Epoxy resin composition, cured object obtained therefrom, and light-emitting diode

一种环氧树脂、组合物的技术,应用在电固体器件、电气元件、电路等方向,能够解决增稠倍率高、固化速度快、作业性差等问题,达到增稠倍率低、固化性良好、着色少的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

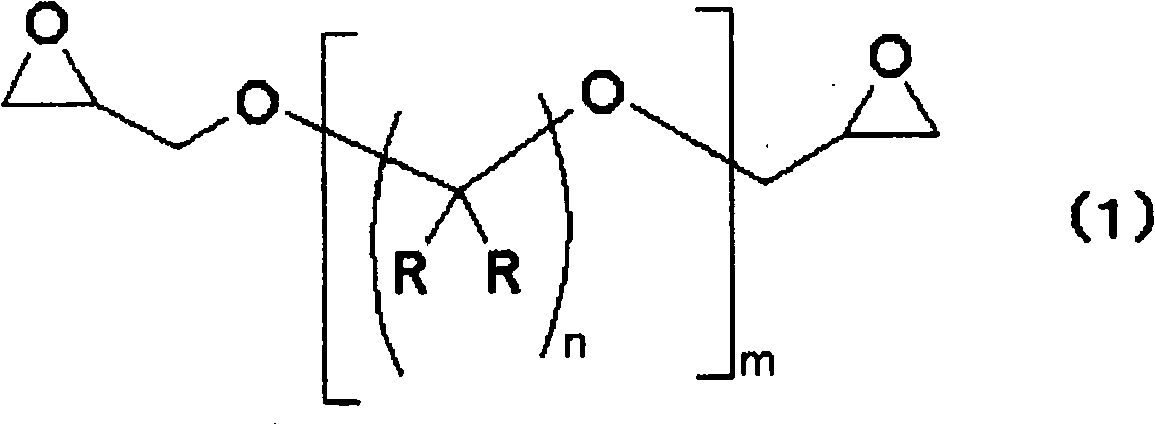

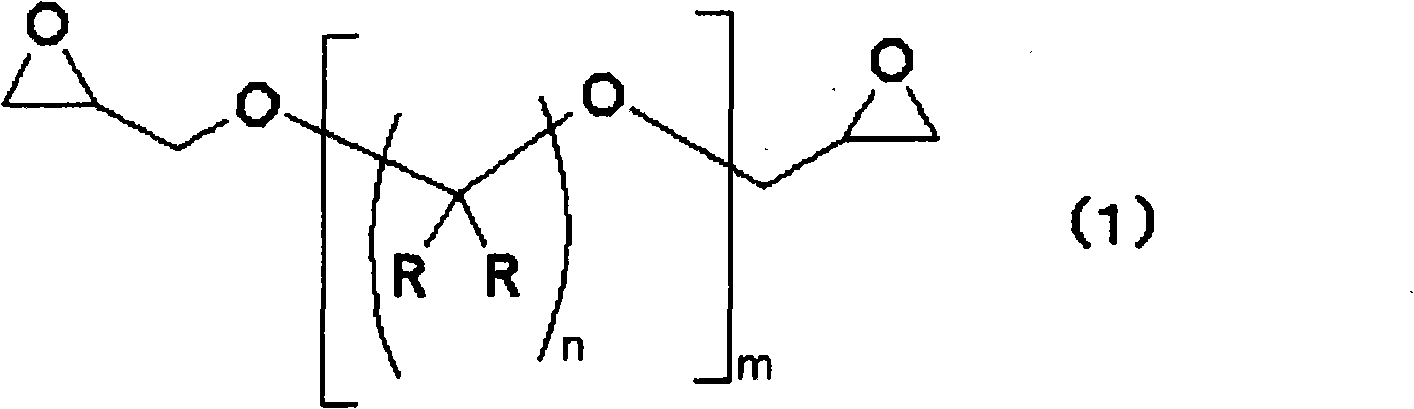

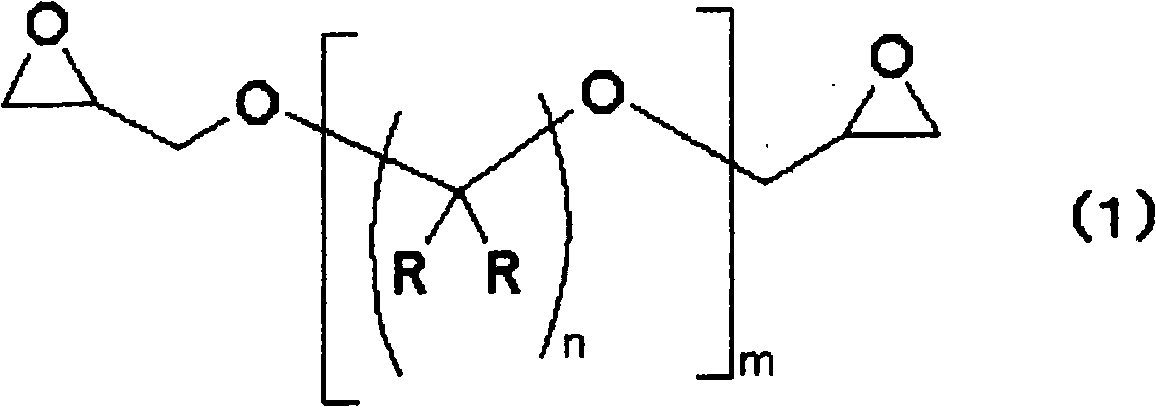

[0113] 79.0 parts by mass of H-TMAn [manufactured by Mitsubishi Gas Chemical Co., Ltd.], 21.0 parts by mass of a mixture of hexahydrophthalic anhydride and methylhexahydrophthalic anhydride [MH700G produced by Shin Nippon Chemical Co., Ltd.], Alicyclic epoxy resin compound [3,4-epoxycyclohexenylmethyl-3',4'-epoxycyclohexene carboxylate, Daicel Chemical Industry Co., Ltd. CEL2021P] 181 parts by mass, 47.8 parts by mass of hexane-1,6-diglycidyl ether [SR-16H manufactured by Sakamoto Pharmaceutical Co., Ltd.] as an epoxy resin compound represented by formula (1), hindered phenolic antioxidant AO-50 ( ADEKA Co., Ltd.) 2.6 parts by mass, the physical property measurement and evaluation of the obtained epoxy resin composition and its hardened|cured material were performed by the said method. The results are shown in Table 1.

Embodiment 2

