Method for preparing carborundum-coke ytterbium silicate composite coating on surface of carbon/carbon composite material

A carbon composite material and composite coating technology, which is applied in the field of preparing SiC-Yb2Si2O7 composite coating on the surface of carbon/carbon composite material, can solve the problems of poor bonding force, unevenness, low density, etc. The effect of uniform coating and high bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

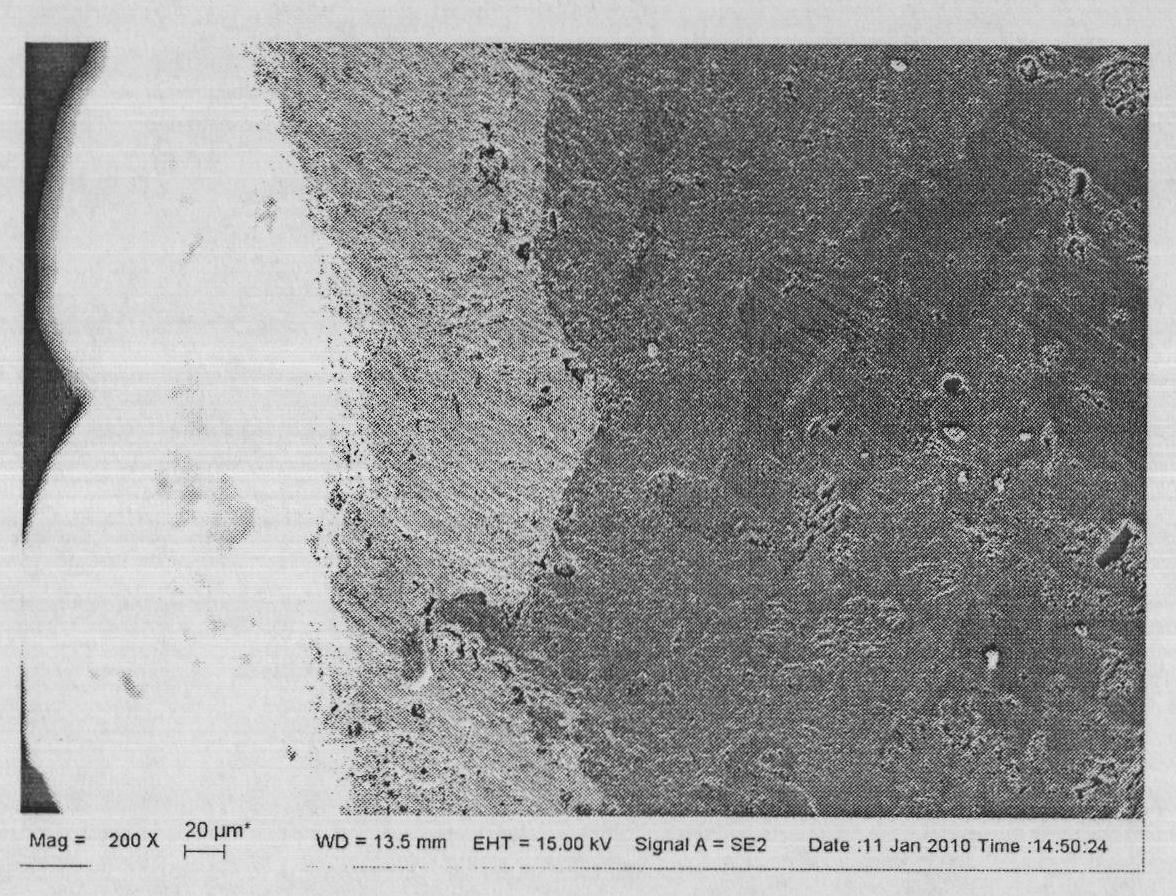

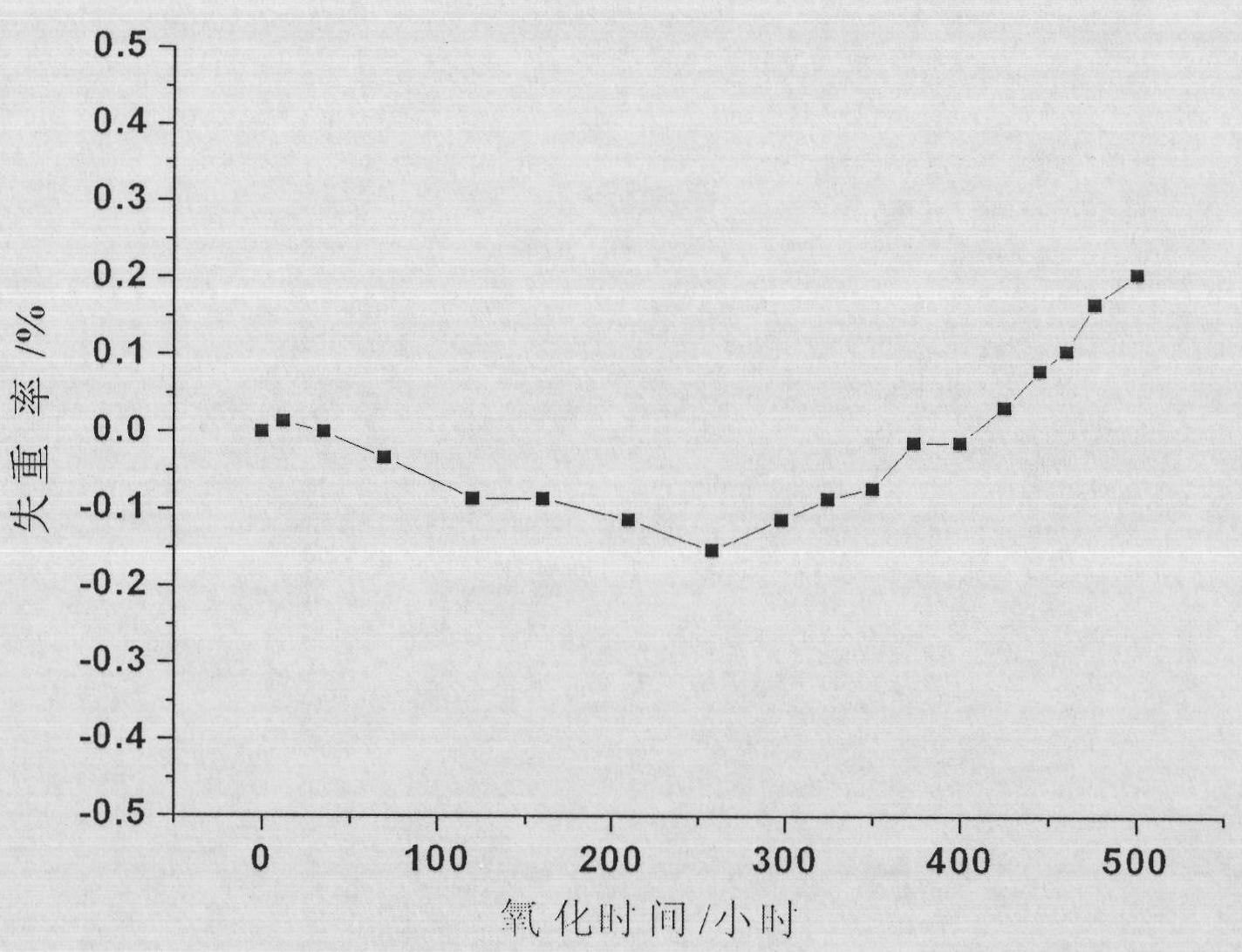

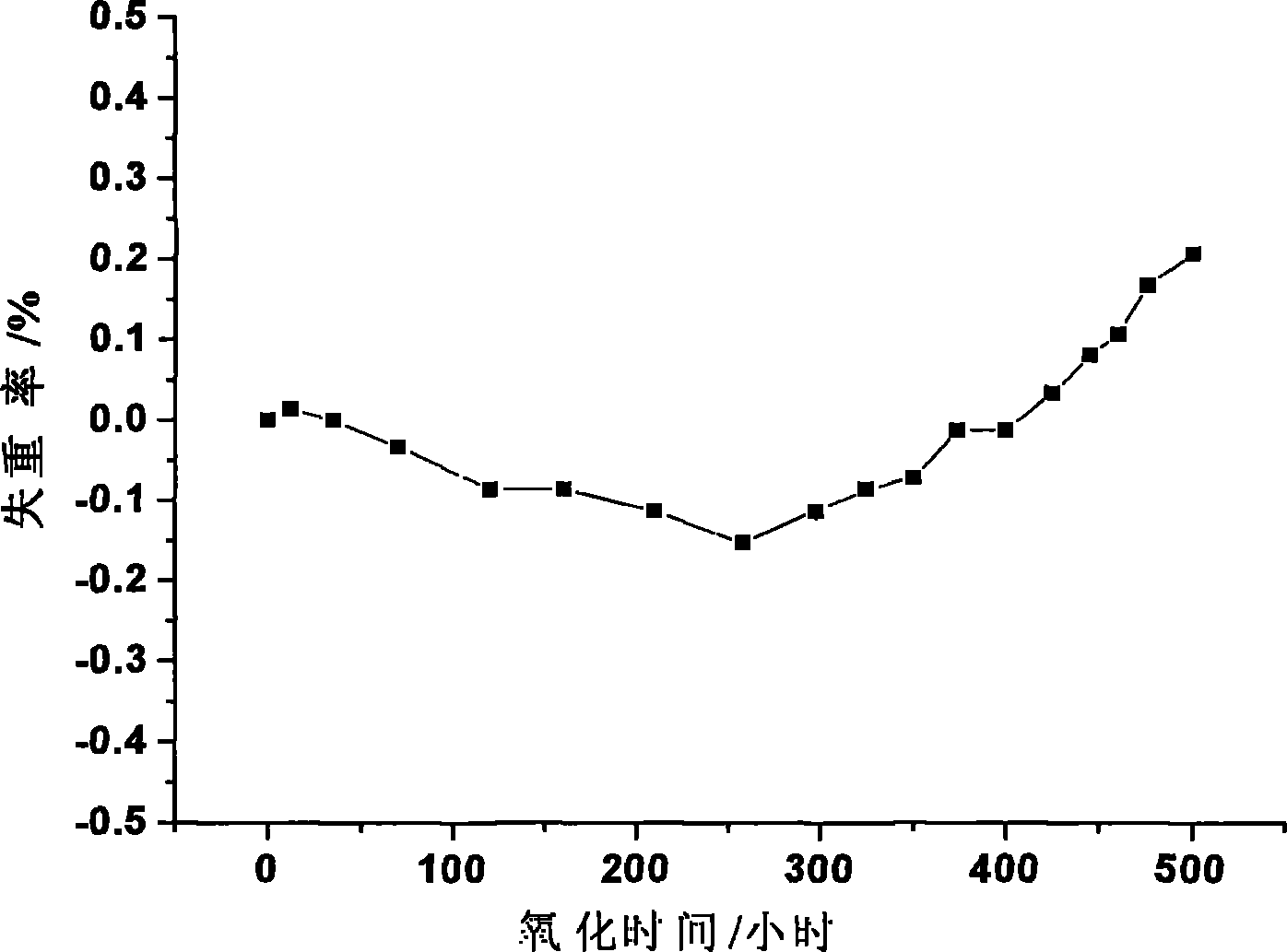

Image

Examples

Embodiment 1

[0014] Step 1: Polish the carbon / carbon composite material, ultrasonically clean it in absolute ethanol for 20 minutes, and dry it at 110°C;

[0015] Step 2: Weigh 65g Si powder, 25g C powder, 10g Al respectively 2 o 3 powder, placed in a ball mill jar, mixed and ball milled for 1 hour to make embedding powder; take half of the embedding powder and put it into a graphite crucible, put it into the carbon / carbon composite material treated in step 1, and then put Cover with the other half of the embedding powder, and add a graphite crucible cover; put the graphite crucible into a vertical vacuum