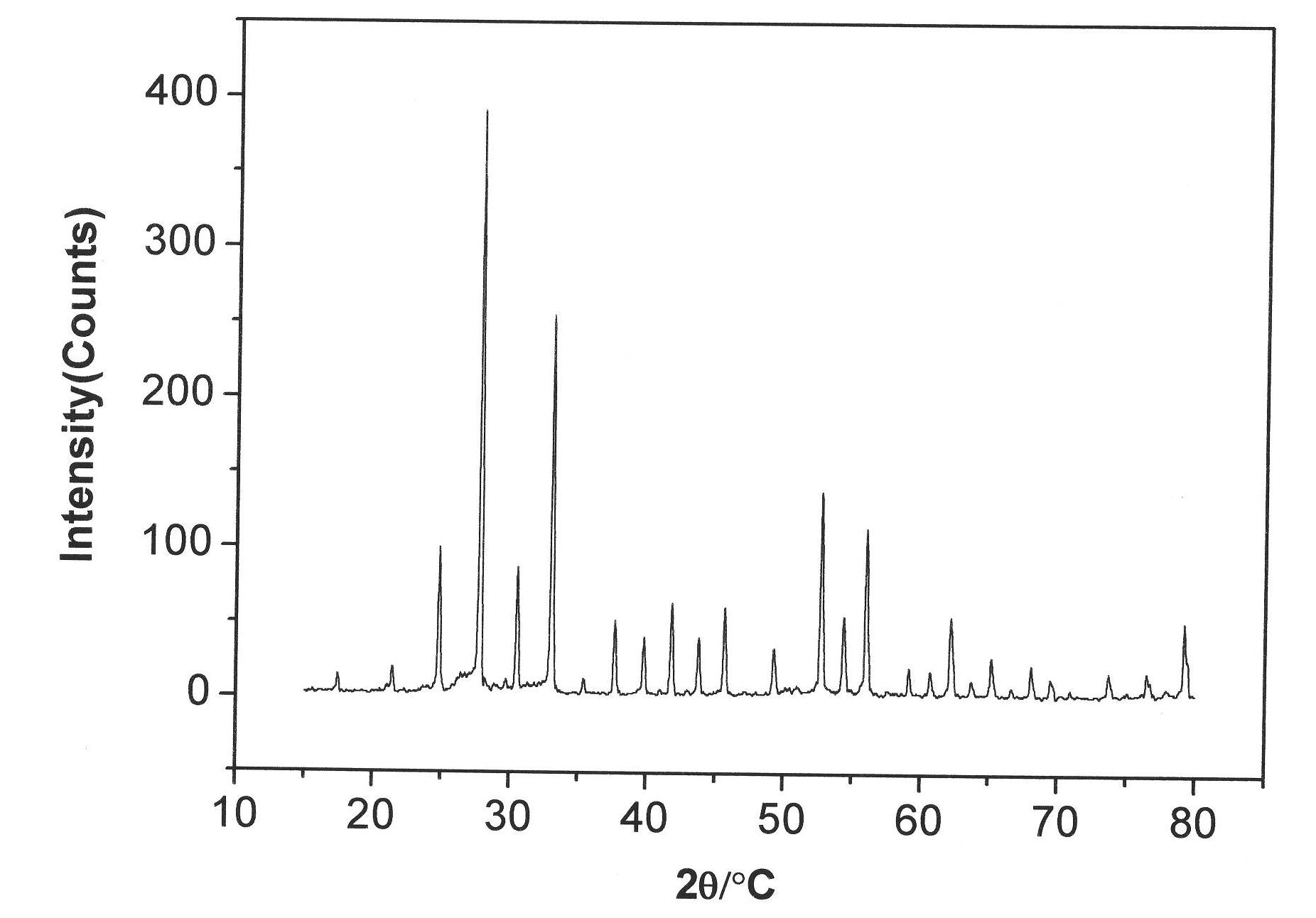

Preparation method of sillenite bismuth silicate microcrystal

A technology of bismuth silicate and microcrystals, applied in chemical instruments and methods, bismuth compounds, inorganic chemistry, etc., can solve the problems of unreported research and achieve the effect of simple preparation process, abundant sources, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

