connected to the ...

Embodiment 2

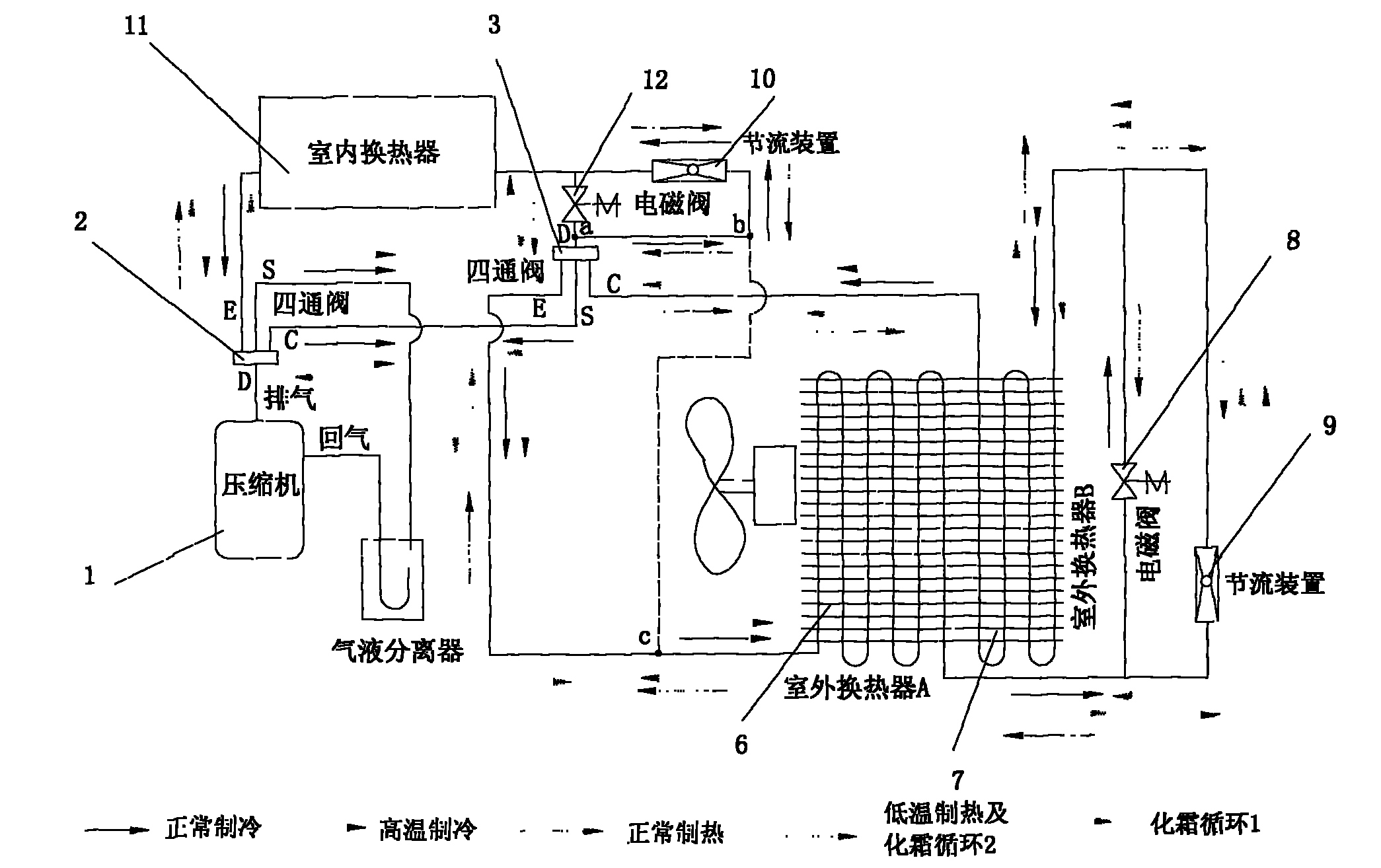

[0040] Embodiment 2 heat pump air conditioning system two

[0041] Such as figure 2 In the air conditioning system shown, the exhaust pipe of compressor 1 is connected to the D end of the first four-way valve reversing valve 2, and the gas pipe E at one end of the first four-way valve reversing valve 2 is connected to the indoor heat exchanger 11, and the other One end of the air pipe C is connected to the S end of the second four-way reversing valve 3; the air pipes E and C at both ends of the second four-way reversing valve 3 are respectively connected to the first outdoor heat exchanger 6 and the second outdoor heat exchanger 7; There is a second throttling device 10 and a fourth solenoid valve 12 between the D end of the second four-way reversing valve 3 and the liquid pipe of the indoor heat exchanger 11, and the fourth solenoid valve 12 and the second throttling device 10 are connected in parallel ; When the second throttling device 10 is an electronic expansion valve,...

