Processing method for embrittling sausage casing

A processing method and sausage technology, applied in sausage casings, processed meat, slaughtering and other directions, can solve the problems of reducing consumers' desire to buy, not paying enough attention to increasing the crispiness of casings, and affecting the edible function of sausages, so as to improve the desire to buy and increase sales. revenue and competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] The sausage raw material formula is 10kg of lean pork, 1kg of fat, 1.5kg of water, 0.03kg of phosphate, 0.2kg of salt, 0.1kg of glucose, 0.002kg of iso-Vc, and 0.0003kg of nitrous.

[0014] The process is as follows:

[0015] a. Thawing and segmentation: Frozen raw meat is used, and after thawing to a central temperature of -4°C to 0°C, bones, congestion and large fascia are removed to remove impurities.

[0016] b. Grinding meat: Put the divided raw meat in a meat grinder and grind it with an 8mm orifice plate.

[0017] c. Tumbling: Put the minced meat and material water into the tumbler. The total running time is 9 hours, running for 10 minutes, and stopping for 20 minutes.

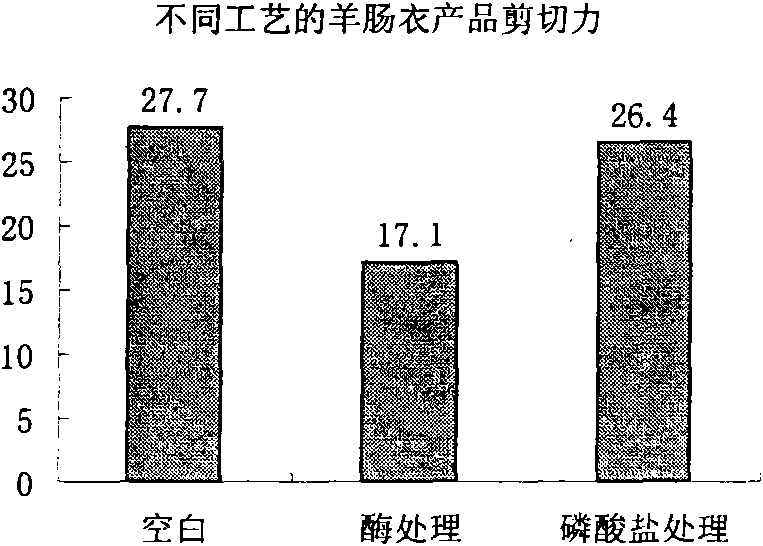

[0018] d. Filling: filling with sheep casings. First soak it in warm water at 35°C for 1 hour, fill it to the required weight, then soak it with 1% papain aqueous solution for 2 hours, and hang it into the smoker.

[0019] e. Fumigation and cooking: The following fumigation and cooking techniq...

Embodiment 2

[0028] The sausage raw material formula is 10kg of lean pork, 1kg of fat, 1.5kg of water, 0.03kg of phosphate, 0.2kg of salt, 0.1kg of glucose, 0.002kg of iso-Vc, and 0.0003kg of nitrous.

[0029] The process is as follows:

[0030] a. Thawing and segmentation: Frozen raw meat is used, and after thawing to a central temperature of -4°C to 0°C, bones, congestion and large fascia are removed to remove impurities.

[0031] b. Grinding meat: Put the divided raw meat in a meat grinder and grind it with an 8mm orifice plate.

[0032] c. Tumbling: Put the minced meat and material water into the tumbler. The total running time is 9 hours, running for 10 minutes, and stopping for 20 minutes.

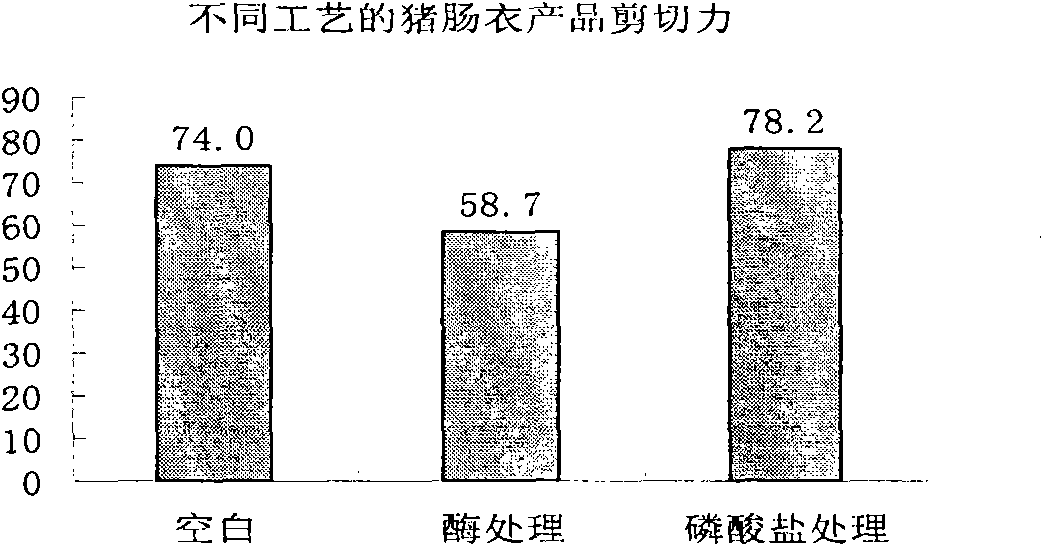

[0033] d. Filling: It is filled with pig casings. First soak in warm water at 40°C for 50 minutes, fill to the required weight, then soak for 3 hours with a 0.8% mass concentration of papain aqueous solution, and hang the rod into a smoker.

[0034] e. Fumigation and cooking: The following fum...

Embodiment 3

[0043] The sausage raw material formula is 10kg of lean pork, 1kg of fat, 1.5kg of water, 0.03kg of phosphate, 0.2kg of salt, 0.1kg of glucose, 0.002kg of iso-Vc, and 0.0003kg of nitrous.

[0044] The process is as follows:

[0045] a. Thawing and segmentation: Frozen raw meat is used, and after thawing to a central temperature of -4°C to 0°C, bones, congestion and large fascia are removed to remove impurities.

[0046] b. Grinding meat: Put the divided raw meat in a meat grinder and grind it with an 8mm orifice plate.

[0047] c. Tumbling: Put the minced meat and material water into the tumbler. The total running time is 9 hours, running for 10 minutes, and stopping for 20 minutes.

[0048] d. Filling: filling with sheep casings. First soak in warm water at 45°C for 40 minutes, fill to the required weight, then soak for 2.5 hours with a 1.2% mass concentration of papain aqueous solution, and hang the rod into a smoker.

[0049] e. Fumigation and cooking: The following fumi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com