Silicon-contained type liquid electrolytic degreasing agent

An electrolytic degreasing and liquid technology, applied in the field of degreasing agents, can solve the problems of affecting subsequent processes, difficult to control, and strip steel with milky white tempering color, etc., and achieves the effects of easy control of technical requirements, convenient on-site operation and good use effect.

Inactive Publication Date: 2010-08-25

SHENYANG PARKERIZING

View PDF8 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In the past, electrolytic degreasing was mainly based on powder electrolytic degreasing agent, but powder electrolytic degreasing agent has many disadvantages, such as inconvenient dosing, and a special premixing tank is required for heating and pre-dissolving, while liquid electrolytic degreasing agent is relatively inferior Simple, especially the current new production line is designed according to liquid degreasing agent, there is no premixing tank for powder degreasing agent, and there is no heating device in the storage tank, so powder electrolytic degreasing agent is close to the edge of elimination

In the treatment process, the strip steel is degreased and coated with silicon through the degreasing solution, and silicate is added to the degreasing solution to make the surface of the strip steel adhere to silicon dioxide, which can prevent the strip steel from bonding during annealing, but there are still the following deficiencies: 1. It is not easy to control some technical requirements during electrolysis, such as the amount of silicon coating required to be 1-4mg / m 2 However, the amount of silica attached is not easy to control. If the amount of silica attached is too small, the effect of preventing sintering cannot be achieved; and if the amount of silica attached is too large, the strip steel will easily produce milky white tempering color during annealing, which will affect the appearance of the product. damage and affect subsequent processes

2. The liquid electrolytic degreaser product has stratification and crystallization phenomenon, and it is easy to generate a large amount of foam during electrolysis, which affects the control of technical requirements, and is not convenient for on-site operation

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

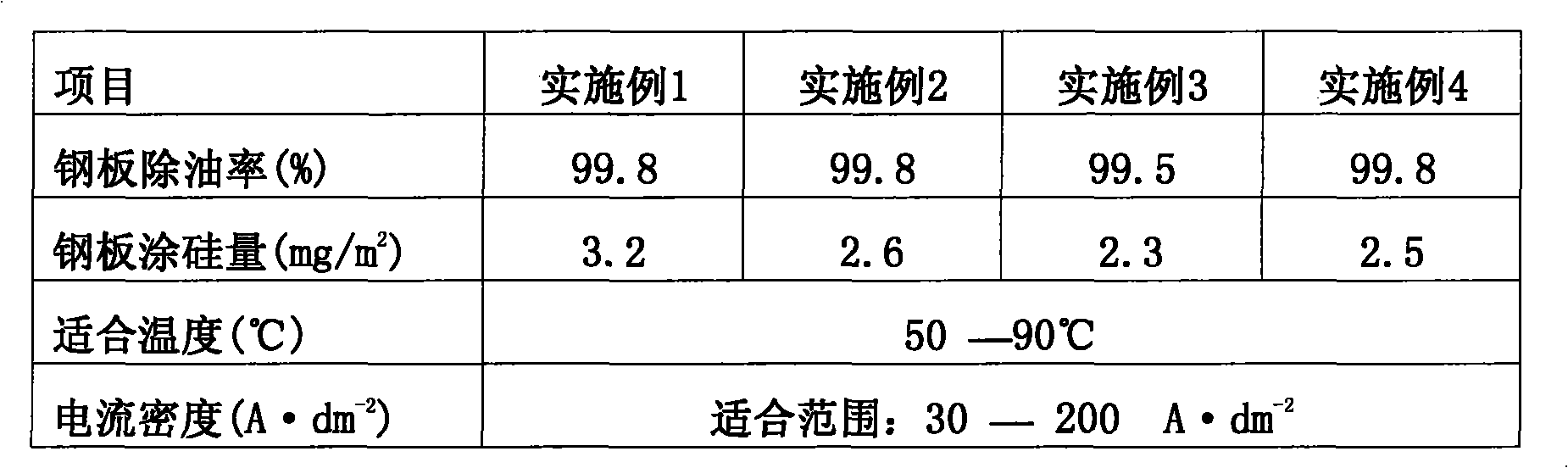

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The relates to a silicon-contained type liquid electrolytic degreasing agent which is characterized by comprising the following materials by weight percent: 20 to 50% of silicate, 20 to 60% of basic salt, 1 to 5% of chelon, 1 to 5% of surface active agent and the balance of water. The silicate is sodium silicate or potassium silicate; the basic salt is sodium hydroxide or potassium hydroxide; the chelon is one or two of sodium gluconate, disodium ethylene diamine tetraacetic acid or tetrasodium ethylene diamine tetraacetic acid; and the surface active agent is complex anionic surfactant NF-25. The invention has the advantages of easy control of technical requirements during use, good use effect, good satiability of liquid electrolytic degreasing agent products, no layering and crystallization phenomenon, strong detergency during electrolysis, few generated bubbles and convenient field operation.

Description

technical field The invention belongs to a degreasing agent used for cleaning strip steel before continuous annealing in a bell furnace, and mainly relates to a liquid electrolytic degreasing agent for degreasing and silicon coating on the surface of a steel plate. Background technique With the rapid development of my country's automobile industry, the quality and production efficiency of cold-rolled steel sheets are increasingly demanding, and the coiled steel strips after cold rolling are prone to bonding during annealing. In order to prevent sticking, in the past, chemical degreasing was used in the process, but at present, electrolytic degreasing is mostly used. The degreasing speed is several times that of chemical degreasing, and the oil removal effect is good. In the past, electrolytic degreasing was mainly based on powder electrolytic degreasing agent, but powder electrolytic degreasing agent has many disadvantages, such as inconvenient dosing, and a special premixin...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C25F1/06

Inventor 杨维毅周宪民黄大勇张建伟

Owner SHENYANG PARKERIZING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com