Installation structure of optical fiber sensor used for contact temperature detection of power switch cabinet

A fiber optic sensor and fiber optic sensing technology, which is applied in substation/switch layout details, thermometers, measuring devices, etc., can solve the shortcomings of being susceptible to electromagnetic interference and other problems, and achieve the effects of being less susceptible to electromagnetic interference, easy to system integration, and small in size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

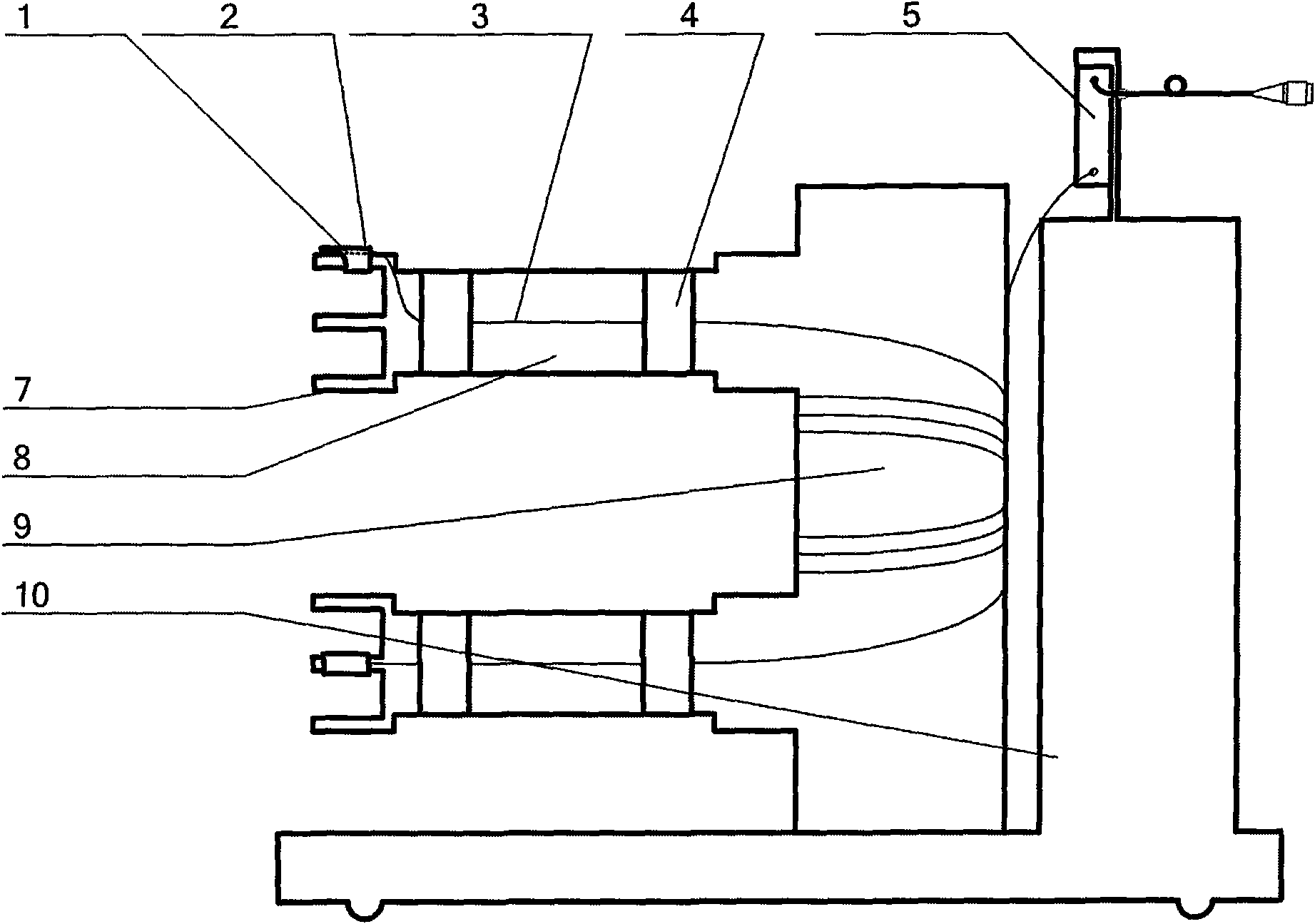

