Drying method of grape seed proanthocyanidin extract

A technology of proanthocyanidin and drying method, applied in the direction of organic chemistry, etc., can solve the problems of high energy consumption and production cost, large investment in freeze-drying equipment, affecting product quality and yield, etc., so as to maintain physical and chemical properties and production capacity Large, low moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

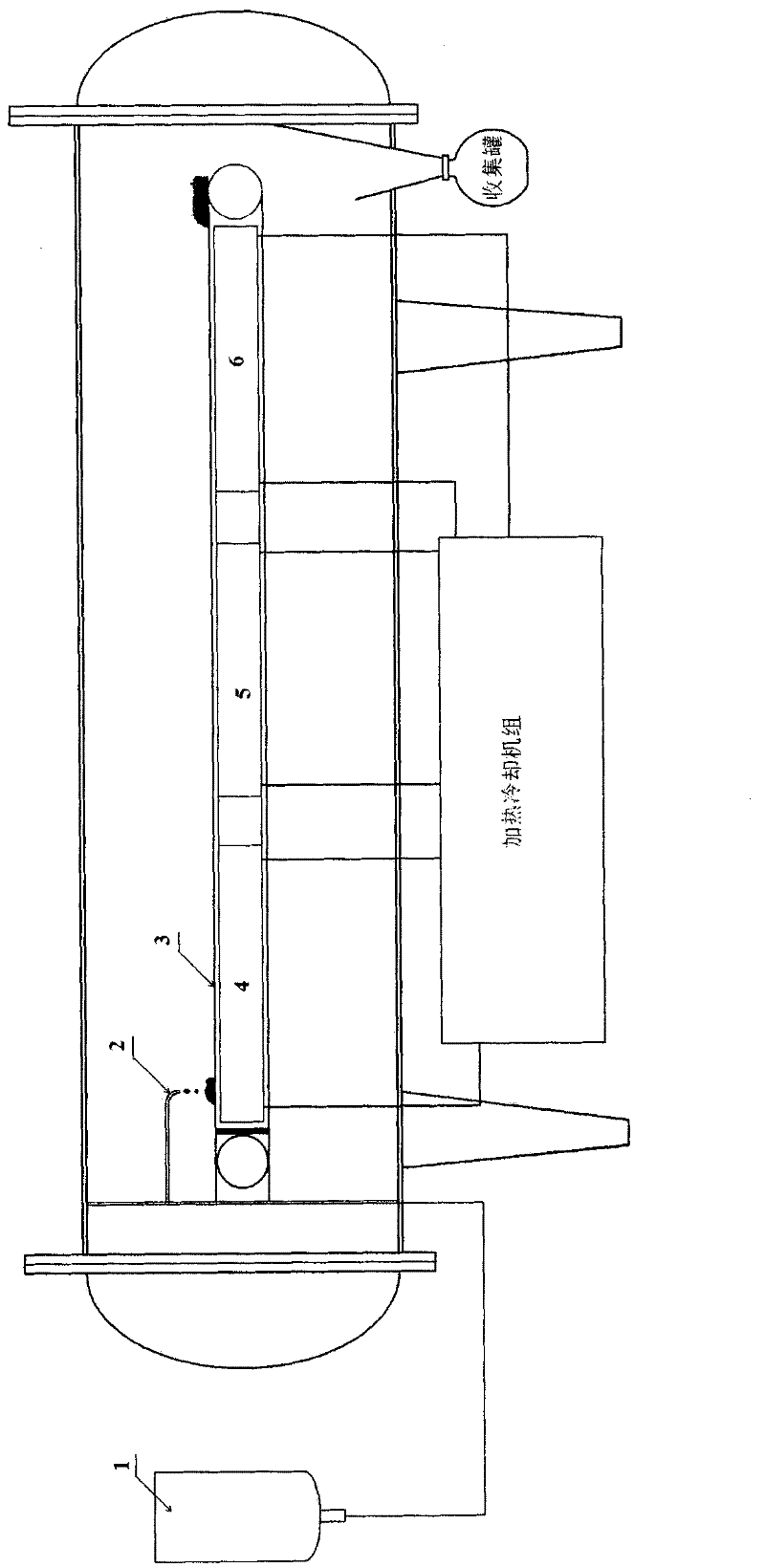

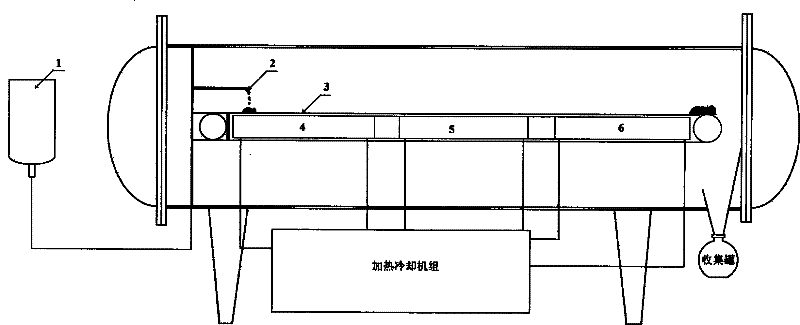

[0016] see figure 1 , the density is 1145kg / m 3 The proanthocyanidin extract is preheated to 30°C in the vacuum belt dryer feed tank 1, and is evenly coated on the conveyor belt 3 by the swing of the distributor 2 at a feed rate of 1.4kg / h under vacuum conditions. On the top, the conveyor belt runs at a speed of 2.4m / h, and the proanthocyanidin extract passes through the first heating section 4 with a temperature of 80°C and the second heating section 5 with a temperature of 80°C along with the conveyor belt, and finally passes through a temperature of 25~ The cooling section 6 at 35°C forms a continuous, porous and loose dry extract. When the dry extract reaches the end of the equipment, the scraper set at the end scrapes it off the conveyor belt and falls into the shredder. , the crushed dry extract enters the product collection tank. Measured by the first method of moisture determination in the appendix of "Chinese Pharmacopoeia", the moisture content of the dry extract i...

Embodiment 2

[0018] see figure 1 , with the extractant in Example 1 at a feed rate of 2.1kg / h, on the basis that the rest of the conditions are the same, adjust the temperature of the first heating section 4 to be 90°C, and the temperature of the second heating section 5 to be 90°C, The temperature of the cooling section 6 is 25-35°C. The moisture content of the dry extract is 1.06%, and the drying speed is 1.23kg / h.

Embodiment 3

[0020] see figure 1 , with the extractant in Example 1 at a feed rate of 2.8kg / h, on the basis that the rest of the conditions are the same, adjust the temperature of the first heating section 4 to be 100°C, and the temperature of the second heating section 5 to be 100°C, The temperature of the cooling section 6 is 25-35°C. Measured by the first method of water determination in the appendix of "Chinese Pharmacopoeia", the moisture content of the dry extract is 0.23%, and the drying speed is 1.65kg / h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com