Process for treating tail gas containing insoluble solvent

A water-insoluble, tail gas technology, applied in the direction of steam condensation, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of unsatisfactory washing effect, large system resistance, adverse effects, etc., to achieve small footprint, overcome resistance, Easy to install effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

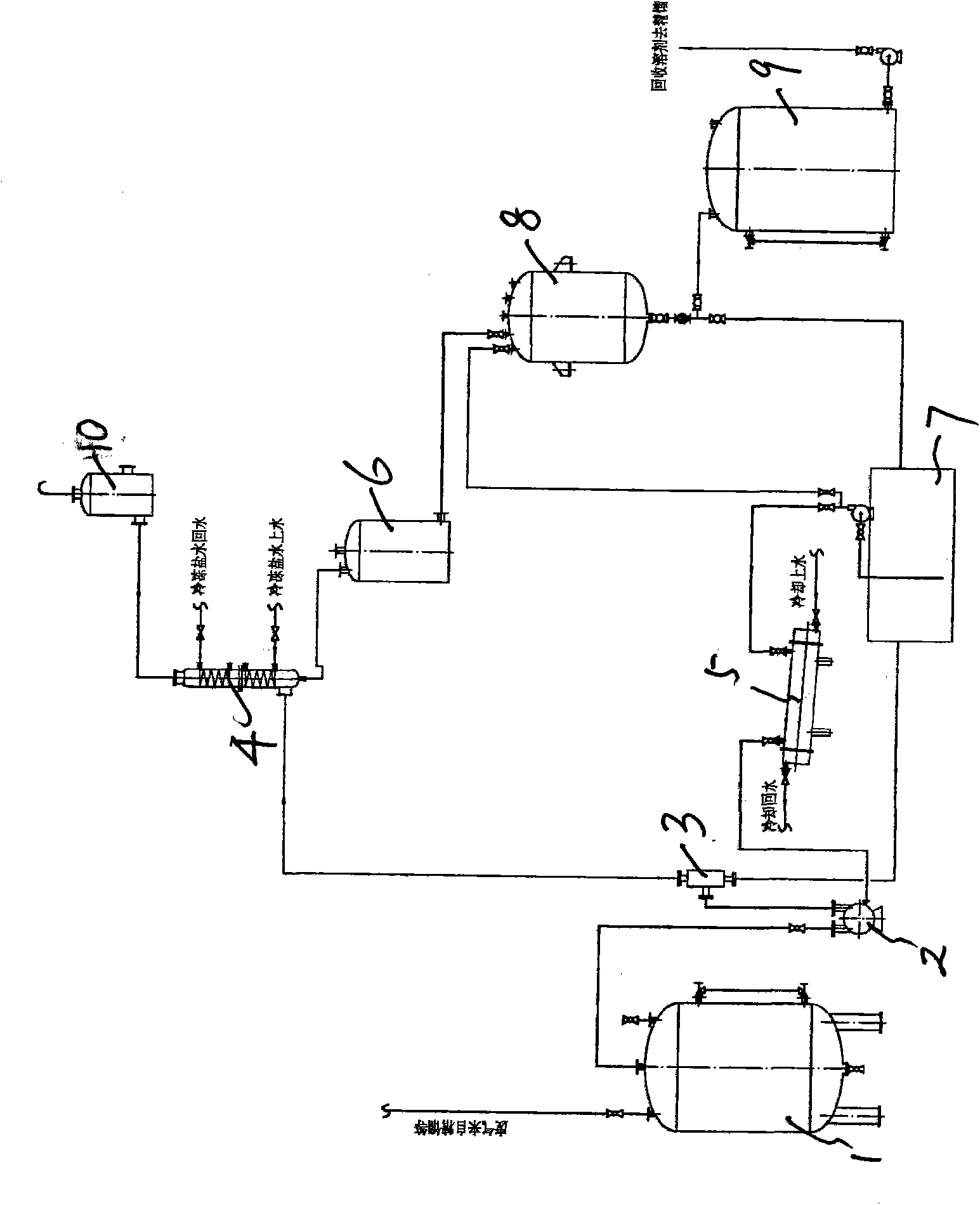

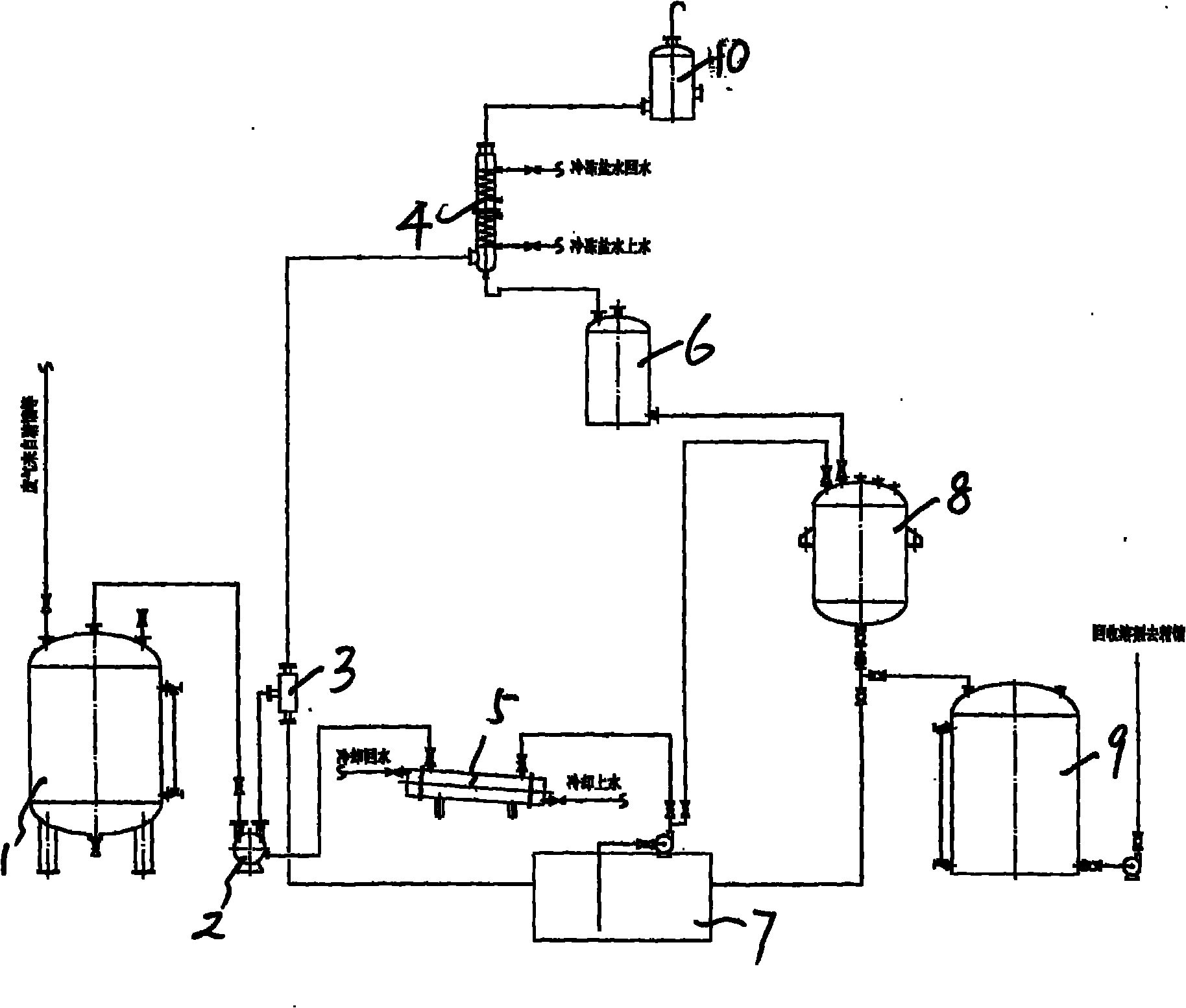

[0019] A process for treating tail gas containing insoluble solvents. The tail gas containing water-insoluble organic solvents enters the water ring vacuum pump 2 through the tail gas buffer tank 1, and the tail gas entering the water ring vacuum pump is fully mixed with the working fluid of the water ring vacuum pump. The water and gas mixture passes through the water ring vacuum pump. The gas and liquid separation device 3 at the outlet of the ring vacuum pump is used for separation, the liquid is returned to the system for recycling, and the gas is further recovered through the glass condenser 4 installed at the tail, and the organic solvent that may escape is further recovered, and then filtered and adsorbed by the activated carbon filter 10 and then emptied The circulating fluid of the water ring vacuum pump is cooled and lowered in temperature by the cooler 5; the liquid in the recycling liquid tank 6 of the glass condenser and the circulating water pool 7 of the circulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com