Cable composite core and manufacturing method thereof

A manufacturing method and composite core technology, applied in cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of high raw material cost, unsatisfactory toughness, large equipment investment, etc., and achieve high thermal deformation temperature and good climate change performance , The effect of small investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

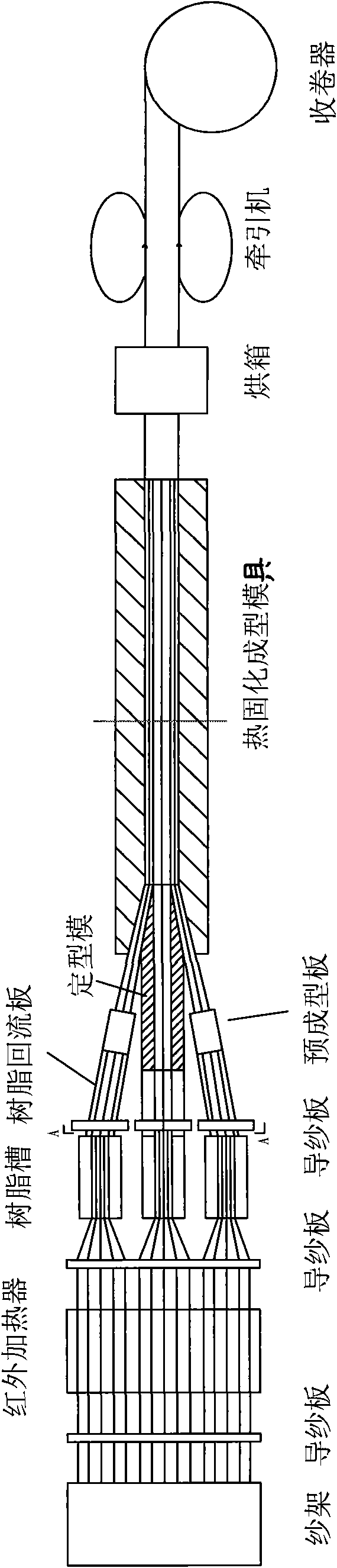

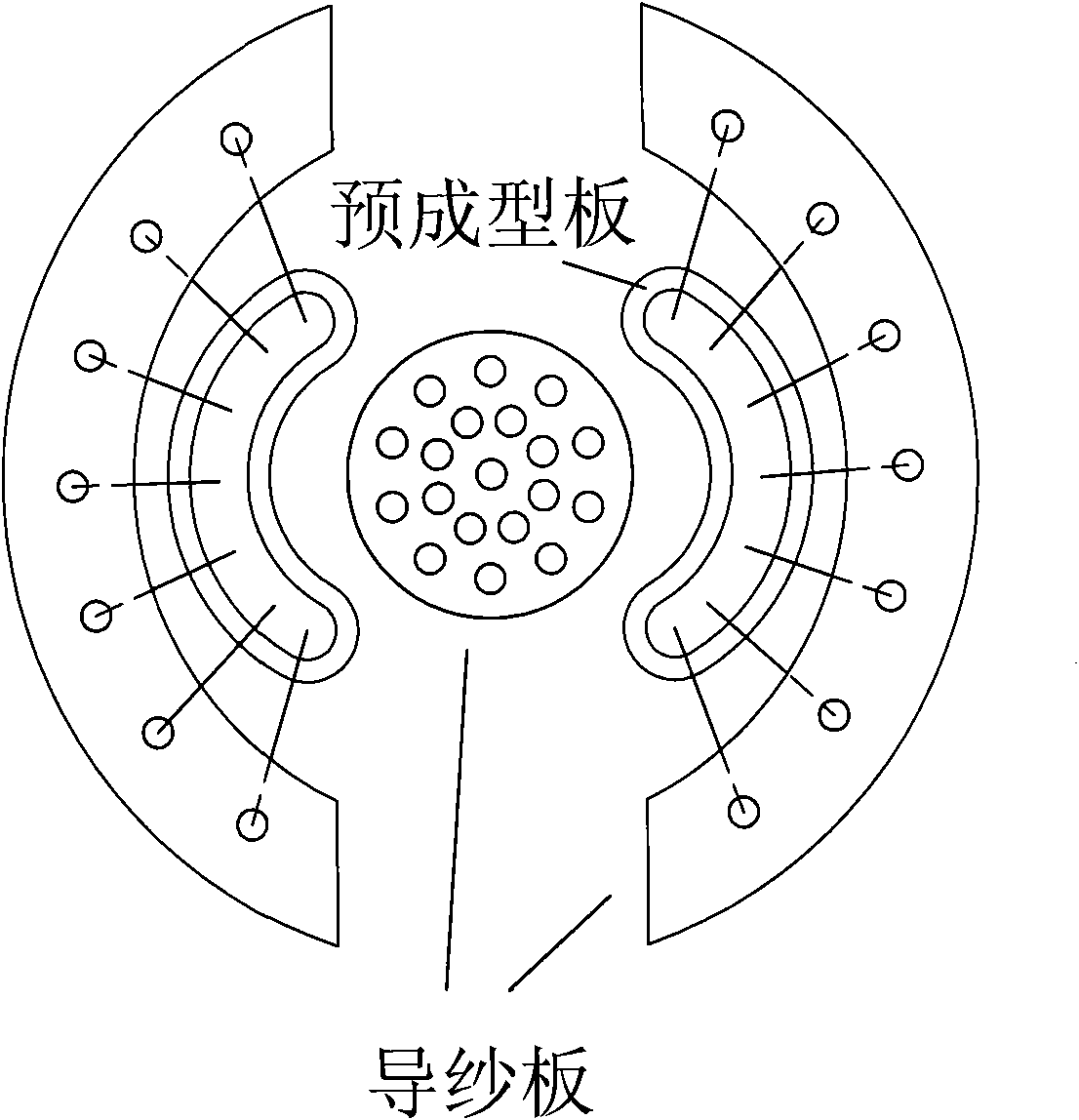

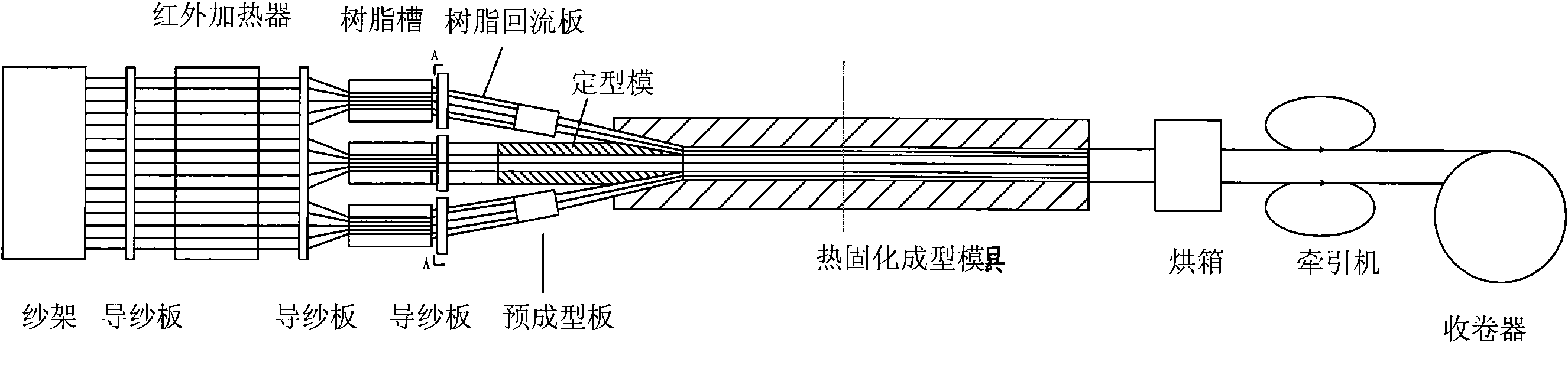

[0019] As shown in the figure, the cable composite core involved in the present invention is composed of inner layer carbon fiber and outer layer glass fiber distributed longitudinally and a mixed resin matrix attached to the inner layer carbon fiber and outer layer glass fiber, according to the total weight of the composite core 56% of carbon fiber, 18% of glass fiber and 26% of mixed resin, said mixed resin is composed of mixture A and accounting for 0.2% phosphorus chloride by weight of mixture A, 0.5% benzyldimethylamine, 1.7% internal mold release Agent INT-1846N, 1.2% simethicone oil, the mixture A is composed of 2.8 parts of bis-resorcinol tetraglycidyl ether (i.e. F-76 epoxy resin) and 1 part of FB resin according to the ratio of parts by weight. 1 part, 1 part of thermoplastic boron phenol resin, 2.8 parts of methyl nadic anhydride, 1 part of 3,3`, 4,4`-benzophenone tetracarboxylic dianhydride, 1 part of chlorobridge anhydride, the FB resin The model number is THC-800...

Embodiment 2

