Microwave method for synthesizing blossom ZnO hierarchical nanostructure

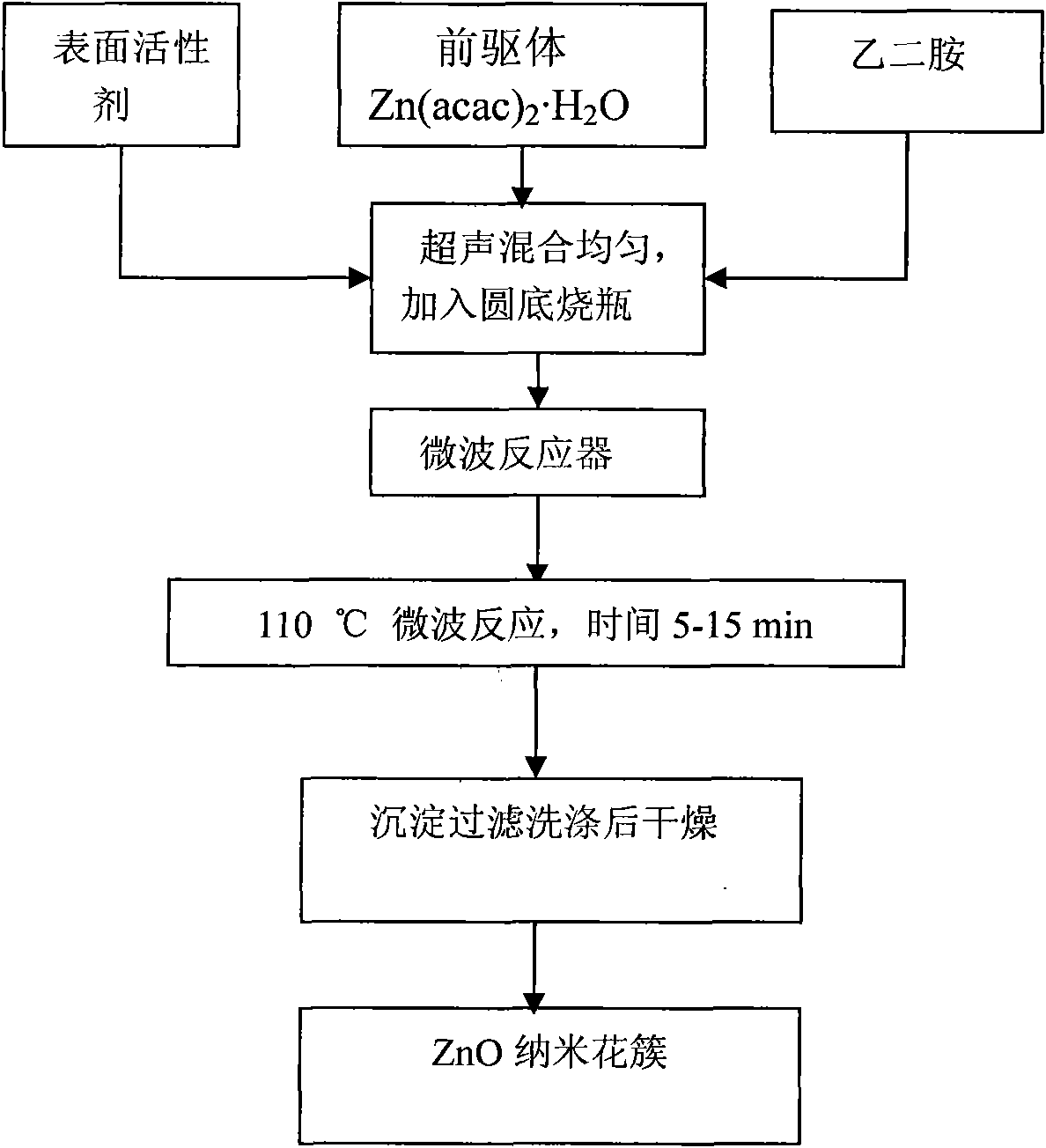

A nano-structure and flower-cluster-like technology, applied in the field of graded nano-structure, can solve the problems of high reaction temperature and long reaction time, and achieve the effects of good repeatability, improved selectivity and easy industrialization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Weigh 0.225g of precursor, add it to 20mL of ethylenediamine, and ultrasonically dissolve it completely to form a precursor solution.

