Doping method of scheelite luminescent material

A luminescent material, scheelite technology, applied in the field of rare earth doping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1. Treatment time on CaWO 4 Polycrystalline film doped with Tb 3+ Effect of Concentration

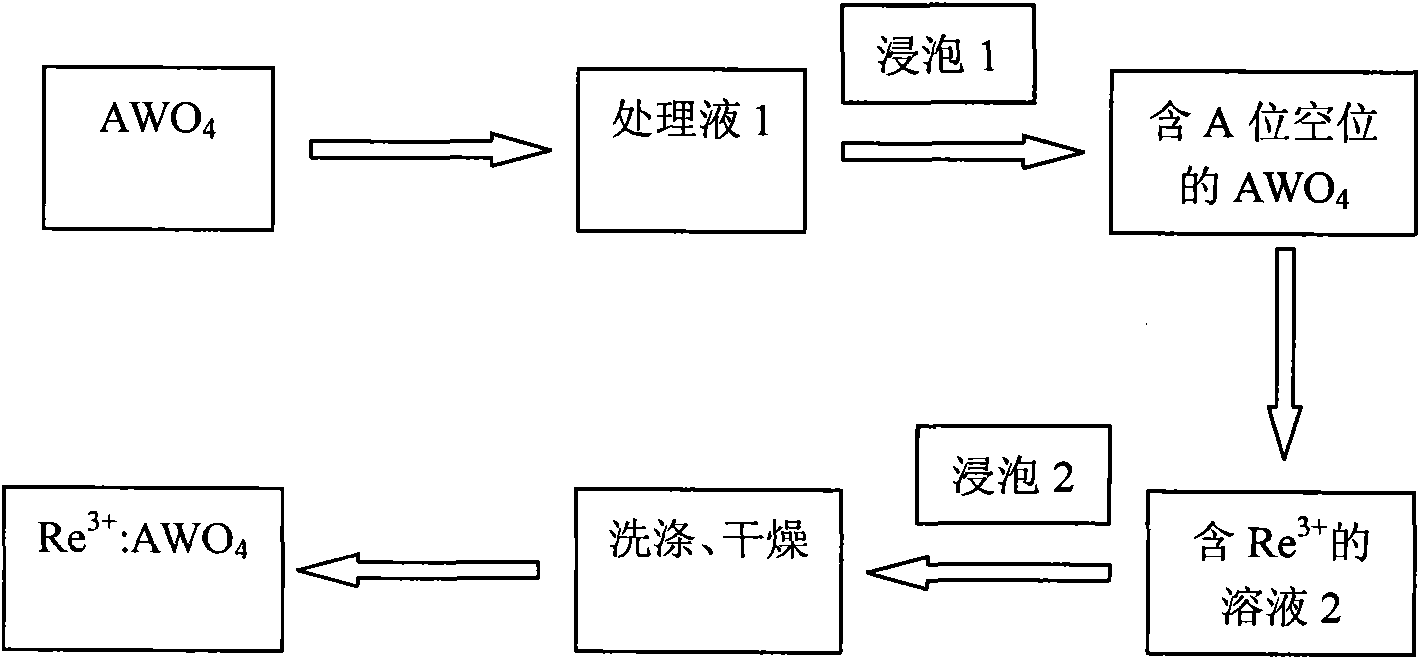

[0022] figure 1 The two-step processing shown (creation of A-site vacancies and rare-earth ion filling processing) can often be combined into one in actual operation. Treatment time and Tb in film 3+ There is the following relationship between the contents (as shown in Table 1). It can be seen from Table 1 that the doping concentration can also be effectively controlled by controlling the time of doping treatment.