[0021] The cable composite core involved in the present invention is composed of inner layer carbon fiber and outer layer glass fiber distributed longitudinally and a mixed resin matrix attached to the inner layer carbon fiber and outer layer glass fiber. According to the total weight of the composite core, carbon fiber is 66%, glass fiber Fiber 12% and mixed resin 22%, described mixed resin is made of mixture A and accounting for 0.8% phosphorus chloride of mixture A weight, 1.1% benzyldimethylamine, 2.3% internal release agent INT-1846N, 1.8% of simethicone oil is composed, and the mixture A is composed of 3.2 parts of bis-resorcinol tetraglycidyl ether (i.e. F-76 epoxy resin), 1 part of FB resin, thermoplastic boronphenol 1 part of XII resin, 3.2 parts of methyl nadic acid anhydride, 1 part of 3,3`,4,4`-benzophenone tetracarboxylic dianhydride, and 1 part of chlorobridge anhydride. The FB resin model is THC-800 .

Embodiment 3

[0023] The cable composite core involved in the present invention is composed of inner layer carbon fiber and outer layer glass fiber distributed longitudinally, and a mixed resin matrix attached to the inner layer carbon fiber and outer layer glass fiber. According to the total weight of the composite core, carbon fiber is 60%, glass fiber 16% and mixed resin 24%, described mixed resin is made of mixture A and accounts for the phosphorus chloride of mixture A weight 0.5%, the benzyl dimethylamine of 0.9%, the internal release agent INT-1846N of 2.0%, 1.5% % of simethicone, the mixture A is composed of 3 parts of bis-resorcinol tetraglycidyl ether (i.e. F-76 epoxy resin), 1 part of FB resin, thermoplastic boronphenol XII according to the ratio of parts by weight. 1 part of resin, 3 parts of methylnadic anhydride, 1 part of 3,3',4,4'-benzophenone tetracarboxylic dianhydride, and 1 part of chlorobridge anhydride. The FB resin model is THC-800.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com