Sand core structure for precasting high-pressure oil channel of engine cylinder cover and precasting method

An engine cylinder head, high-pressure oil technology, applied in the directions of casting molds, cores, casting mold components, etc., can solve the problems of increasing the burden of blank foundries and OEMs, reducing labor efficiency, and increasing processing hours, etc. The effect of promoting, improving labor productivity, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

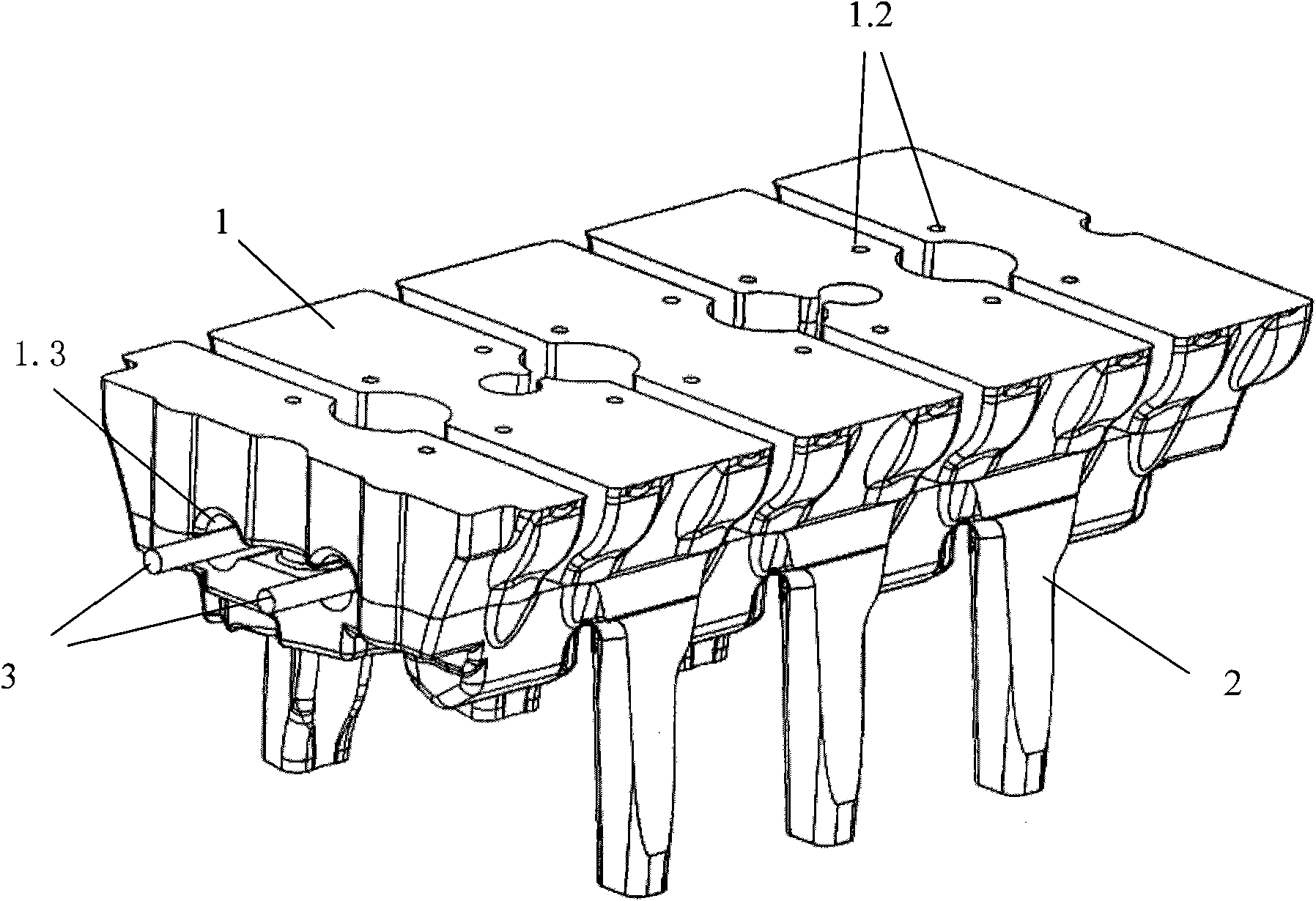

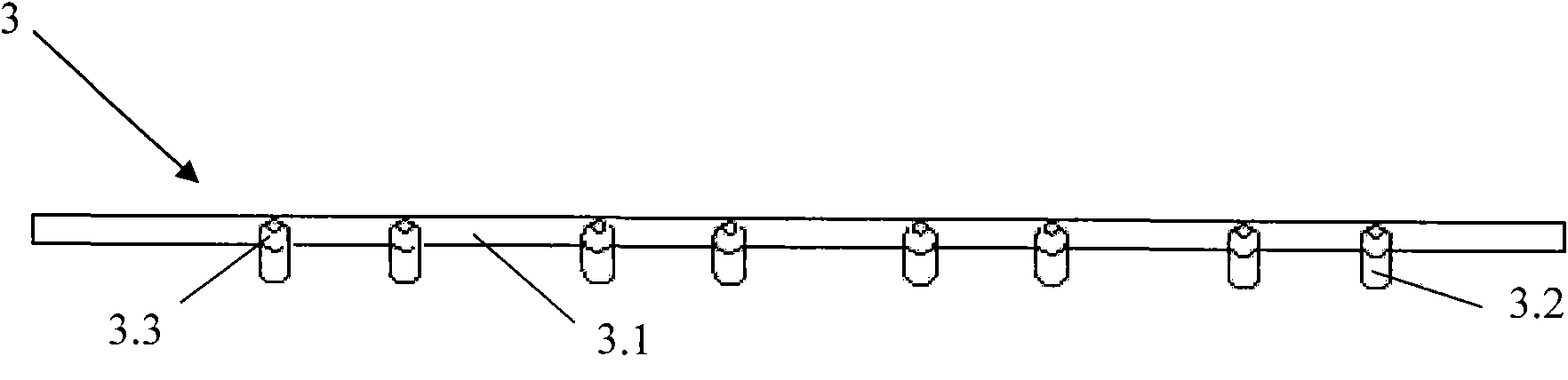

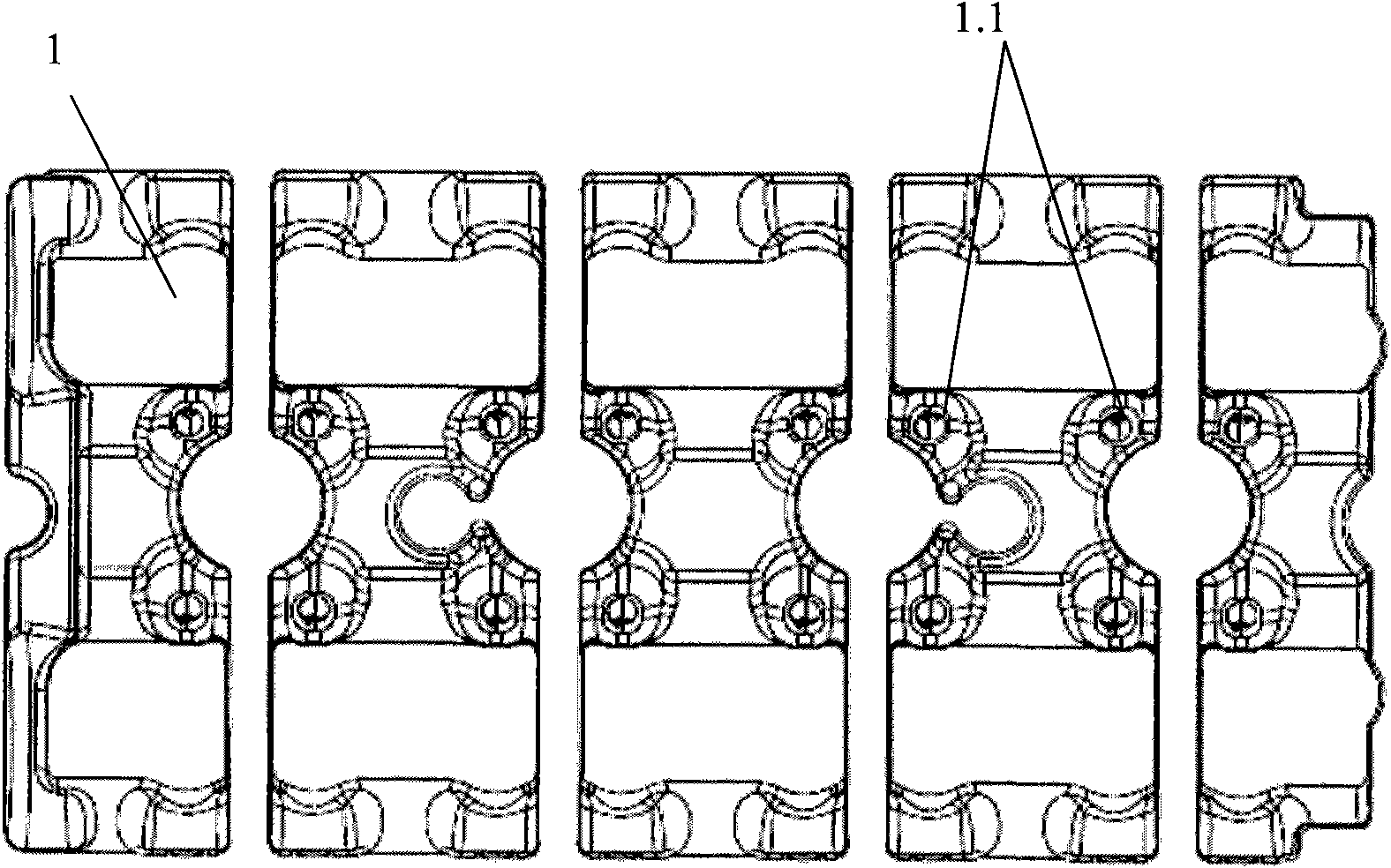

[0033] see figure 1 , the sand core structure used for precasting the high-pressure oil passage of the engine cylinder head, the middle of the lower part of the riser core 1 is correspondingly provided with a through hole 1.3, and the high-pressure oil passage sand core 3 is arranged in the through hole 1.3.

[0034] With the structure of the embodiment of the present invention, after the aluminum alloy cylinder head high-pressure oil passage is pre-cast, the leak test of the oil passage hole can be carried out in the foundry, which can not only strengthen the foundry's ability to control the oil passage leakage rejection rate, but also It can shorten the cycle of rectification of quality problems, thereby reducing the scrap rate in the process of processing. The risk of quality problem claims ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com