[0030] 2. Transfer the solution to a round-bottomed flask, put it into a microwave reactor, heat and reflux at 110°C for 5 minutes with a heating power of 450W, and then cool to room temperature.

[0031] 3. Use a high-speed centrifuge to centrifuge the mixture in the round bottom flask, remove the upper clear layer, wash the precipitate repeatedly with water, and then wash it with absolute ethanol until the clear liquid is colorless, dry it in an oven, and collect product.

Embodiment 2

[0033] (1)Zn(acac) 2 ·H 2 The synthesis of O precursor is the same as in Example 1

[0034] (2) Preparation of ZnO nanomaterials

[0035] 1. Weigh 0.225g of precursor, add it to 20mL of ethylenediamine, and ultrasonically dissolve it completely to form a precursor solution.

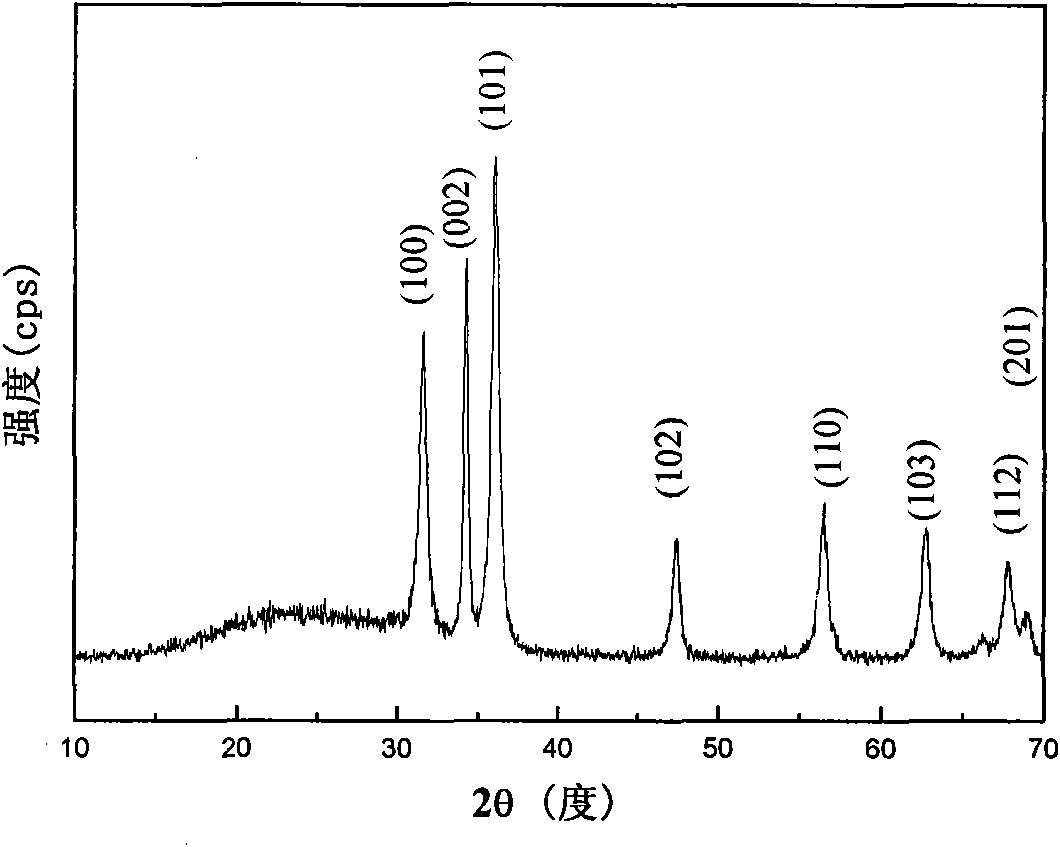

[0036] 2. Transfer the solution to a round bottom flask, put it into a microwave reactor, heat and reflux at 110°C for 10min, with a heating power of 450W, and then cool to room temperature.

