Nickel-system polybutadiene rubber composite anti-aging agent with anti-yellowing efficiency

A polybutadiene rubber and anti-aging agent technology, which is applied in the field of composite anti-aging agents, can solve the problems of unsatisfactory performance, easy oxidation and discoloration, and poor anti-aging performance, so as to improve anti-aging efficiency, Good anti-aging performance, not easy to migrate and spread

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

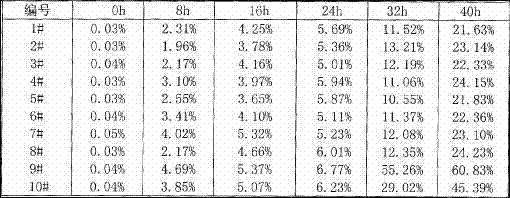

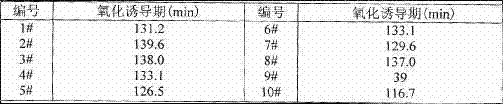

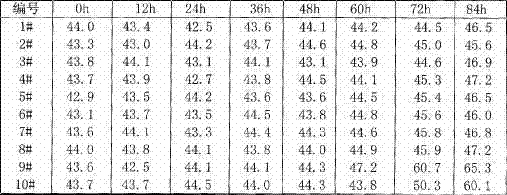

[0067] Weigh 2000 grams of raw material BR, 0.80 grams of 1# composite antioxidant powder of the present invention, fully stir and mix evenly. After coagulation and drying, a gel sample of an effective BR anti-aging composition was obtained, that is, the 1# sample.

Embodiment 2

[0069] Weigh 2000 grams of raw material BR, 0.90 grams of 2# composite antioxidant powder of the present invention, fully stir and mix evenly. After coagulation and drying, a gel sample of an effective BR anti-aging composition was obtained, that is, the 2# sample.

Embodiment 3

[0071] Weigh 2000 grams of raw material BR, 0.73 grams of 3# composite antioxidant powder of the present invention, fully stir and mix evenly. After agglomeration and drying, a gel sample of an effective BR anti-aging composition was obtained, i.e. 3# sample.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxidation induction time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com