Foam cement composite bamboo

A foamed cement and bamboo technology, applied in joists, girders, trusses and other directions, can solve problems such as inconvenient fixed connection, and achieve the effects of improving physical properties and application breadth, low cost, and increasing compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

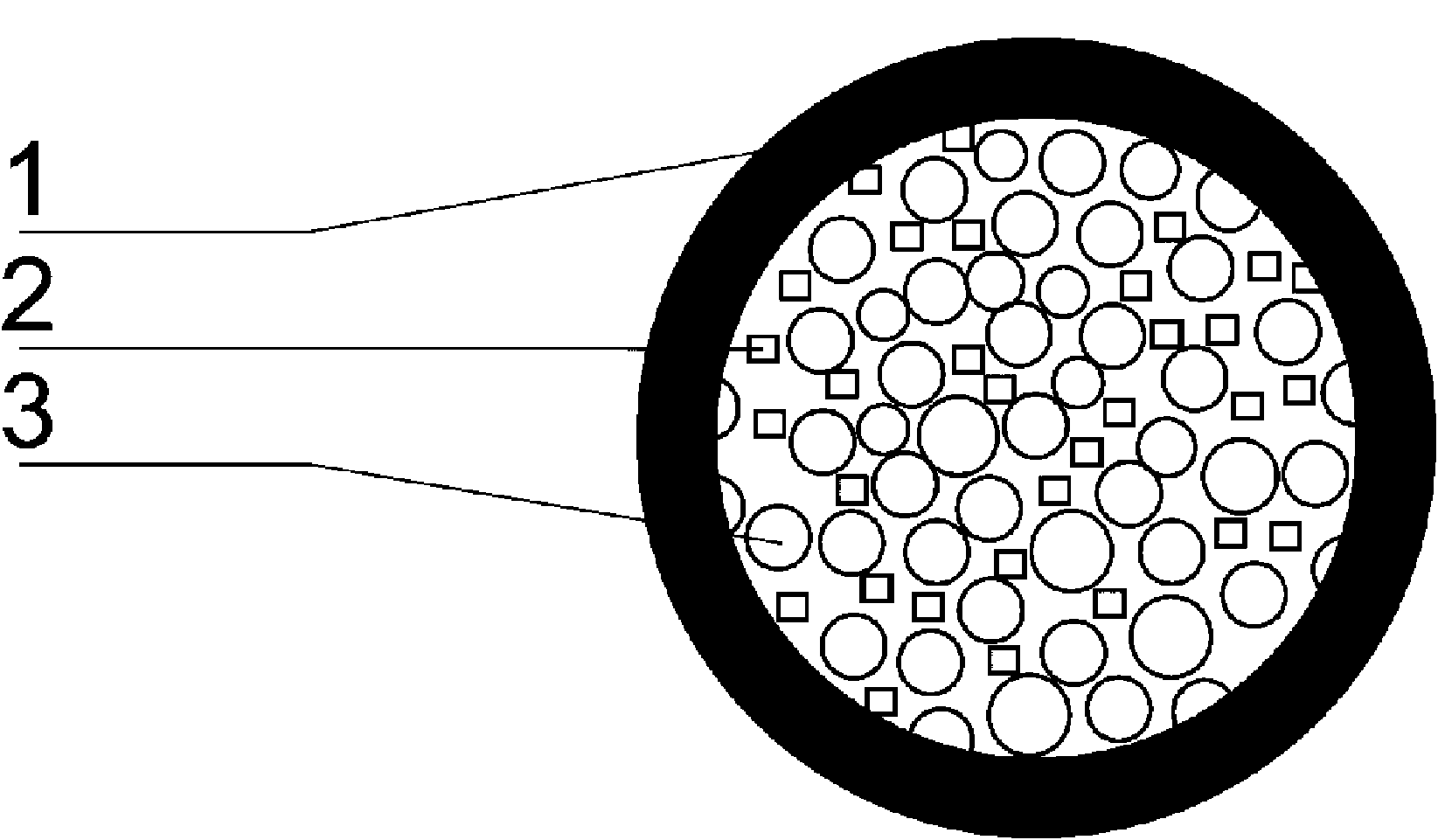

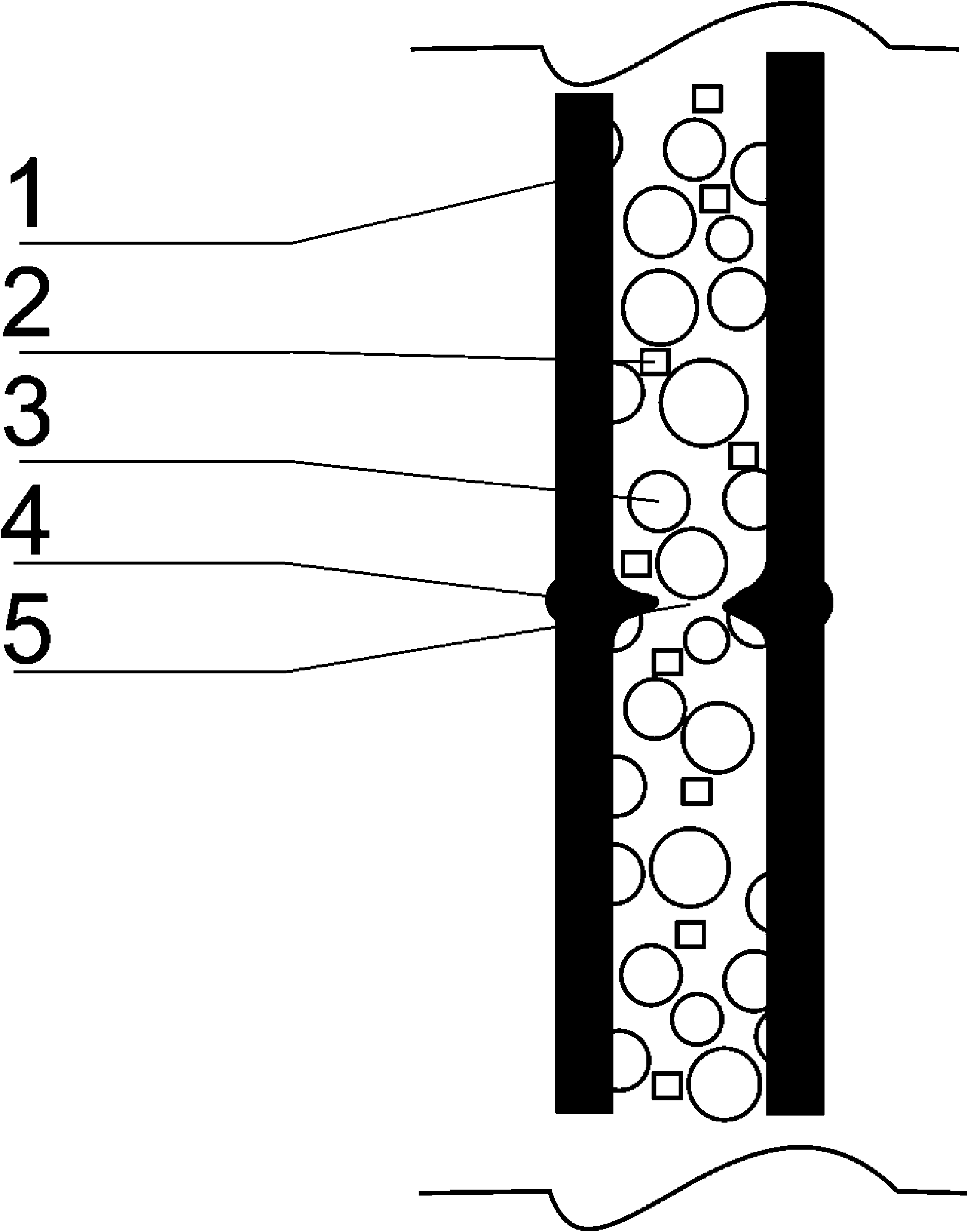

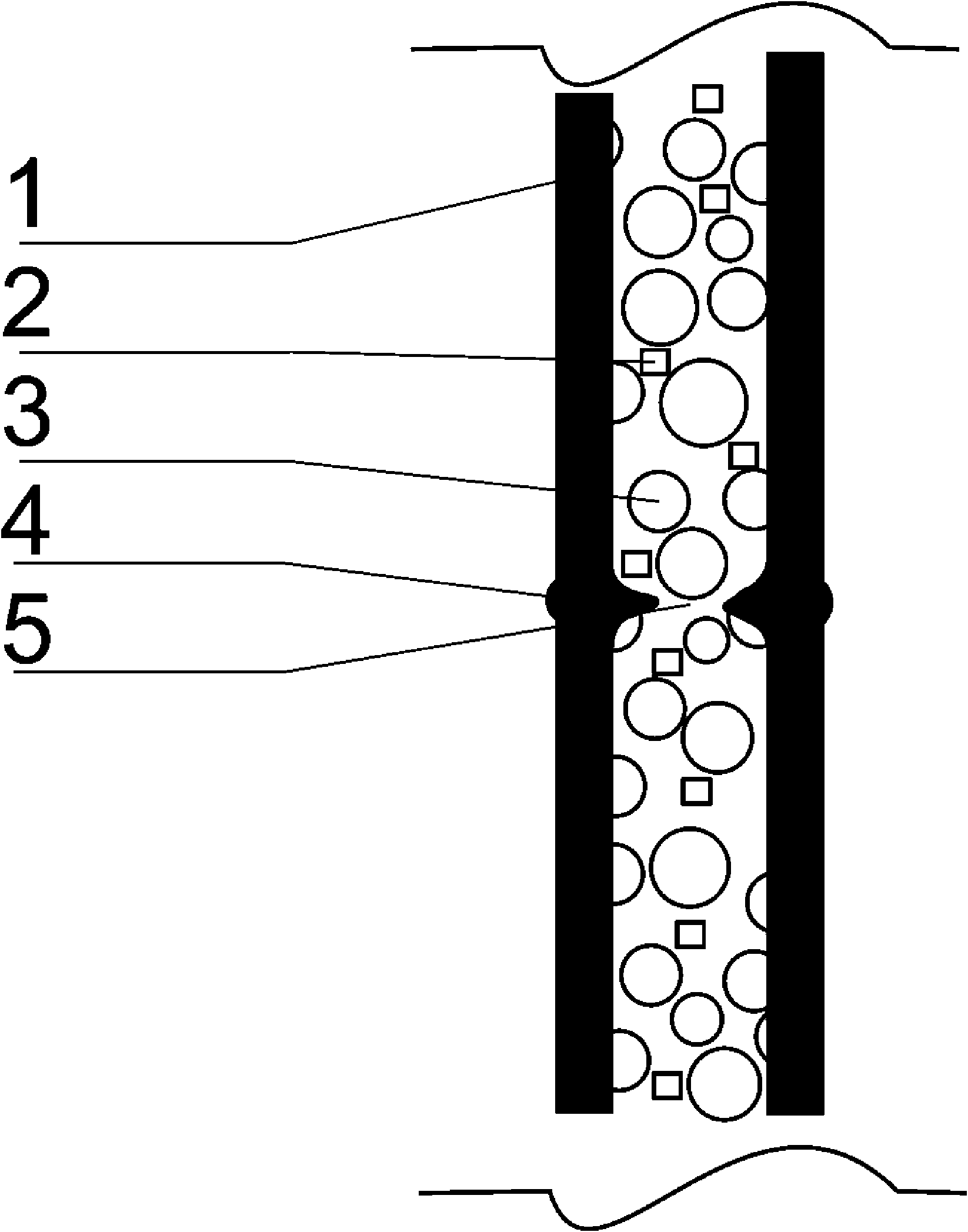

[0050] as the picture shows:

[0051] A foamed cement composite bamboo material is characterized in that a bamboo diaphragm opening 5 penetrating through the diaphragm of the raw bamboo bamboo 4 is arranged inside the raw bamboo 1, and the foamed cement 3 is poured into the cavity inside the raw bamboo 1 according to the known foamed cement production process Foaming in the closed inner cavity of raw bamboo 1 can also be mixed with reinforced fiber reinforcement filler 2, so as to closely contact and occlude the composite connection with the remaining diaphragm between the inner cavity of raw bamboo 1 and bamboo joint 4, the above-mentioned reinforced fiber reinforcement filler 2 refers to plant fiber, glass fiber, metal fiber, polymer fiber or a mixture of the above fibers. According to the use of bamboo, the physical properties of bamboo can be changed by adding different proportions of reinforcing fiber filler 2 and controlling the density of foamed cement. .

[0052] In a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com