Embodiment 3

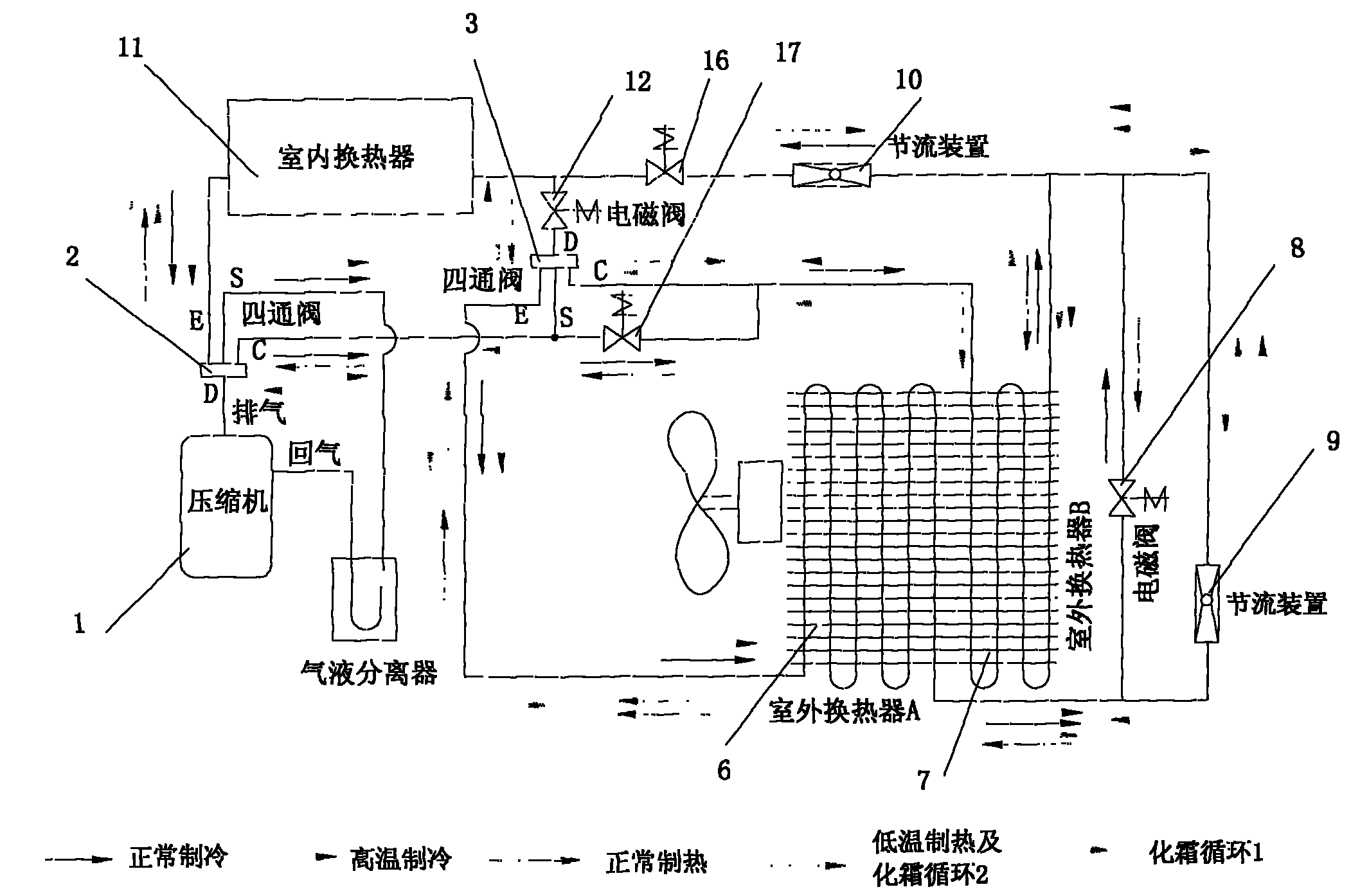

[0052] Embodiment 3 heat pump air conditioning system three

[0053] Such as image 3 In the air conditioning system shown, the exhaust pipe of compressor 1 is connected to the D end of the first four-way valve reversing valve 2, and the gas pipe E at one end of the first four-way valve reversing valve 2 is connected to the indoor heat exchanger 11, and the other The air pipe C at one end is connected to the S end of the second four-way reversing valve 3; the air pipes E and C at the other two ends of the second four-way reversing valve 3 are respectively connected to the first outdoor heat exchanger 6 and the second outdoor heat exchanger 7 There is a fourth electromagnetic valve 12 between the D end of the second four-way reversing valve 3 and the liquid pipe of the indoor heat exchanger 11; the S end of the second four-way reversing valve 3 and any end air pipe E or C pass through The fifth solenoid valve 17 is connected together; one end of the second throttling device 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com