Regeneration process of high temperature gas desulfurizer

A desulfurizer and gas technology, which is applied in the petroleum industry, combustible gas purification, sulfur preparation/purification, etc., can solve the problems of easy pulverization or sintering of desulfurizers, decreased desulfurization performance of desulfurizers, and low recovery rate of elemental sulfur, etc. Achieve the effect of improving operability, stable regeneration temperature and simplifying process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0034] First, weigh 395 grams of dried steel mill red mud with an iron oxide content of more than 55%, add 75 grams of structural additive brick and tile soil, then add 25 grams of pore-forming agent carboxymethyl cellulose, and finally add additive graphite 5 grams, after grinding and mixing these components, add 1750ml of water and knead, the raw material after kneading is made into strips with an extruder, the diameter of the strips is φ2~3mm, the length of the strips is L3~5mm, after drying at room temperature, Dry in an oven at 120°C for 2 hours, and finally bake in a muffle furnace at 750°C for 5 hours to finally prepare an iron oxide-based high-temperature gas desulfurizer sample; the prepared iron oxide-based high-temperature gas desulfurizer sample is desulfurized and desulfurized. The conditions are that the inner diameter of the reactor is 20mm, the particle size of the desulfurizer is φ2mm, the length of the desulfurizer is L3mm, the filling volume is 10ml, the reac...

Embodiment approach 2

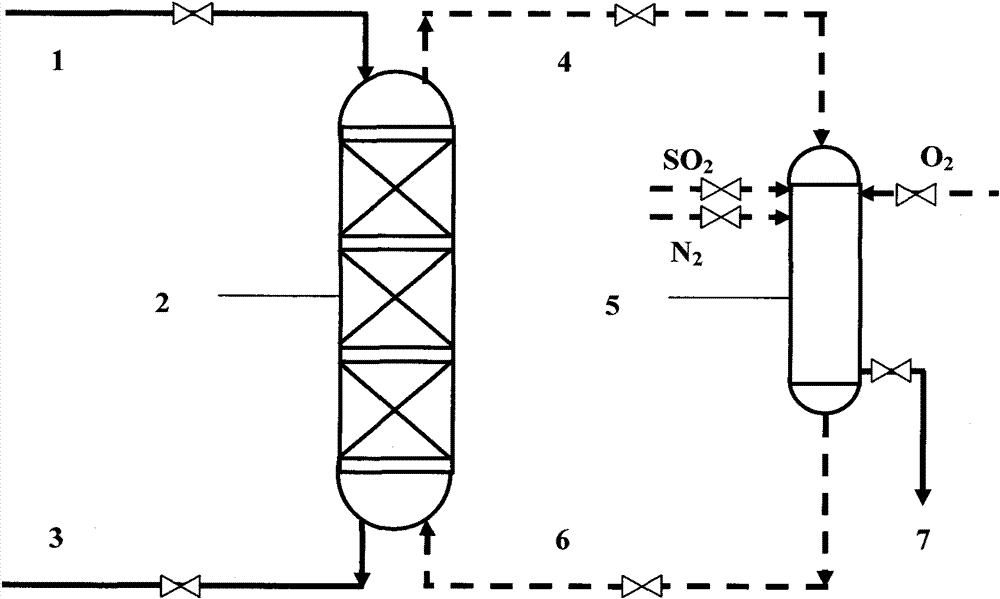

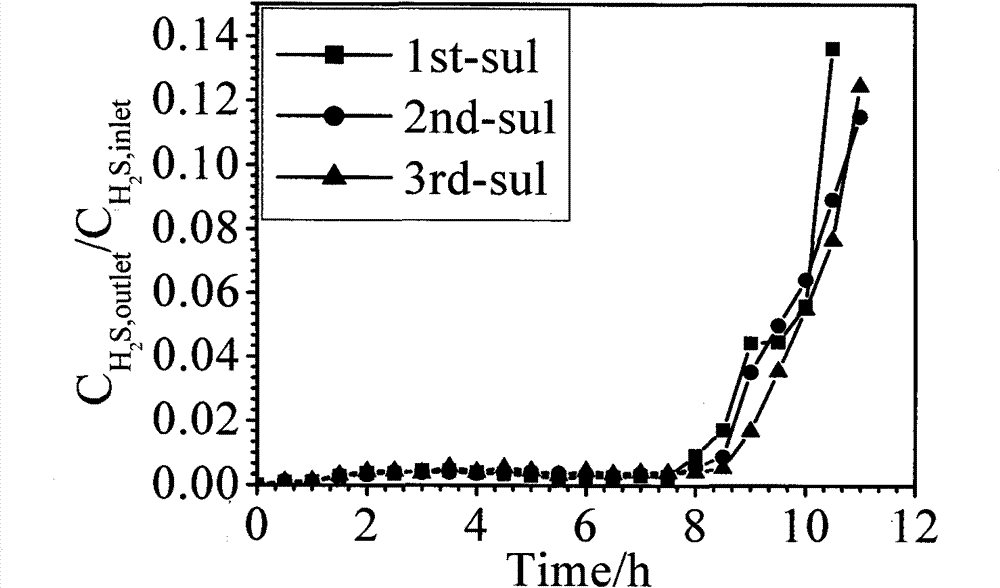

[0036] The desulfurized iron oxide high-temperature gas desulfurizer sample obtained from Embodiment 1 is directly regenerated in the desulfurization reactor, at a space velocity of 3000h -1 , atmospheric pressure, 20vol.%O prepared by a single gas mixture 2 / SO 2 and 80vol.%N 2 The composition of the regeneration gas enters from the bottom of the reactor, where O 2 / SO 2 The volume ratio is 1:100, and the sulfur dioxide concentration at the inlet and outlet of the desulfurizer reactor is tested at the regeneration temperature of 800°C. When the concentration of sulfur dioxide at the inlet and outlet is close, the regeneration is stopped, and the regeneration tail gas is cooled to 70°C in the sulfur recovery device during the regeneration process. Below, the elemental sulfur and the regeneration gas are separated, and a small amount of O is added to the regeneration tail gas 2 / SO 2 After the mixed gas is regenerated, the regeneration rate of the iron oxide-based high-tem...

Embodiment approach 3

[0038] The desulfurized iron oxide high-temperature gas desulfurizer sample obtained in Embodiment 1 is directly regenerated in the desulfurization reactor, at a temperature of 800 ° C, at normal pressure, and prepared by mixing a single gas with 20vol.%O 2 / SO 2 and 80vol.%N 2 The composition of the regeneration gas enters from the bottom of the reactor, where O 2 / SO 2 The volume ratio is 1:100, and the test is at 4000h -1 The sulfur dioxide concentration at the inlet and outlet of the desulfurizer reactor under the regeneration space velocity. When the inlet and outlet sulfur dioxide concentrations are close to each other, the regeneration is stopped. During the regeneration process, the regeneration tail gas is cooled to below 70°C in the sulfur recovery device, and the elemental sulfur and the regeneration gas are separated. At the same time, a small amount of O was added to the regeneration tail gas 2 / SO 2 After the mixed gas is recycled, 4000h -1 The regeneration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com