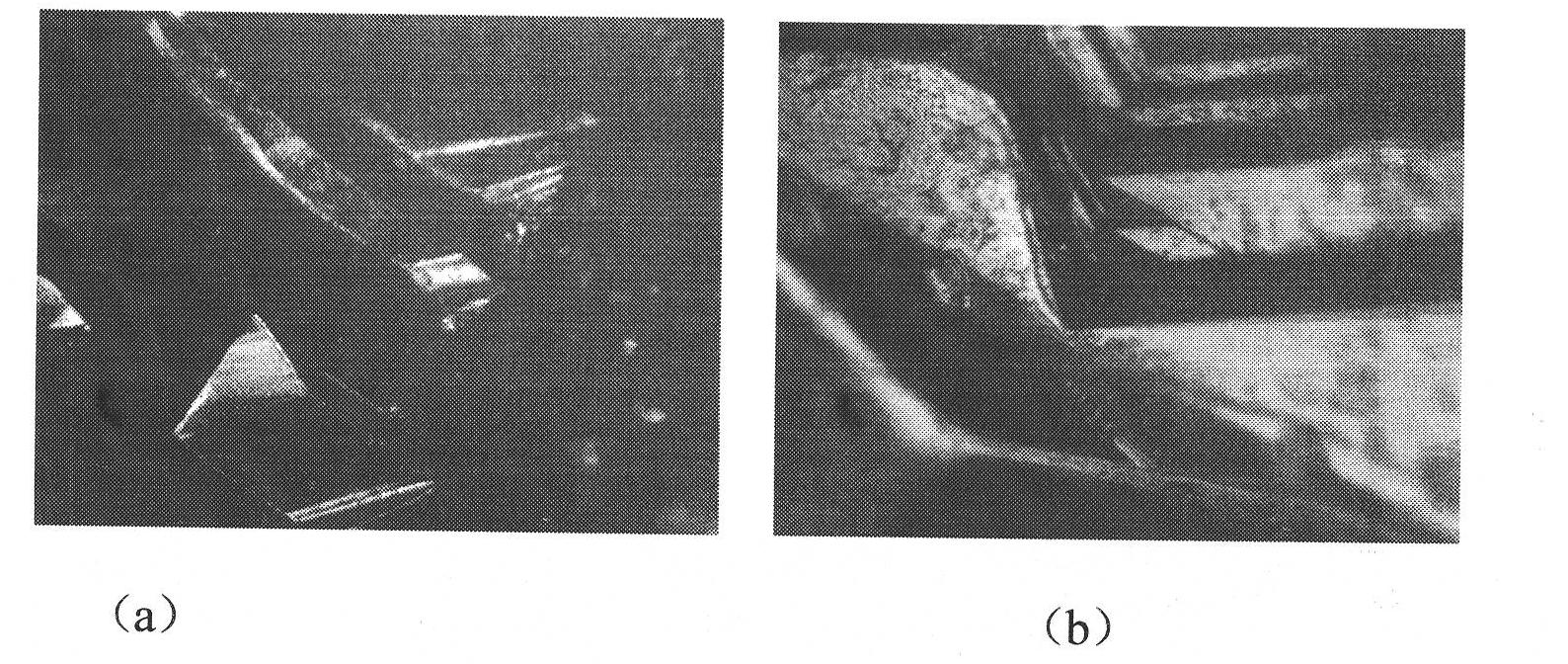

Embodiment 1

[0021] Embodiment 1, 1) at first, bismuth trioxide and quartz sand are pressed Bi 2 o 3 : SiO 2 The mol ratio of =6: 1 is put into the agate emulsion ball milling jar to obtain the mixture, then in the agate emulsion ball milling jar, add the ethanol ball milling of 40% of the mixture quality after 1 hour and the slurry obtained is incubated at 150° C. for 2 Obtain batch material in hours, said quartz sand is through the quartz sand after pickling, and particle size is 300 meshes, and bismuth trioxide adopts particle size to be the analytically pure bismuth trioxide of 200 meshes;

[0022] 2) Then, add 30% of the weight ratio of the batching material into the high-purity alumina crucible with a cover in the muffle furnace in advance, the first feeding temperature is 900 ° C, and add the remaining batching material after 10 minutes of heat preservation, so as to 20°C / min to raise the temperature to 1050°C, cover the crucible and keep it warm for 1 hour, during the heat preser...

Embodiment 2

[0025] Embodiment 2, 1) at first, bismuth trioxide and quartz sand are pressed Bi 2 o 3 : SiO 2 The mol ratio of =6: 1 is put into the agate emulsion ball milling tank to obtain the mixture, then in the agate emulsion ball milling jar, add the ethanol ball milling of 40% of the mixture quality after 3 hours to obtain the slurry at 150 ℃ for 2 hours Obtain batch material in hours, said quartz sand is through the quartz sand after pickling, and particle size is 300 meshes, and bismuth trioxide adopts particle size to be the analytically pure bismuth trioxide of 200 meshes;

[0026] 2) Then, add 30% of the weight ratio of the batch material into the high-purity alumina crucible with a cover in the muffle furnace in advance, the first feeding temperature is 950 ° C, and add the remaining batch material after 15 minutes of heat preservation, so as to Heat up to 1050°C at 24°C / min, cover the crucible and keep it warm for 2 hours, and stir the molten glass liquid or batch for 1min ...

Embodiment 3

[0029] Embodiment 3, 1) at first, bismuth trioxide and quartz sand are pressed Bi 2 o 3 : SiO 2 The mol ratio of =6: 1 is put into the agate emulsion ball milling tank to obtain the mixture, then in the agate emulsion ball milling jar, add the ethanol ball milling of 40% of the mixture quality after 5 hours to obtain the slurry at 150 ℃ for 2 hours Obtain batch material in hours, said quartz sand is through the quartz sand after pickling, and particle size is 300 meshes, and bismuth trioxide adopts particle size to be the analytically pure bismuth trioxide of 200 meshes;

[0030] 2) Then, add 30% of the weight ratio of the batch into the high-purity alumina crucible with a cover in the muffle furnace in advance. 30°C / min to raise the temperature to 1050°C, cover the crucible and keep it warm for 5 hours, during the keep warm process, stir the molten glass liquid or batch material for 1min every 1 hour;

[0031]3) After the heat preservation is over, remove the crucible cove...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com