[0115] Mix 87.0 parts by mass of H-TMAn, a mixture of hexahydrophthalic anhydride and methylhexahydrophthalic anhydride [MH700G manufactured by Shin Nippon Chemical Co., Ltd.] 13.0 parts by mass, alicyclic epoxy resin compound [3 , 4-epoxycyclohexenylmethyl-3', 4'-epoxycyclohexene carboxylate, Daicel Chemical Industry Co., Ltd. product CEL2021P] 150.0 parts by mass, as an epoxy resin represented by formula (1) Compound hexane-1, 48.2 mass parts of 6-diglycidyl ether and 2.4 mass parts of hindered phenolic antioxidant AO-50 (manufactured by Co., Ltd. ADEKA), carry out the epoxy resin composition and its Measurement and evaluation of physical properties of cured products. The results are shown in Table 1.

Embodiment 3

[0117] Mix 52.0 parts by mass of H-TMAn, a mixture of hexahydrophthalic anhydride and methylhexahydrophthalic anhydride [MH700G manufactured by Shin Nippon Chemical Co., Ltd.] 48.0 parts by mass, alicyclic epoxy resin compound [3 , 4-epoxycyclohexenylmethyl-3', 4'-epoxycyclohexene carboxylate, Daicel Chemical Industry Co., Ltd. product CEL2021P] 210 parts by mass, as an epoxy resin represented by formula (1) Compound hexane-1, 28.6 mass parts of 6-diglycidyl ether, hindered phenolic antioxidant AO-50 (manufactured by Co., Ltd. ADEKA) 2.7 mass parts, carry out the epoxy resin composition and its Measurement and evaluation of physical properties of cured products. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com