Method for manufacturing front side grid line electrode of solar battery

A technology of solar cells and front grid lines, which is applied in the manufacture of circuits, electrical components, and final products, and can solve problems such as damage to solar cell substrates, impact on conversion efficiency, and degradation of battery performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

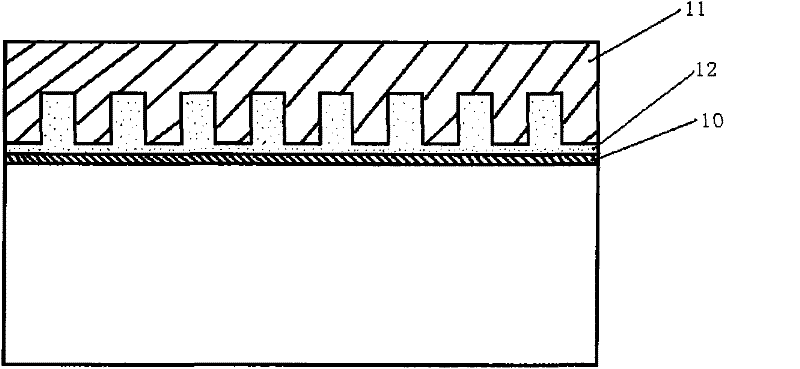

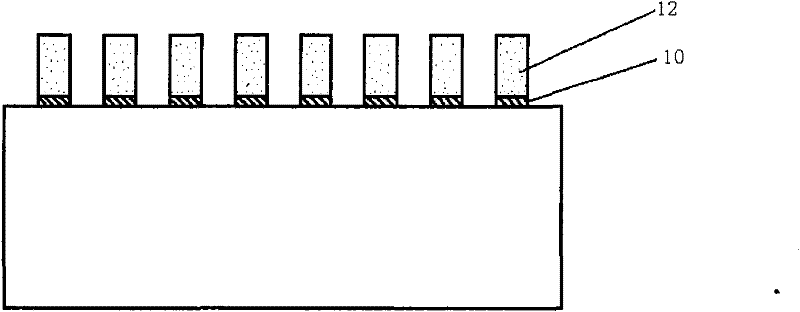

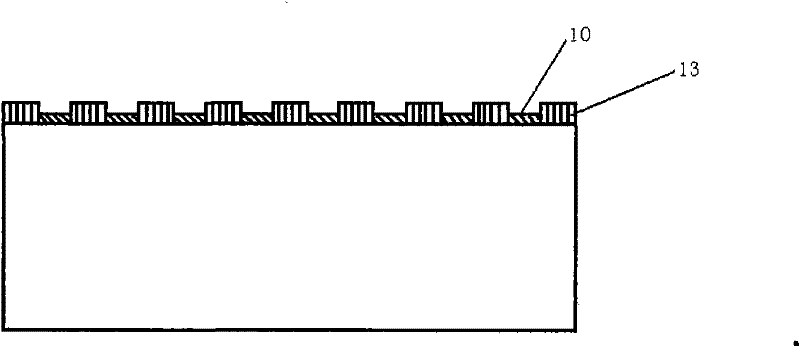

[0016] The sample adopts the solar cell substrate that has completed the PN junction diffusion process and deposited the anti-reflection film 10 . Firstly, the stamper 11 is made, and the corresponding rectangular tooth stamper is designed according to the grid electrode structure on the front of the solar cell. The laser groove method is used to make the rectangular tooth protrusions of the stamper have a width of 80 μm and a height of 100 μm. Coat a layer of diamond carbon film on the mold to avoid adhesion between the stamper and the polymer coating during separation; then spin-coat a plastic film polymer layer 12 with a thickness of 20 μm on the front of the silicon battery; put the battery substrate into the embossing machine And press the stamper on the plastic film and pressurize; remove the stamper to form a corresponding rectangular tooth pattern on the battery substrate; use diluted acetone to etch away the remaining plastic film layer 12 at the groove, and then use h...

Embodiment 2

[0018] The sample adopts the solar cell substrate that has completed the PN junction diffusion process and deposited the anti-reflection film 10 . It is 40 μm that adopting the same method as embodiment one to make protruding width, and height is the rectangular tooth stamper 11 of 50 μm, and on the rectangular tooth stamper, coat a layer of diamond carbon film, avoid adhesion with polymer coating; Spray a plastic film polymer layer 12 with a thickness of 20 μm on the front of the battery; put the battery substrate into the embossing machine and press the stamper on the plastic film to pressurize; remove the stamper to form a corresponding rectangle on the battery substrate Tooth pattern; use diluted acetone to etch away the remaining plastic film layer at the groove, and then use hydrofluoric acid solution to remove the anti-reflection coating to expose the front of the silicon cell; use electroless plating to deposit a nickel seed layer on the groove, and then A layer of 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com