Visible light catalyst BiVO4 and preparation method thereof

A catalyst, visible light technology, applied in the field of preparation of a new three-dimensional connected pore structure visible light catalyst BiVO4, can solve the problems of coarse bismuth vanadate particles, poor photocatalytic performance, small specific surface area, etc., to reduce synthesis cost, large specific surface area, small particle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

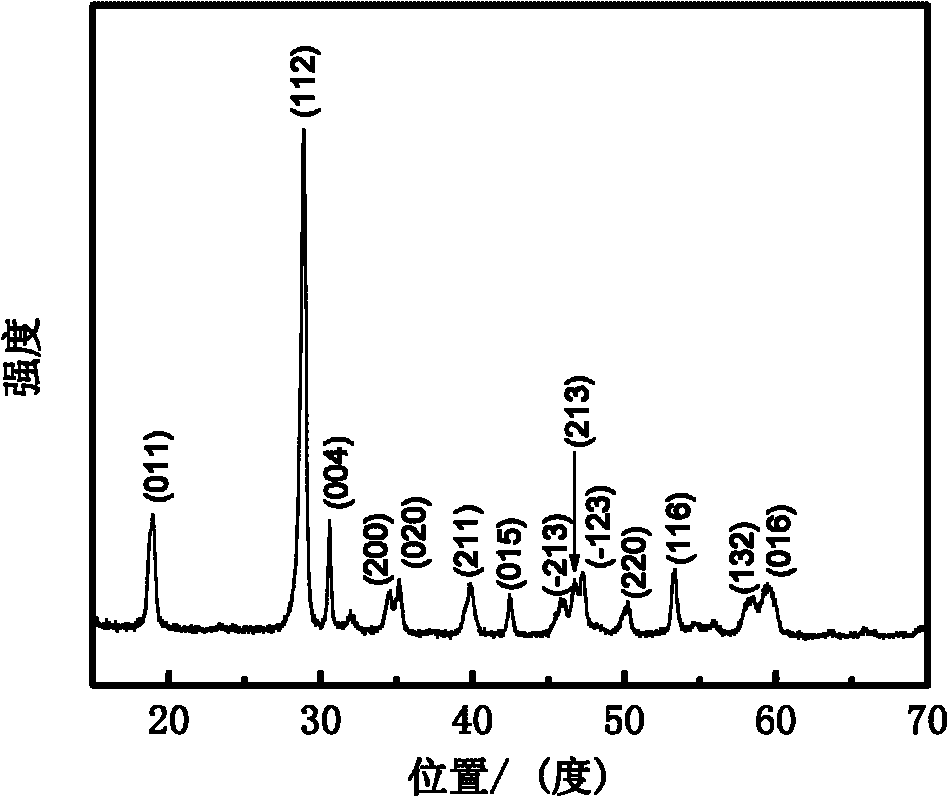

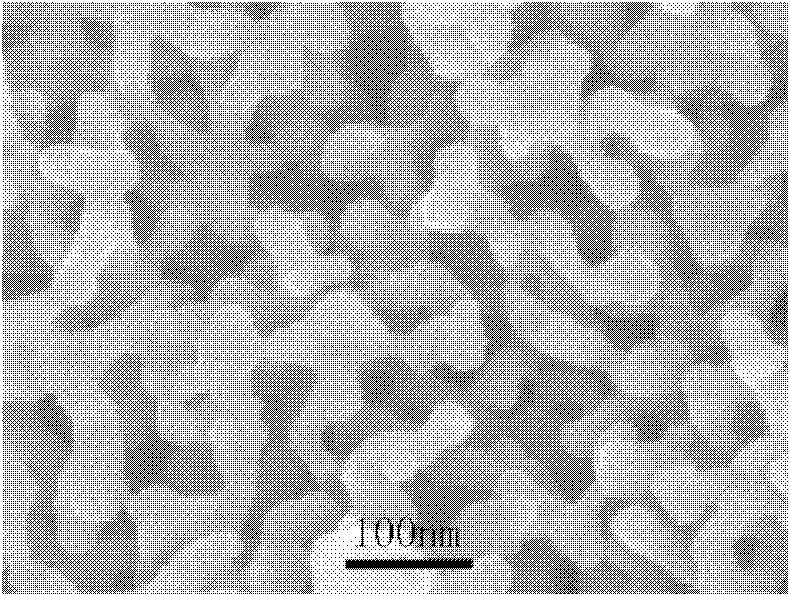

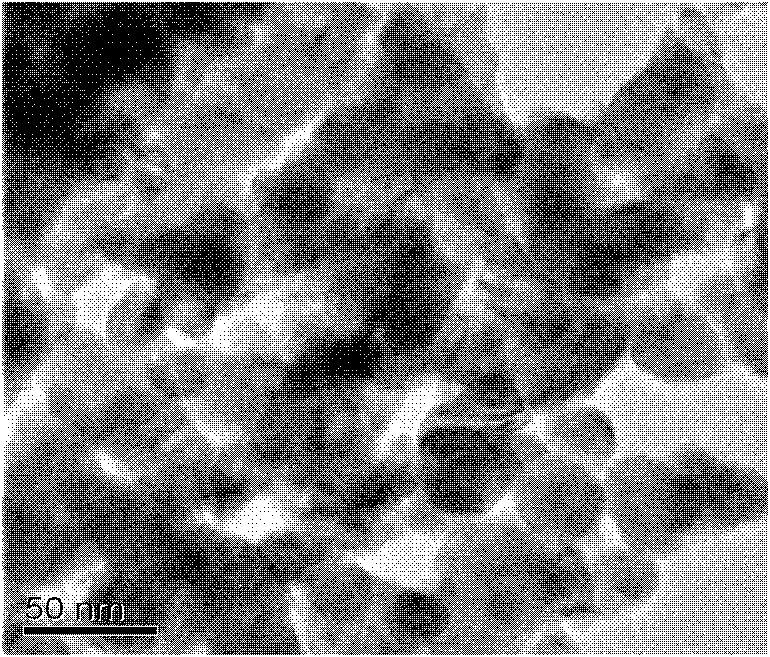

[0023] 2.4255g bismuth nitrate pentahydrate (Bi(NO 3 ) 3 ·5H 2 O) dissolved in 100ml ethylene glycol (EG) to prepare Bi ion concentration of 0.05mol L -1 After the solution, add 0.5849g ammonium metavanadate (NH 4 VO 3 ), ultrasonically oscillated for 20 min, and stirred thoroughly to dissolve completely. After the solution was clear and transparent, it was transferred to a constant temperature water bath and kept at 60°C for 7 days to obtain a flocculent precipitate. Remove the EG supernatant, add distilled water to wash, and centrifuge. After repeating this five times, wash with alcohol and centrifuge twice, and dry the obtained precipitate in an oven. The dried material was calcined at 400 °C for 2.5 h to obtain a three-dimensional connected pore structure visible photocatalyst BiVO 4 . After XRD analysis ( figure 1 ), the main phase of the material is bismuth vanadate with monoclinic scheelite structure, corresponding to the standard card JCPD fileNo.01-075-1866. ...

example 2

