Method for preparing composite thin plate based on glass carbon and carbon nanotube

A carbon nanotube and composite sheet technology, which is applied in the fields of nanostructure manufacturing, nanotechnology, nanotechnology, etc., and can solve the problems of fragile glassy carbon and other problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

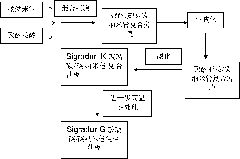

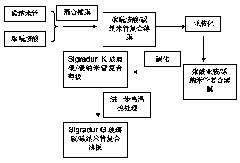

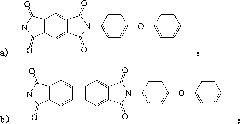

[0024] Such as figure 1 Shown, the N, N-dimethyl of the polyamic acid (PMDA / ODA system) that the percentage by weight is 0.5% multi-walled carbon nanotube (outer diameter 30nm, internal diameter 20nm, length micron level) in 10% solid content After ultrasonic dispersion in acetamide solution, apply a film on the substrate, control the thickness to 300 microns, heat at 60°C for 1 hour, heat at 90°C for 1 hour, heat at 120°C for 1 hour, and heat at 150°C for 1 hour. After removing the polar solvent, In a vacuum oven, heat at 180°C for 1 hour, 200°C for 1 hour, 250°C for 1 hour, and 300°C for 1 hour to complete the imidization, thereby forming a polyimide precursor film with a thickness of about 30 microns. The obtained composite film has a tensile strength of 220 MPa.

Embodiment 2

[0026] The procedure is the same as in Example 1, the weight percentage of multi-walled carbon nanotubes is changed to 50%, and the solid content of polyamic acid is reduced to 5%. The composite film obtained at this time had a tensile strength of 200 MPa.

Embodiment 3

[0028] The steps are as in Example 1, changing the polyamic acid of the PMDA / ODA system into the polyamic acid of the s-BPDA / ODA system. The composite film obtained at this time had a tensile strength of 232 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com