Process for producing heat-expandable base for interior vehicular trim and process for producing base for interior vehicular trim from the same

A thermal expansion, matrix material technology, used in vehicle parts, transportation and packaging, textiles and papermaking, etc., can solve the problems of complicated operation, complicated process, unoptimized cost, scattering, etc., and achieve the effect of light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] Example 1 (Manufacture of Thermally Expandable Base Material for Vehicle Interior)

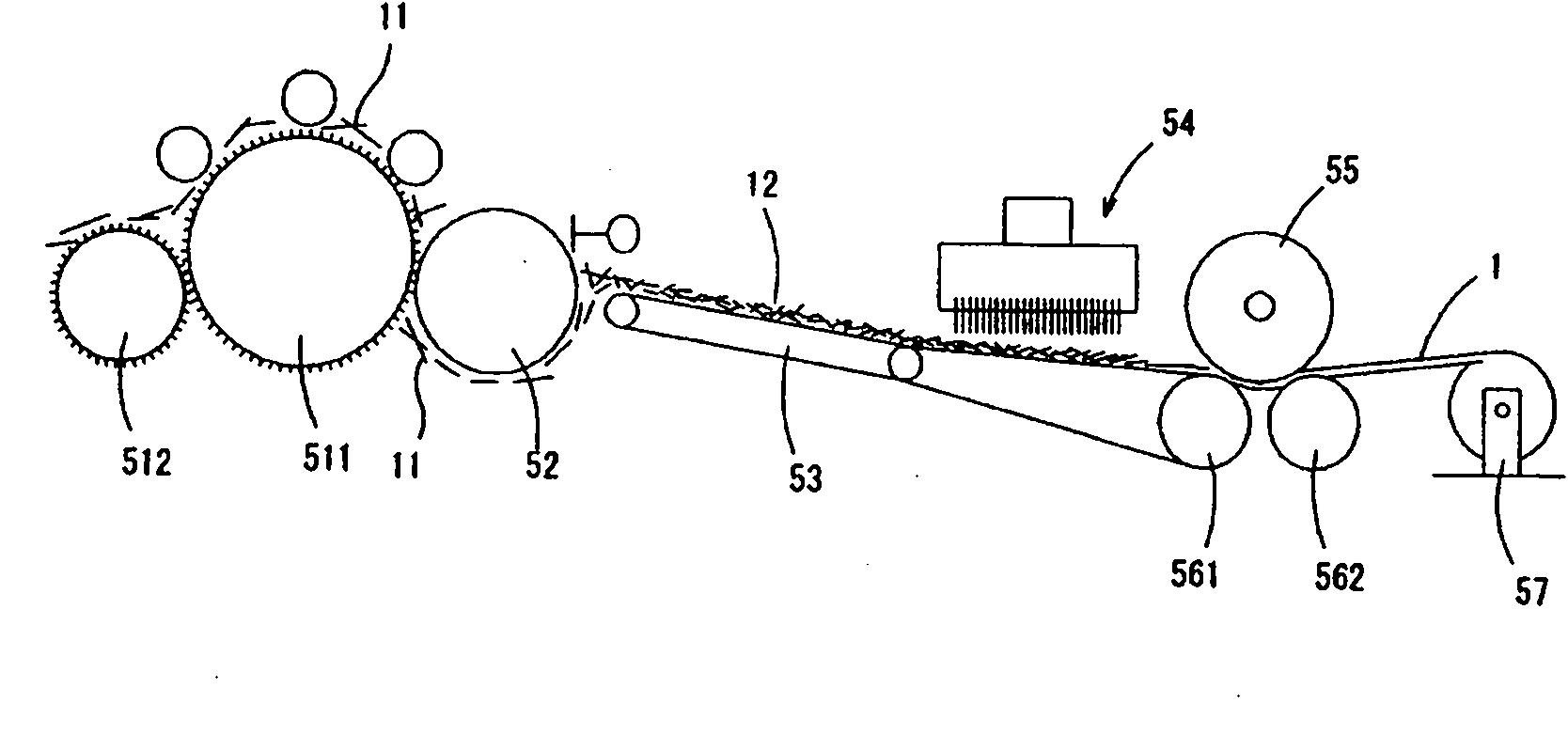

[0072] (1) Production of glass fiber mat (inorganic fiber mat)

[0073] Cut the glass fiber wound into a roving shape into a predetermined length, open it with a fiber opening drum to make a cotton-like glass fiber, place the glass fiber in the air flow, and make it the weight per unit area (fiber density) 280g / m 2 Floating and stacking in the same way to make a glass fiber mat with a thickness of 4.1mm.