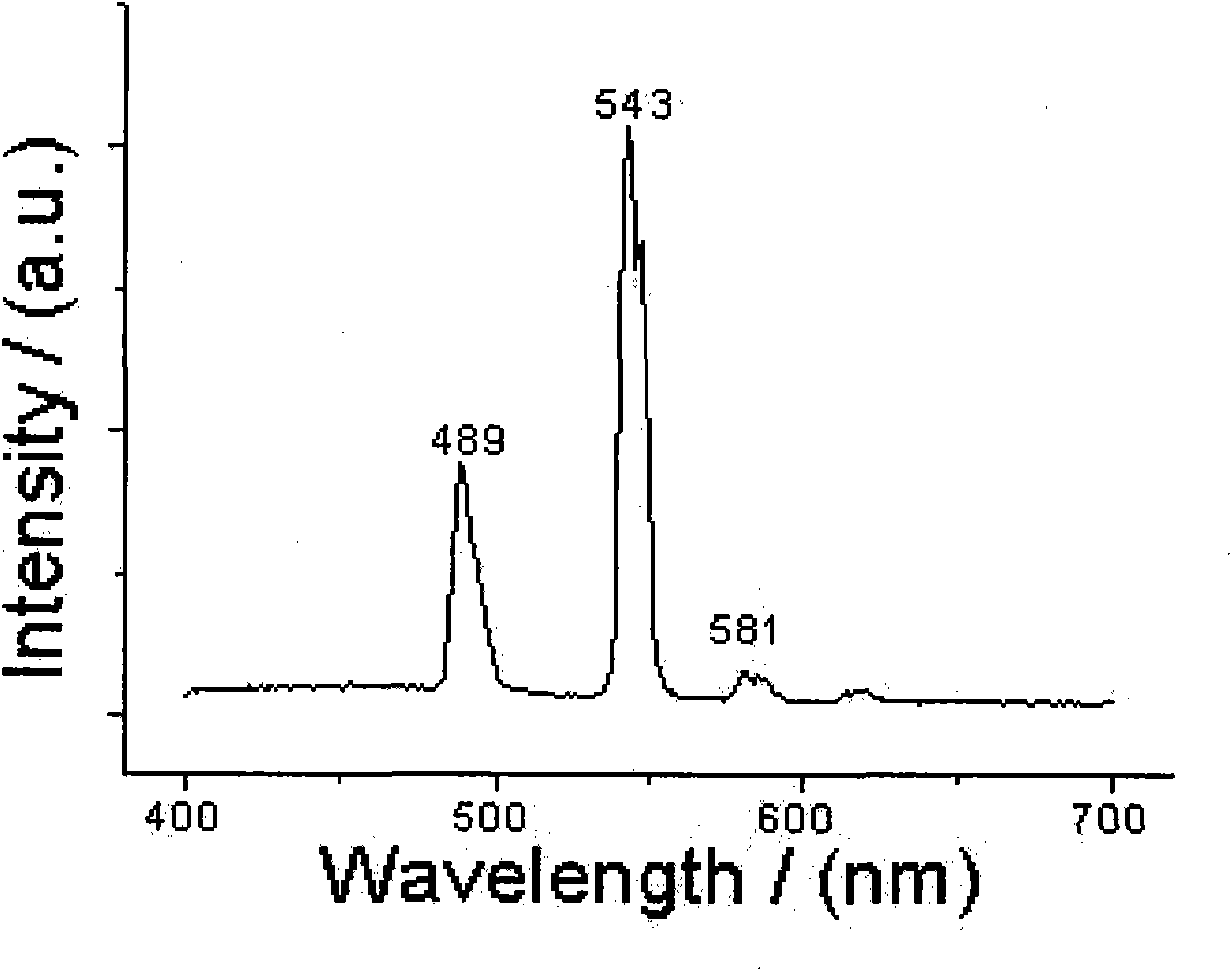

[0023] figure 2 CaWO 4 Polycrystalline film doped with Tb 3+ Photoluminescence spectra after 8 min of treatment. Under the excitation of 237nm light, CaWO 4 The broadband emission of the substrate near 450nm was suppressed, and a stronger green light was observed, namely Tb 3+ The luminescence of ions, and the half-maximum width of the line spectrum is less than 10nm. This shows that post-processing can achieve CaWO 4 Rare earth doping of polycrys...

Embodiment 2

[0026] Embodiment 2. Effect of Eu, Tb ratio on Eu, Tb content in film in the treatment solution

[0027] Table 2 shows the relationship between the content of Eu and Tb in the film and the ratio of Eu and Tb in the treatment solution. It can be seen from the table that by changing the ratio of Eu and Tb in the treatment solution, the doping concentration of Eu and Tb elements in the film can be controlled.

[0028] Table 2 The relationship between the content of Eu and Tb in the film and the ratio of Eu and Tb in the treatment solution

[0029] Eu / Tb in the treatment solution

Embodiment 3

[0030] Example 3. CaWO synthesized by precipitation method 4 Doped Tb content of powder

[0031] CaWO synthesized by precipitation method 4 Powders can also be doped using the doping methods introduced in this invention. Table 3 gives the Tb 3+ CaWO treated for 250 minutes in a solution with an ion concentration of 0.02 mol / l 4 Powder composition test results. According to the data in the table, it can be inferred that in CaWO 4 A luminescent shell layer with a high concentration of rare earth is formed in the surface layer of the microcrystal, and the shell / core structure of the luminescent shell layer-matrix not only helps to improve the luminescent performance, but also saves the amount of rare earth.

[0032] Table 3Tb 3+ :CaWO 4 Comparison list of powder surface composition and body composition

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com