[0026] 5.7916g bismuth acetate pentahydrate (Bi(CH 3 COO) 3 ·5H 2 O) dissolved in 150ml ethylene glycol (EG) to form a Bi ion concentration of 0.1mol L -1 After the solution, according to Bi:V=1:1.5, add 2.6320g ammonium metavanadate (NH 4 VO 3 ), ultrasonically oscillate for 20 min, and stir well to dissolve it. After the solution was clear and transparent, it was transferred to a constant temperature water bath and kept at 90°C for 2 days to obtain a flocculent precipitate. Remove the EG supernatant, add distilled water to wash, and centrifuge. After repeating this five times, wash with alcohol and centrifuge twice, and dry the obtained precipitate in an oven. The dried material was calcined at 350°C for 3h to obtain a three-dimensional interconnected pore structure visible photocatalyst BiVO 4 .

example 3

[0028] 3.1534g bismuth chloride (BiCl 3 ) dissolved in 200ml ethylene glycol (EG) to form a Bi ion concentration of 0.5mol L -1 After the solution, according to Bi:V=1:2, add 3.6782g sodium vanadate (Na 3 VO 4 ), ultrasonically oscillate for 20 min, and stir well to dissolve it. After the solution was clear and transparent, it was transferred to a constant temperature water bath and kept at 80°C for 4 days to obtain a flocculent precipitate. Remove the EG supernatant, add distilled water to wash, and centrifuge. After repeating this five times, wash with alcohol and centrifuge twice, and dry the obtained precipitate in an oven. The dried material was calcined at 500 °C for 1.5 h to obtain a three-dimensional interconnected pore structure visible photocatalyst BiVO 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| mesopore | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com