Microwave ECR plasma-aid magnetron sputtering deposition device

A plasma and magnetron sputtering technology, applied in thin film technology and application fields, can solve the problems of low sputtering deposition rate, low auxiliary bombardment effect, poor film quality, etc., and achieve the effect of reducing the cost of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

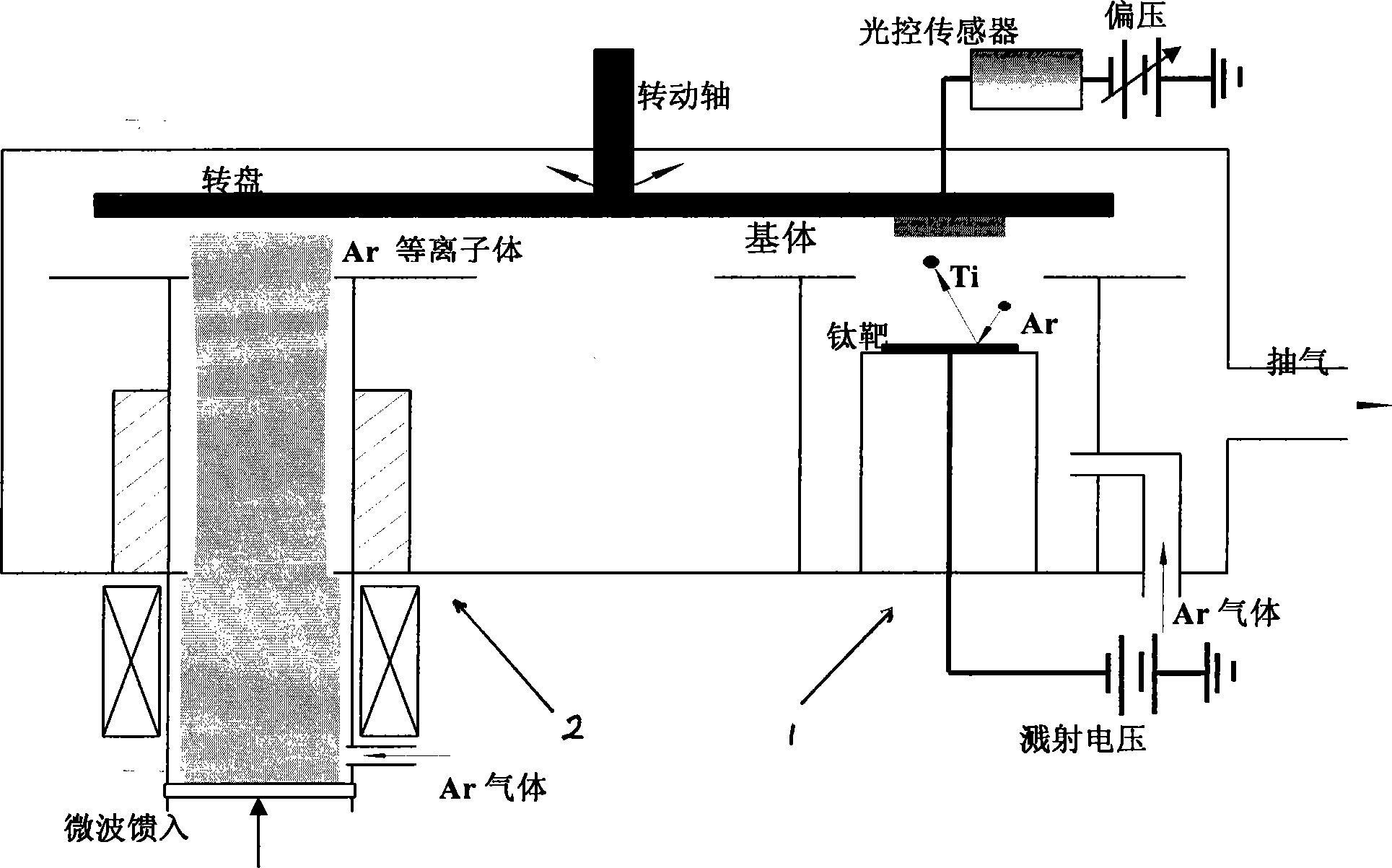

[0037] The device of the present invention comprises a magnetron sputtering area 1 and an ECR plasma bombardment area 2 .

[0038] The sputtering area and the plasma bombardment area are located at the two ends of the vacuum chamber at an angle of 90 degrees. In the device, the substrate initially stays on the sputtering area. The distance between the ECR plasma discharge chamber and the substrate is 300mm. The 2.4GHz microwave enters the discharge chamber after coupling the rectangular waveguide and the microwave window of the discharge chamber. When the magnetic field strength of the discharge chamber makes the cyclotron frequency of the electrons in the magnetic field equal to the microwave frequency, the microwave and the cyclotron produce resonance energy exchange. High-density and highly ionized plasma can be produced. In order to avoid the mutual interference of the discharge gas in the sputtering area and the ECR plasma source area, the present invention welds an annu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com