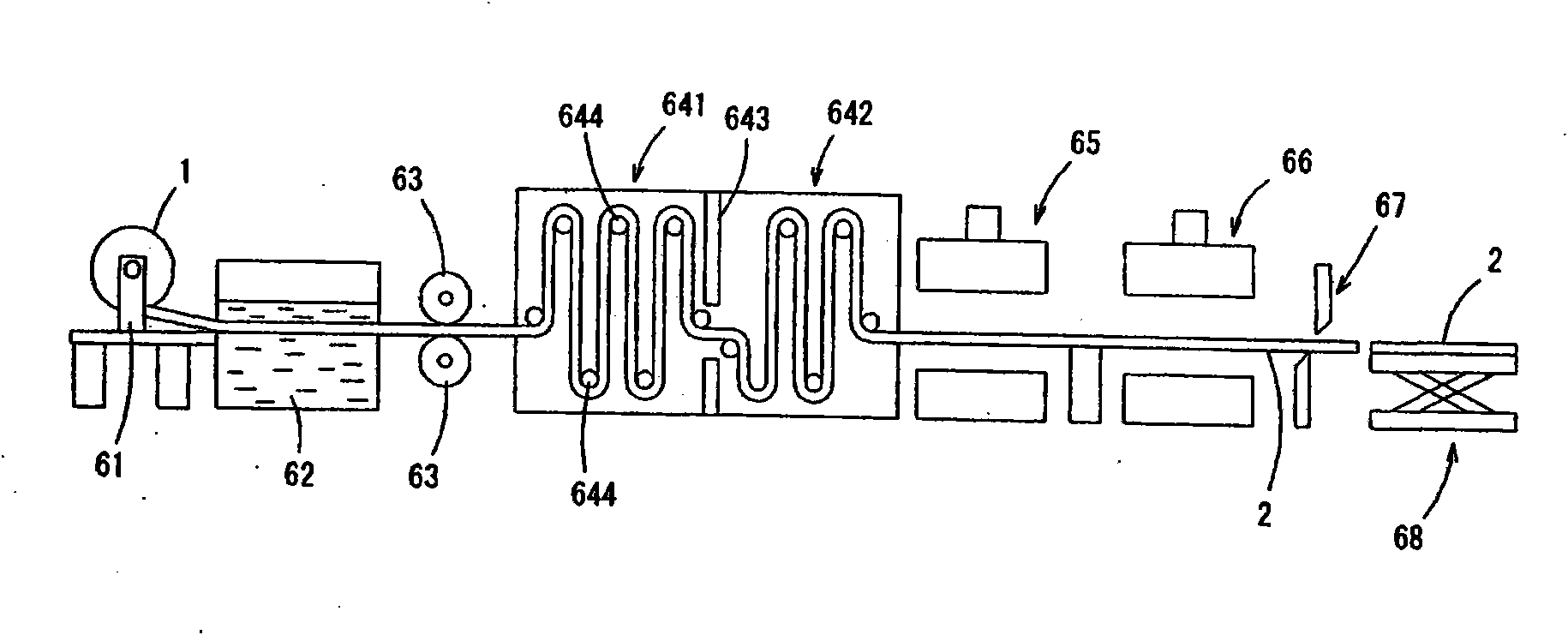

[0074] (2) Preparation of mixed emulsion

[0075] 300 liters of water and 6 liters of surfactant were put into a container with a capacity of 600 liters, and stirred and mixed. Afterwards, 84 liters of dispersions containing 45.7 mass % of high-density polyethylene powder (the fusing point of high-density polyethylene is 147 DEG C) emulsion, 30 liters of dispersions containing 20.5 mass % of heat-expandable microcapsules (thermal expansion start temperature) in this container 178°...