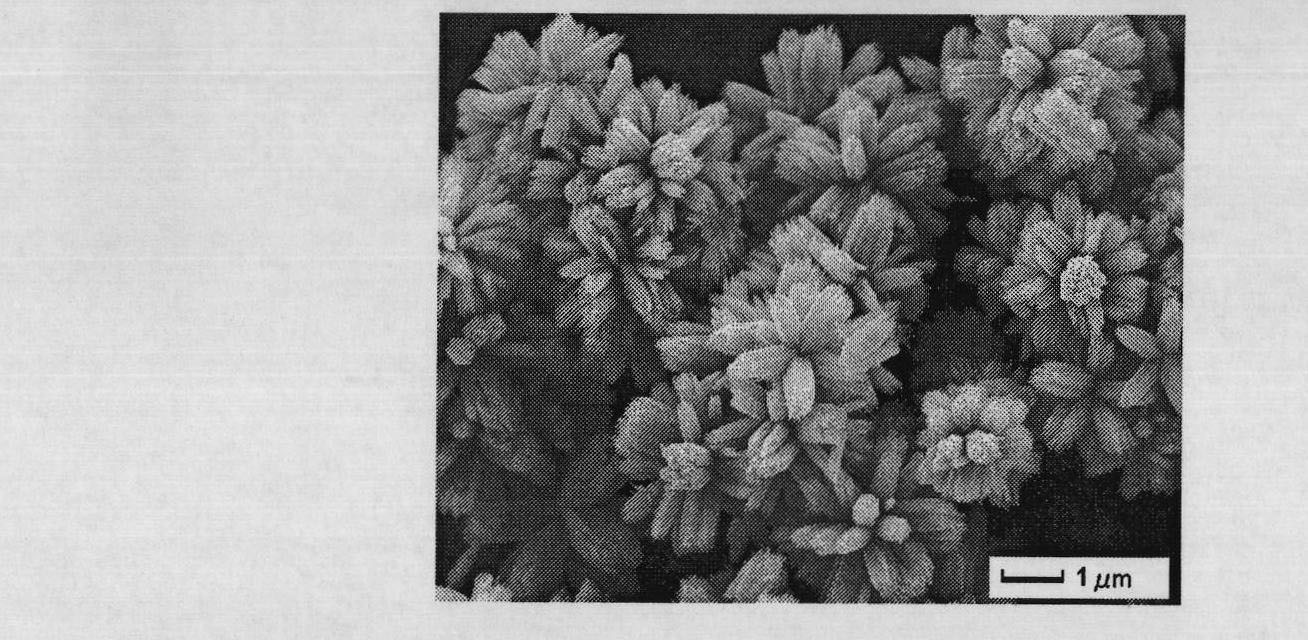

[0037] 3. Use a high-speed centrifuge to centrifuge the mixture in the round bottom flask, remove the upper clear layer, wash the precipitate repeatedly with water, and then wash it with absolute ethanol until the clear liquid is colorless, dry it in an oven, and collect product. The XRD pattern of this experimental example is as follows figure 2 as shown, image 3 As the SEM image of the product, it can be observed that the sample is composed of regular flower cluster structures. Figure 4 The structure of ...

Embodiment 3

[0039] (1)Zn(acac) 2 ·H 2 The synthesis of O precursor is the same as in Example 1

[0040] (2) Preparation of ZnO nanomaterials

[0041] 1. Weigh 0.225g of precursor, add it to 20mL of ethylenediamine, and ultrasonically dissolve it completely to form a precursor solution.

[0042] 2. Transfer the solution to a round-bottomed flask, put it into a microwave reactor, heat and reflux at 110°C for 15 minutes with a heating power of 450W, and then cool to room temperature.

[0043] 3. Use a high-speed centrifuge to centrifuge the mixture in the round bottom flask, remove the upper clear layer, wash the precipitate repeatedly with water, and then wash it with absolute ethanol until the clear liquid is colorless, dry it in an oven, and collect product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com