Helicon wave plasma enhanced chemical vapor deposition unit

A plasma and enhanced chemical technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problems of helical wave plasma mode jumping and other problems, achieve low cost, simple circuit, prevent mode jumping effect of the phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

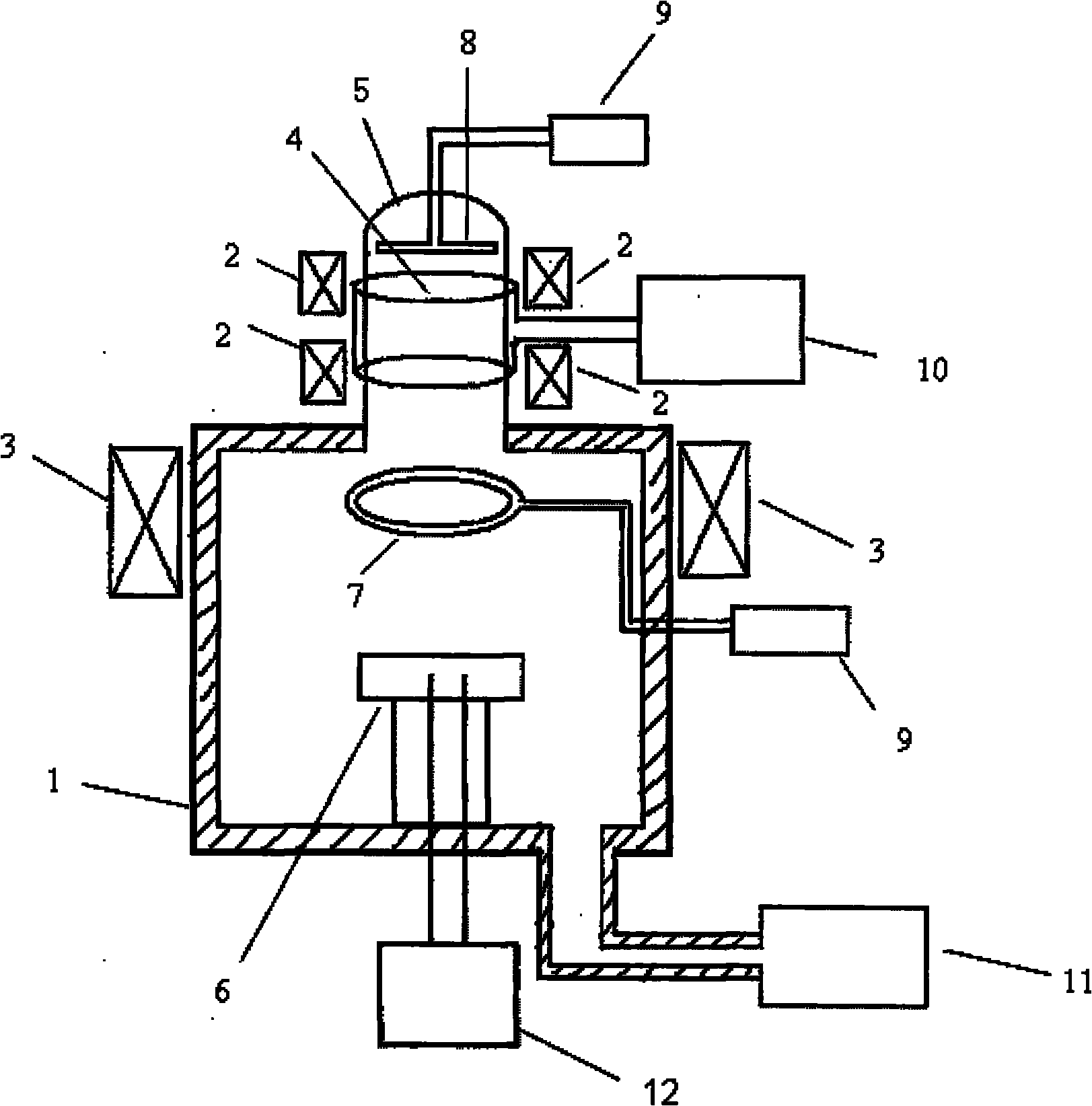

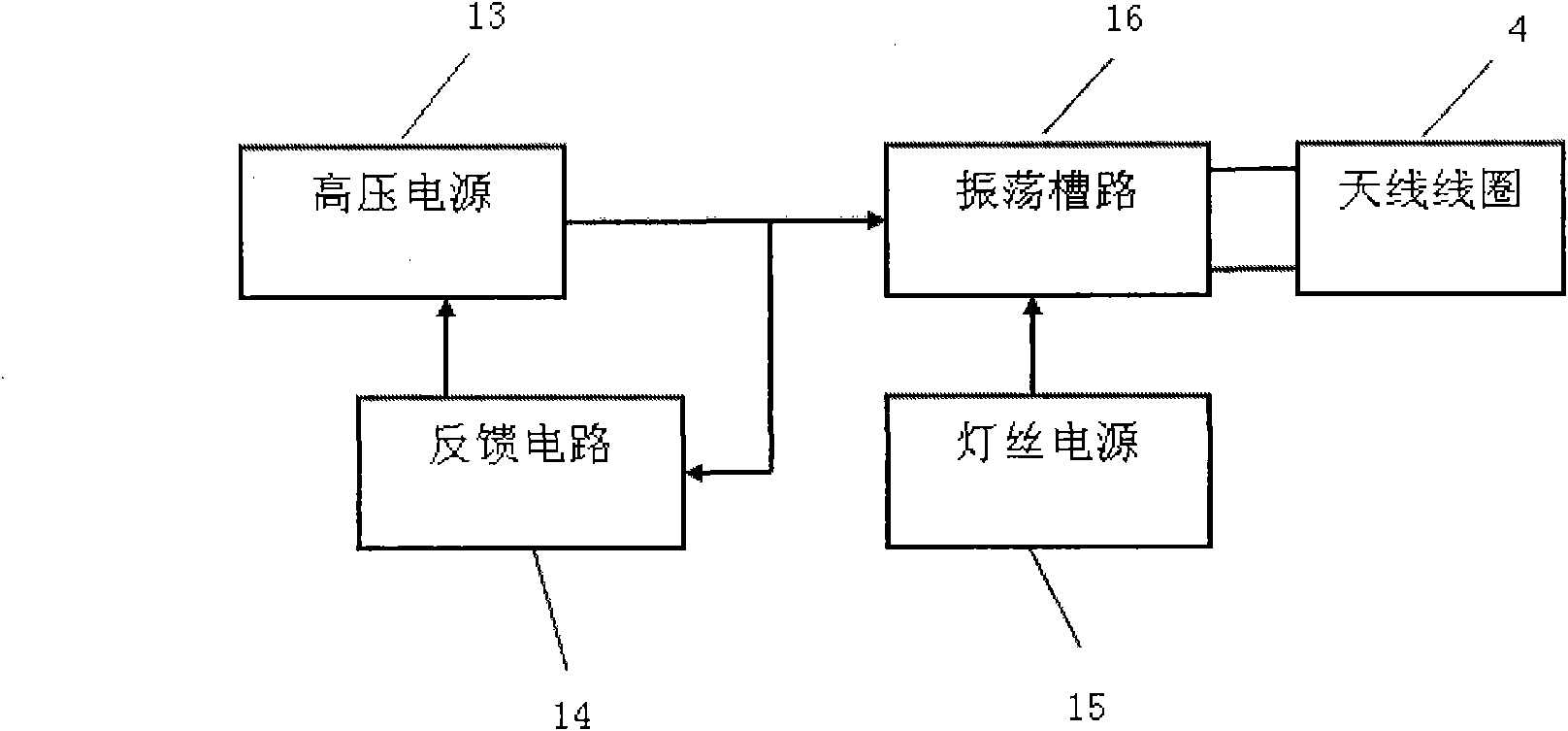

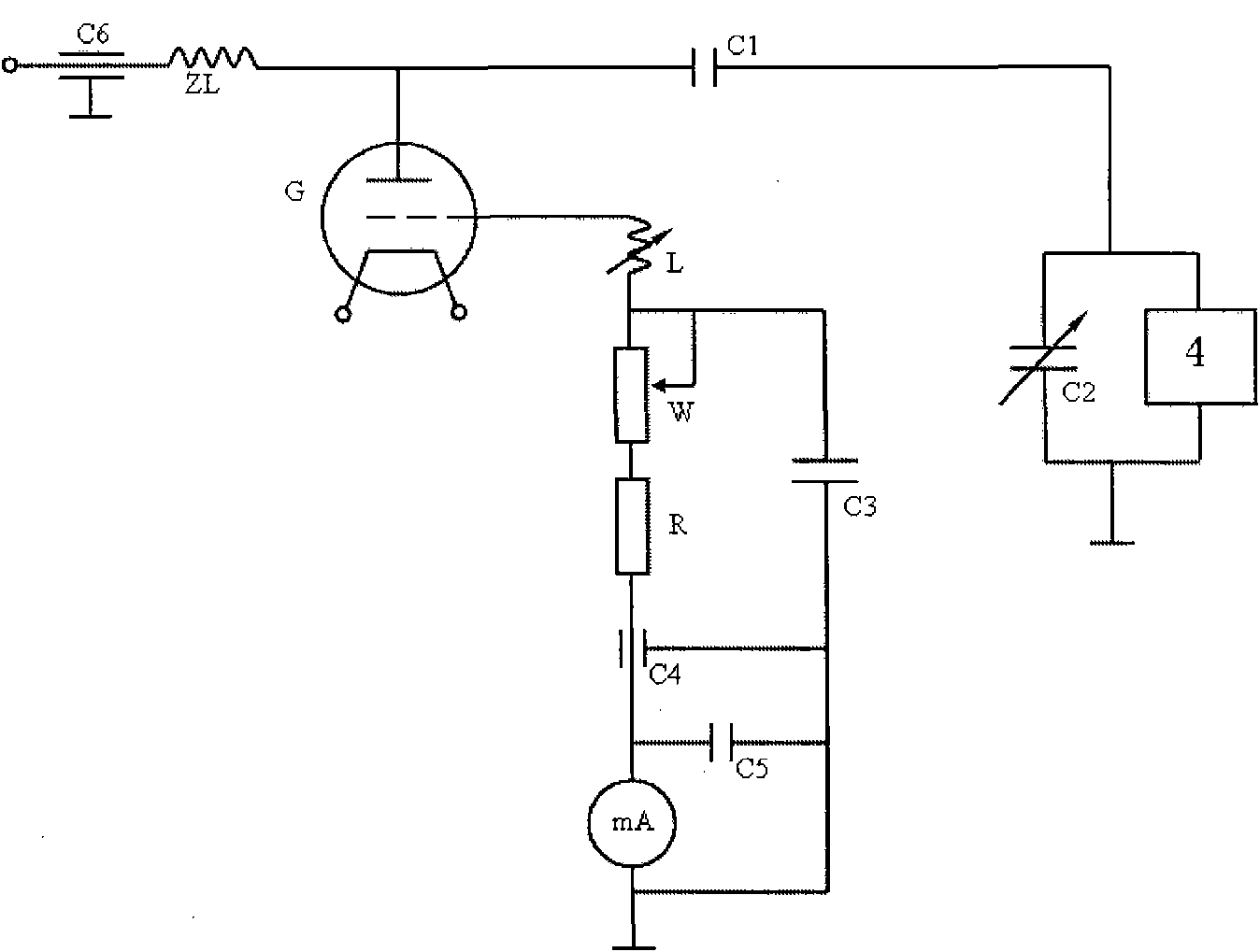

[0013] figure 1 As shown, the present invention is a self-excited helicon-wave plasma enhanced chemical vapor deposition device, which includes a high-voltage power supply 13 for exciting helicon-wave plasma, a self-excited oscillating circuit 10 and an antenna 4, a vacuum system 11, An insulating dielectric tube 5 used as a helicon wave plasma generating chamber and a high vacuum chamber 1 connected thereto as a plasma-enhanced chemical vapor reaction chamber. A coil 2 is arranged outside the insulating dielectric tube 5 to generate an axial magnetic field to meet the conditions for helical wave transmission, and an auxiliary coil 3 for generating a confinement magnetic field is arranged outside the high vacuum cavity 1, and the insulating dielectric tube 5 and the high vacuum cavity 1 are respectively An air inlet 8 and an air inlet control device 9 for feeding reaction gas are provided, and an annular nozzle 7 for feeding reaction gas and a heater 6 for raising the temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com