Gas flow type dynamic liquid phase micro-extraction method

An airflow and dynamic technology, applied in the preparation of test samples, etc., can solve problems such as difficult quantitative analysis, time-consuming, difficult operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

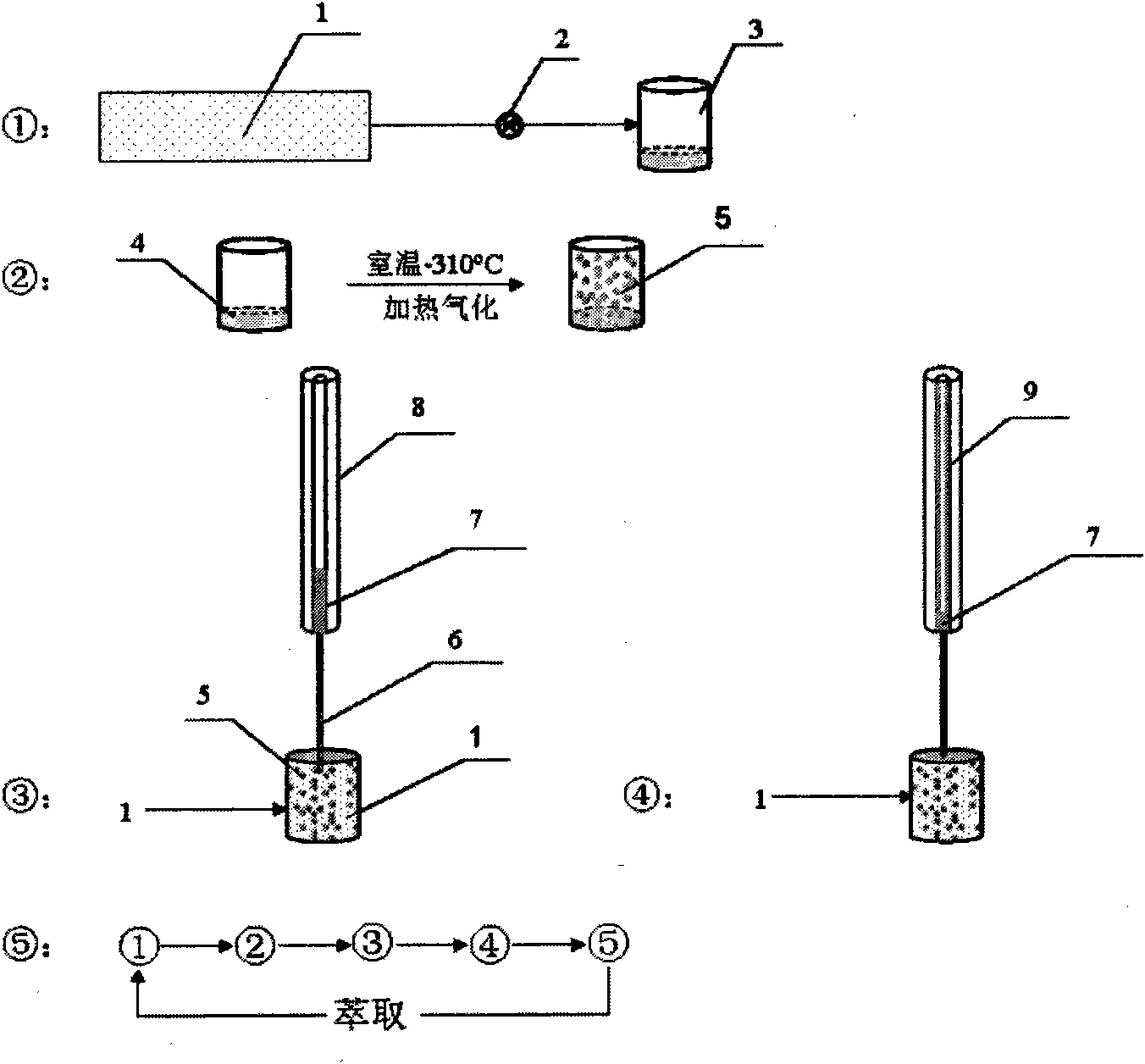

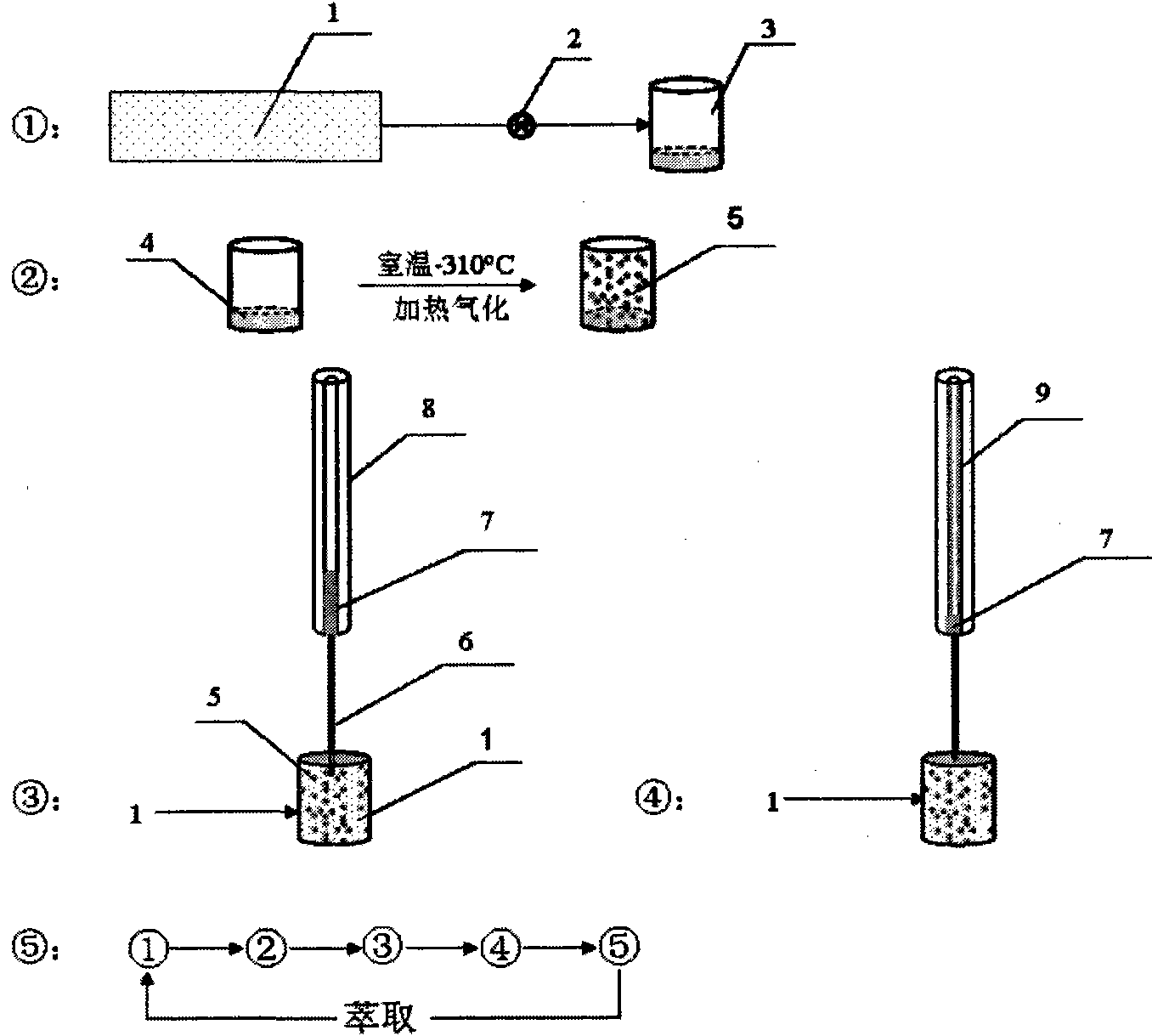

[0016] refer to figure 1 , the specific experimental process is as follows: ①The inert gas 1 is introduced into the sample cell 3 under the control of the mass flow controller 2; ②Under high temperature (room temperature-310°C) heating conditions, the liquid or solid target 4 in the sample matrix evaporates quickly to In the gas phase, a gaseous target object 5 is formed; ③ driven by the inert gas, the gaseous target object 5 reaches the surface of the extraction solvent 7 in the microinjection needle barrel 8 through the microinjection needle 6; ④ when the inert gas passes through the extraction solvent 7, Small bubbles are produced (the bubbles are attached to the extraction solvent 7) and an organic liquid film 9 is formed on the inner wall of the microinjection needle barrel 8, and the gaseous target substance 5 is adsorbed by the extraction solvent 7 and the organic liquid film 9 simultaneously in the process, And the inert gas 1 leaves the extraction system from the micr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com