Purification method of 7N electronic grade hyperpure ammonia

A purification method and ultra-pure ammonia technology, which are applied in the field of 7N electronic-grade ultra-pure ammonia purification method and purification devices, can solve the problems of increasing the energy consumption of ammonia purification production, device harm, and inability to remove it.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

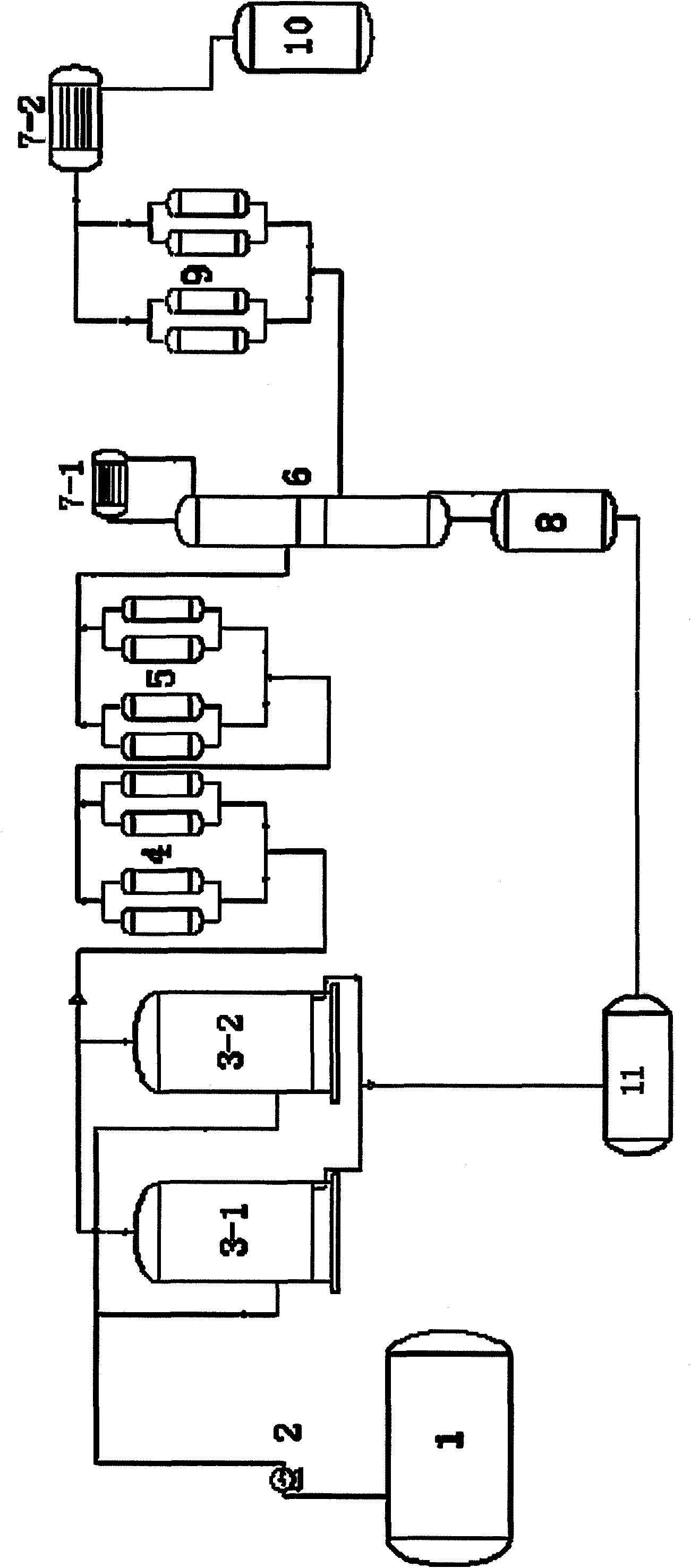

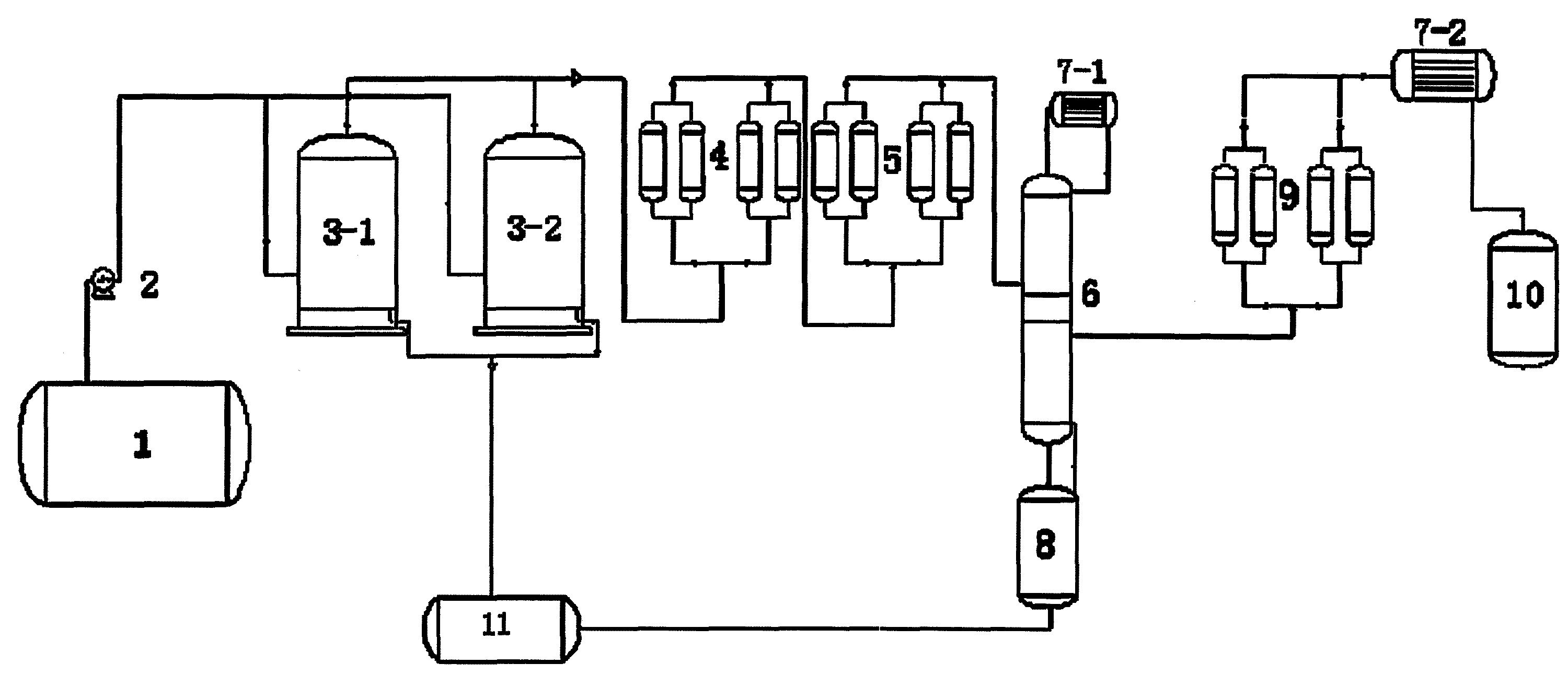

[0021] Hereinafter, the present invention will be described with reference to the drawings.

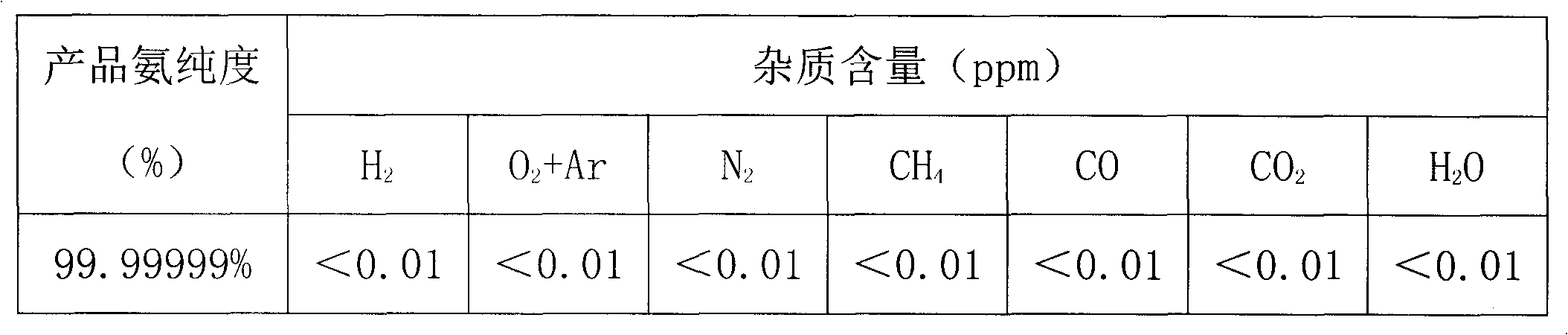

[0022] The purity of raw material industrial liquid ammonia in the present invention is 99.8%, wherein water content2 2 +Ar2 4 3 / h.

[0023] Such as figure 1 As shown, the industrial liquefied ammonia in the storage tank 1 filled with liquefied ammonia is sent into the vaporizer 3-1 or 3-2 through the liquefied ammonia pump 2, and after being vaporized, the oil in the ammonia is removed through the oil remover 4 and the adsorption drier 5 successively. After the water enters the rectification tower 6. During the rectification process, the rising steam in the tower will discharge the low-boiling point H through the condenser 7-1. 2 , O 2 , N 2 、CH 4 Wait for non-condensable gas, the cold capacity of condenser 7-1 and 7-2 is provided by refrigerator. The bottom of the rectification tower is connected to a reboiler 8, which can vaporize the reflux liquid ammonia, and remove high-b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com