Embodiment 2

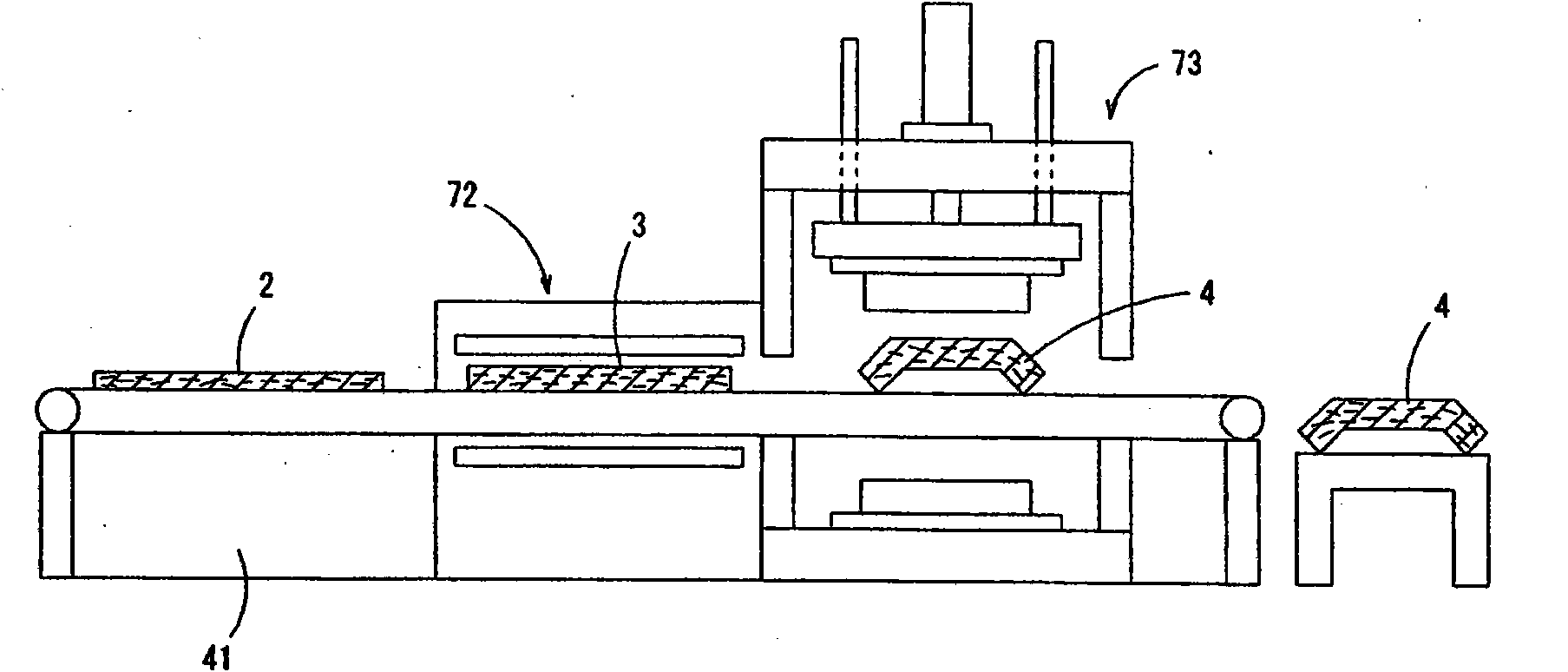

[0078] Example 2 (base material for vehicle interior)

[0079] The thermally expandable base material for vehicle interior produced in Example 1 was left to stand in a heating furnace whose temperature was adjusted to 230° C. for 90 seconds. Thereby, the surface temperature of the heat-expandable base material for vehicle interior became 195° C. (17° C. higher than the thermal expansion start temperature of the heat-expandable microcapsules), and the heat-expandable microcapsules were thermally expanded. Afterwards, the heat-expandable base material for vehicle interior was cooled by a cold press to manufacture a base material for vehicle interior with a thickness of 8 mm. The gap between the cooling plates of the above-mentioned cold press was 8 mm, and water circulated inside the cooling plates, and the cooling plate was cooled. The temperature of the press was set at 18°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com