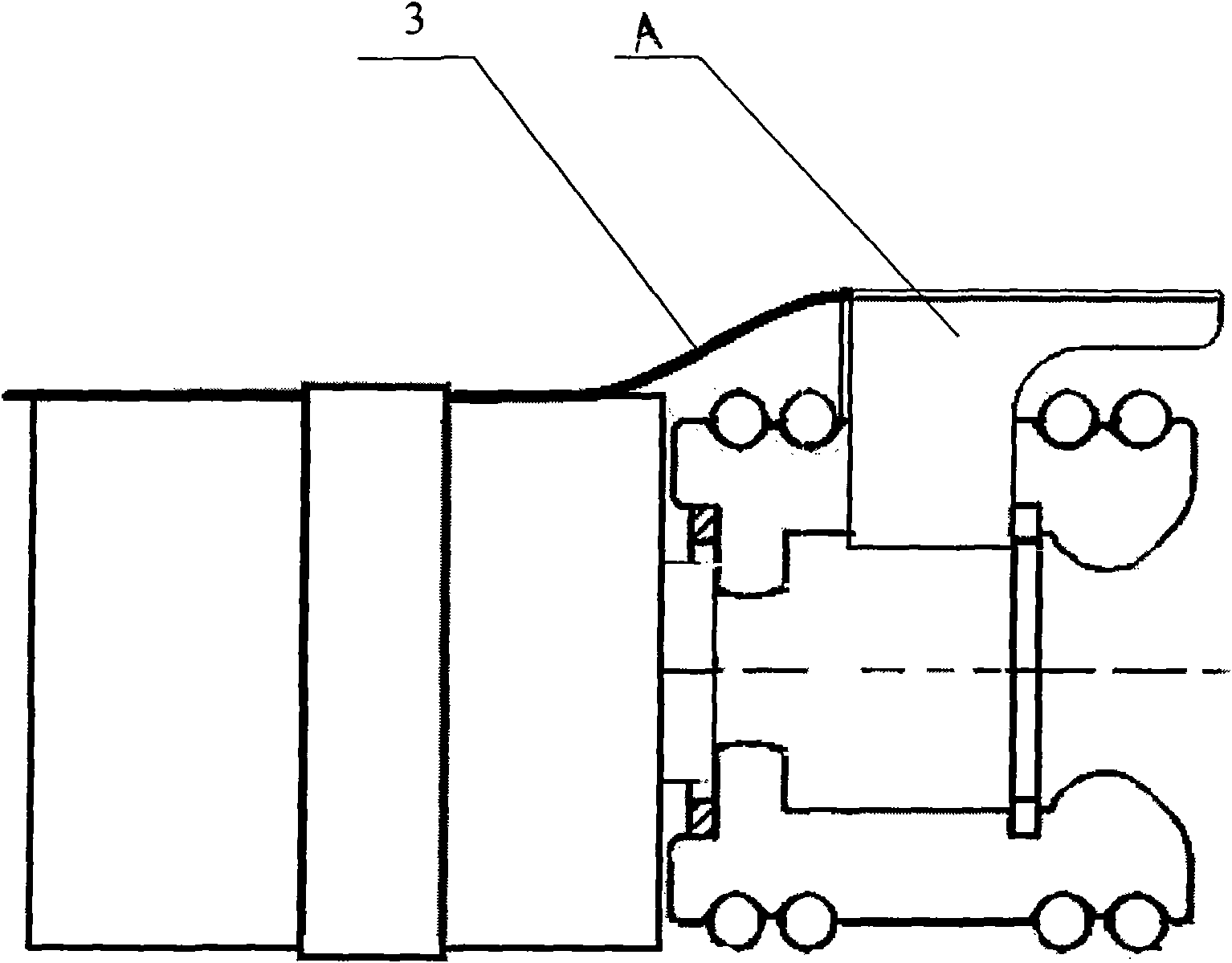

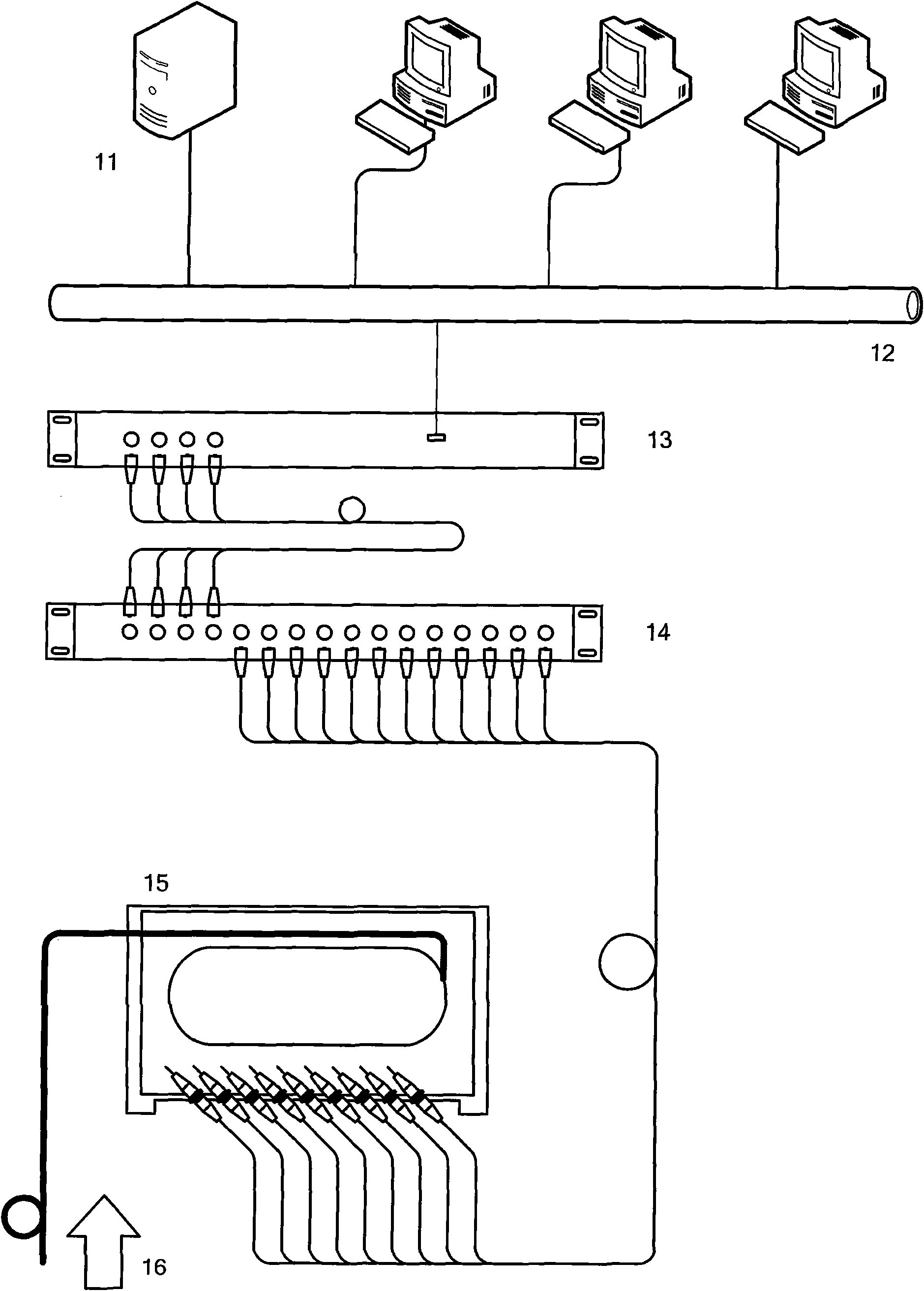

[0010] Control attached figure 1 , its structure includes sensor 1, optical fiber sensing fixture 2, sheathed optical fiber 3, heat shrinkable sleeve 4, terminal distributor 5, industrial optical fiber connector 6, circuit breaker contact 7, circuit breaker arm 8, circuit breaker A breaker column 9, a circuit breaker controller 10, wherein the sensor 1 is equipped with an optical fiber sensing fixture 2, the circuit breaker contact 7 is connected to a sheathed optical fiber 3, and a heat shrinkable sleeve 4 is provided between the circuit breaker arm 8 and the circuit breaker column 9 , the circuit breaker column 9 is connected to one terminal of the terminal distributor 5, the other terminal of the terminal distributor 5 is connected to the industrial optical fiber connector 6, and the terminal distributor 5 is connected to the circuit breaker controller 10. When working, the The optical signal representing the temperature is sent out through the optical fiber, splitter and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com