furnace, and after vacuuming, raise the furnace temperature to 1900°C at a heating rate of 5°C / min, keep it warm for 3 hours, and turn off the power Natural cooling, the whole process is protected by argon gas, the flow rate of argon gas is 2L / min, and the carbon / carbon composite material with SiC inner coating is obtained;

[0016] Step 3: Put Yb 2 o 3 Powder and SiO 2 Powder press ...

Embodiment 2

[0020] Step 1: Polish the carbon / carbon composite material, ultrasonically clean it in absolute ethanol for 30 minutes, and then dry it at 120°C;

[0021] Step 2: Weigh 85g Si powder, 10g C powder, 5g Al respectively 2 o 3 powder, placed in a ball mill jar, mixed and ball milled for 2 hours to make embedding powder; take half of the embedding powder and put it into a graphite crucible, put it into the carbon / carbon composite material treated in step 1, and put Cover with the other half of the embedding powder, add a graphite crucible cover; put the graphite crucible into a vertical vacuum furnace, and after vacuuming, raise the furnace temperature to 2300°C at a heating rate of 7.5°C / min, keep it warm for 1h, and turn off the power Natural cooling, the whole process is protected by argon gas, the flow rate of argon gas is 1L / min, and the carbon / carbon composite material with SiC inner coating is obtained;

[0022] Step 3: Put Yb 2 o 3 Powder and SiO 2 Powder press Yb 2 o...

Embodiment 3

[0026] Step 1: Polish the carbon / carbon composite material, ultrasonically clean it in absolute ethanol for 40 minutes, and then dry it at 130°C;

[0027] Step 2: Weigh 75g Si powder, 15g C powder, 10g Al respectively 2 o 3 powder, placed in a ball mill jar, mixed and ball milled for 3 hours to make embedding powder; take half of the embedding powder and put it into a graphite crucible, put it into the carbon / carbon composite material treated in step 1, and then put Cover with the other half of the embedding powder, add a graphite crucible cover; put the graphite crucible into a vertical vacuum furnace, and after vacuuming, raise the furnace temperature to 2100°C at a heating rate of 10°C / min, keep it warm for 2 hours, and turn off the power Natural cooling, the whole process is protected by argon gas, the flow rate of argon gas is 3L / min, and the carbon / carbon composite material with SiC inner coating is obtained;

[0028] Step 3: Put Yb 2 o 3 Powder and SiO 2 Powder pre...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap