Pixel structure of CMOS (Complementary Metal-Oxide-Semiconductor Transistor) image sensor and manufacture method thereof

An image sensor and pixel structure technology, which is applied in radiation control devices and other directions, can solve problems such as complex process, leakage current, and low ion implantation energy, and achieve uniform ion distribution, solve afterimage problems, and good control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

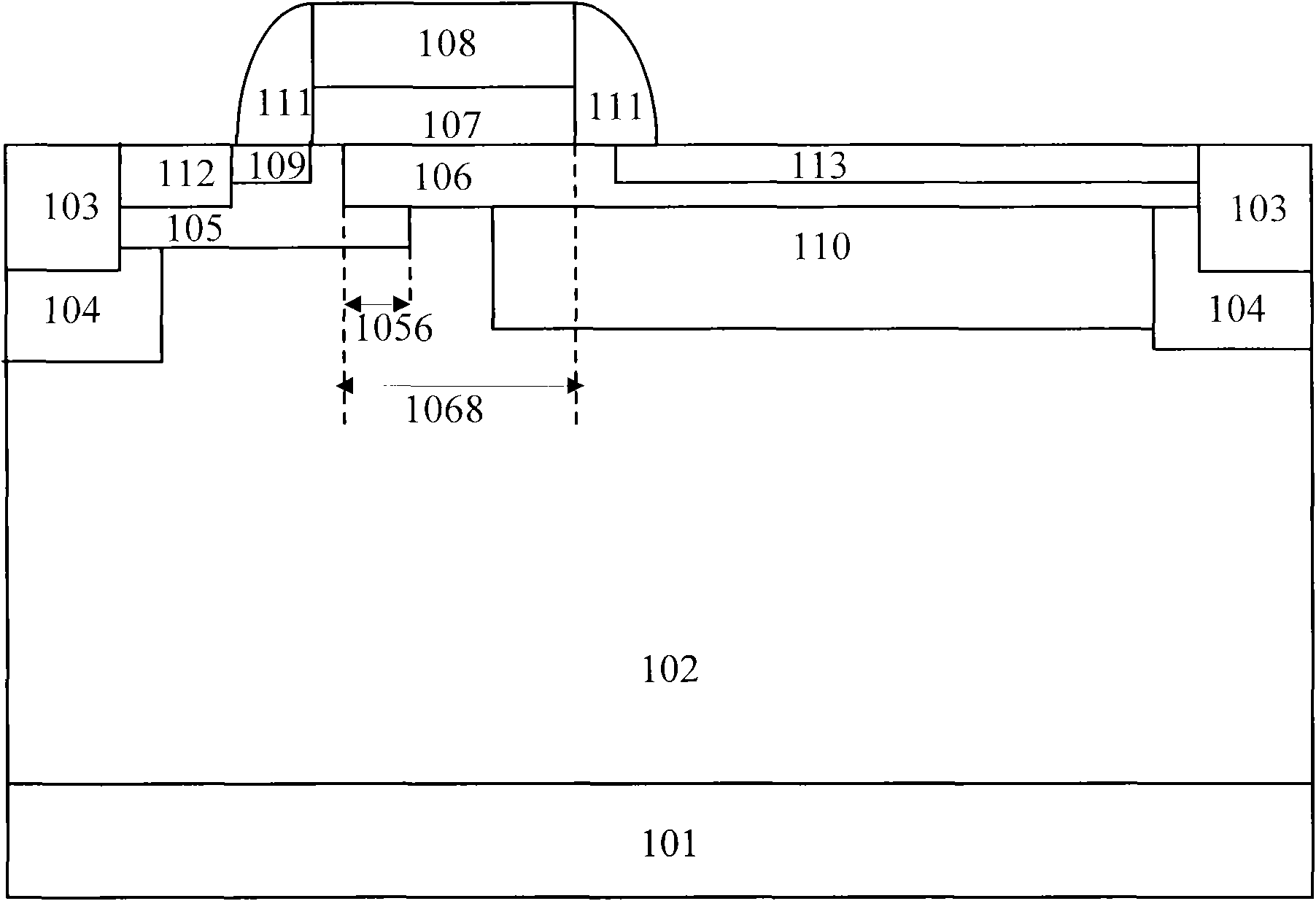

[0046] The inventors have found that the thickness of the threshold voltage adjustment region of the CMOS image sensor in the prior art is difficult to control, and is not suitable for the sub-micron level manufacturing process; There is a risk of leakage current; the isolation structure and isolation well are used to isolate the photodiode and MOS transistor at the same time, and the process is complicated.

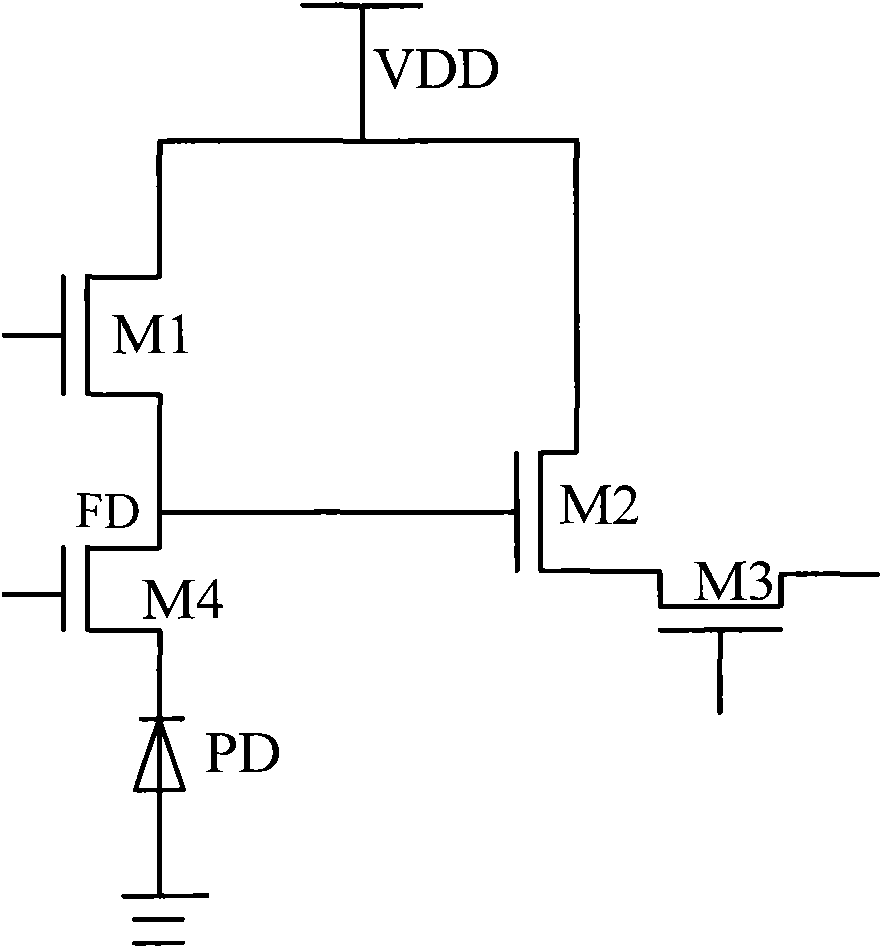

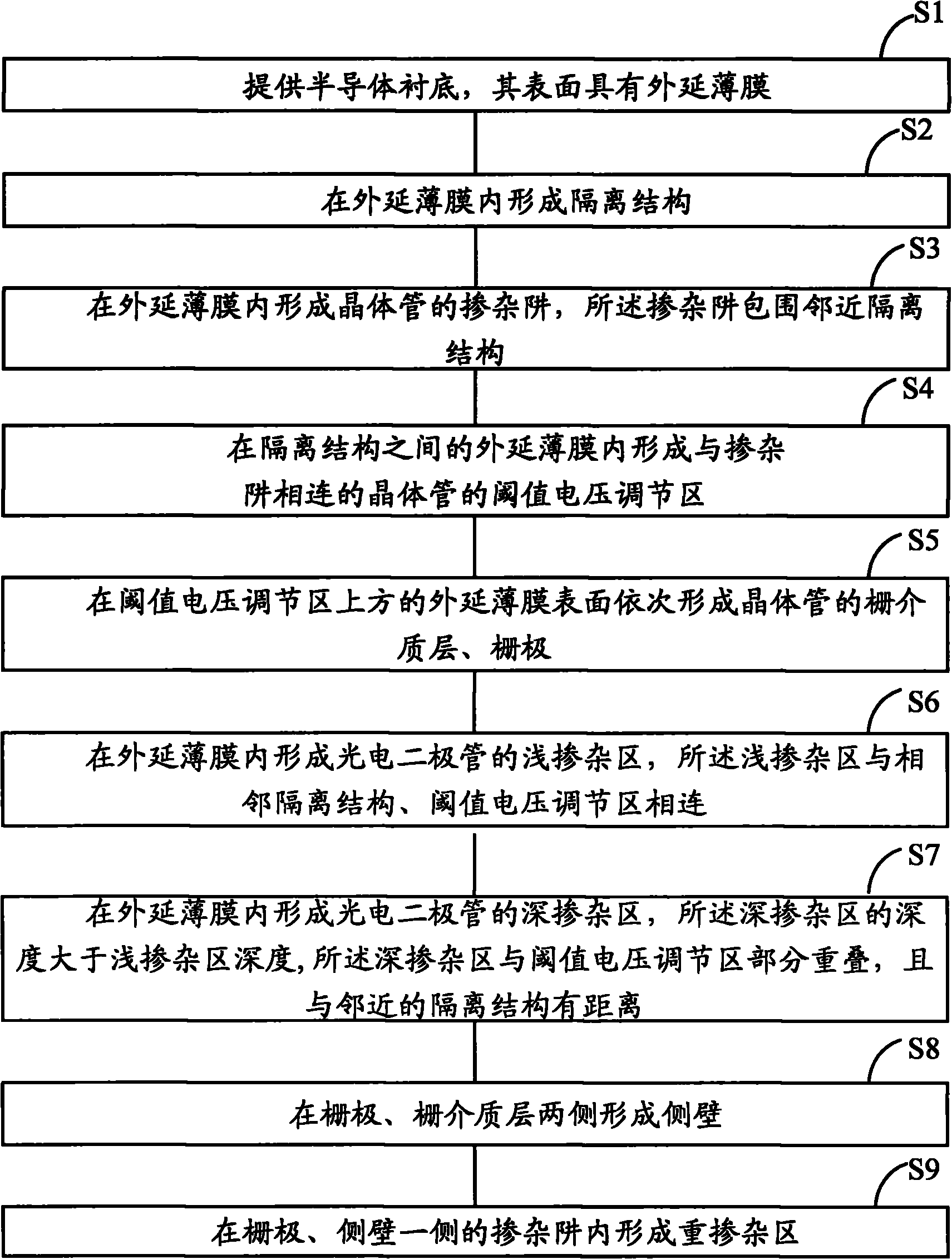

[0047] Therefore, the inventor provides a pixel structure of a CMOS image sensor, the structure is as follows:

[0048] a semiconductor substrate, an epitaxial film on the substrate, an isolation structure in the epitaxial film, a MOS transistor in the epitaxial film between the isolation structures, and a photodiode adjacent to the MOS transistor, the The MOS transistor includes: a gate dielectric layer and a gate sequentially located on the surface of the epitaxial film, and side walls located on both sides of the gate dielectric layer and the gate;

[0049] a doped w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com