Precast composite wallboard with door/window holes and manufacturing method thereof

A technology for door and window openings and composite wall panels, applied to walls, building components, buildings, etc., can solve the problems of unguaranteed construction quality, high construction cost, environmental pollution, etc., to save the decoration period, reduce construction waste, and simplify the construction process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

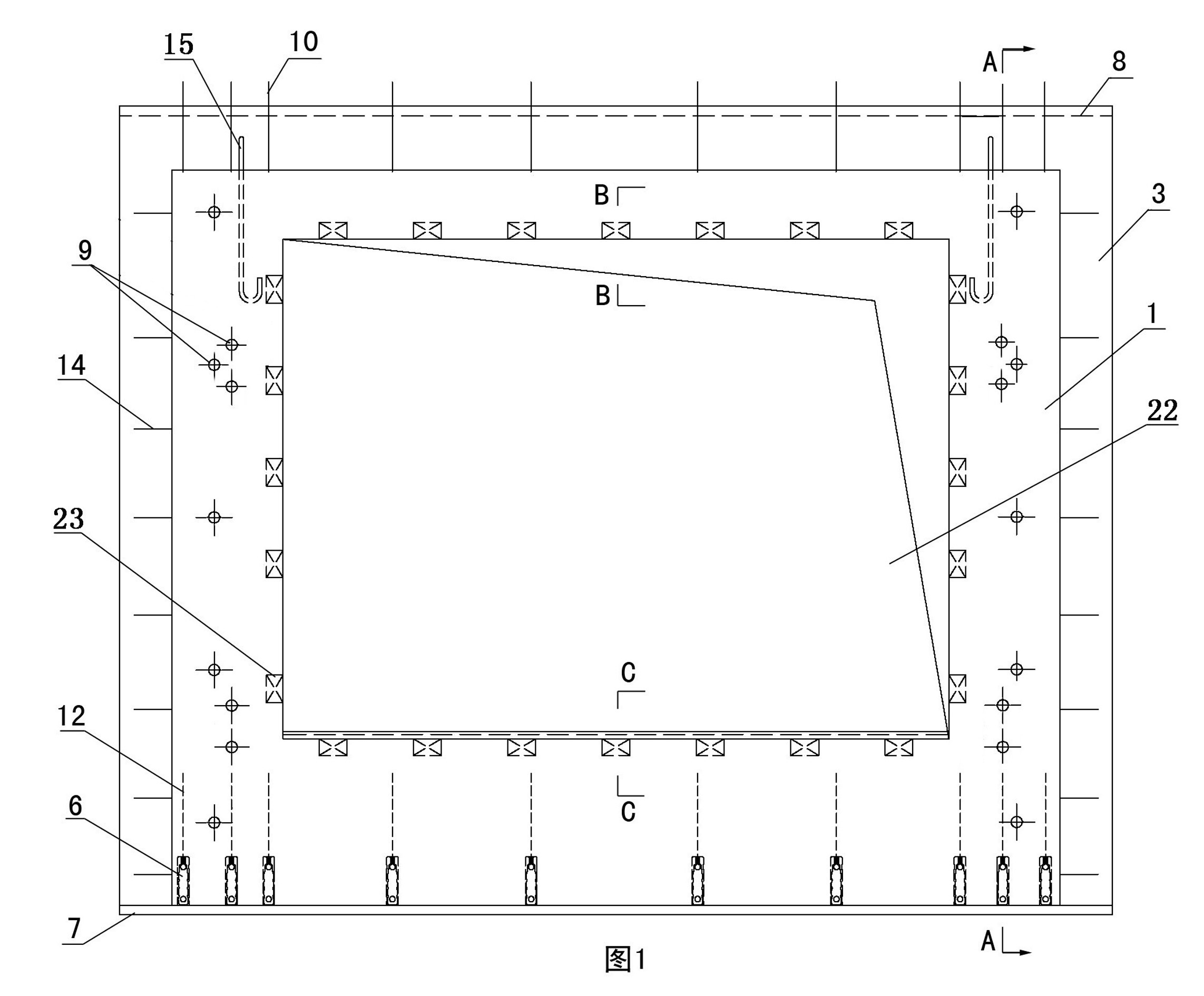

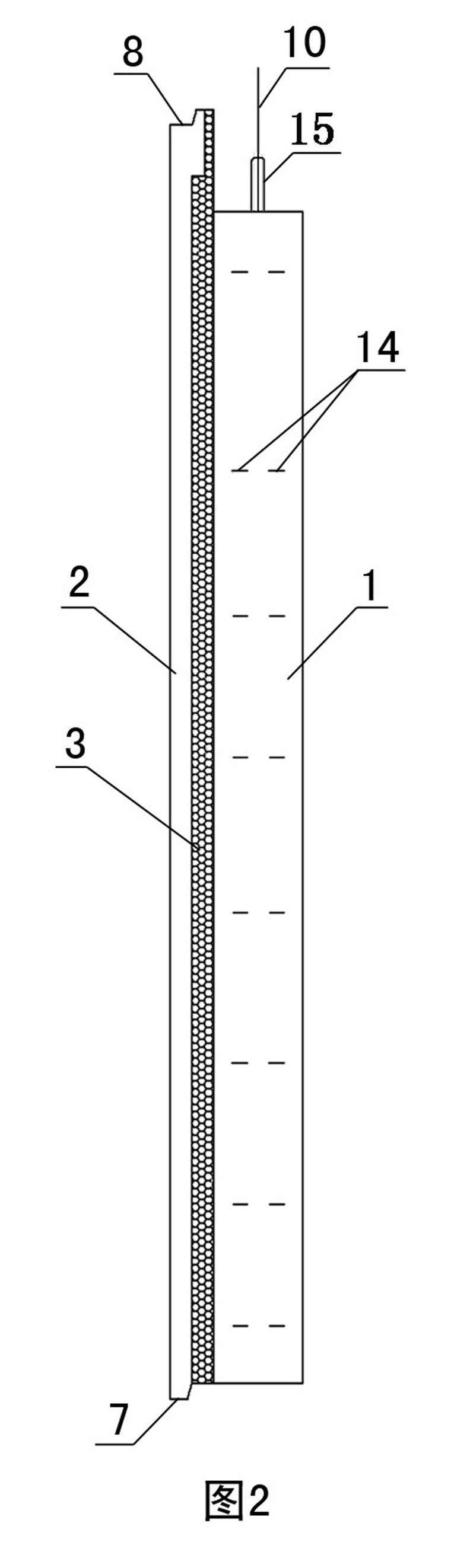

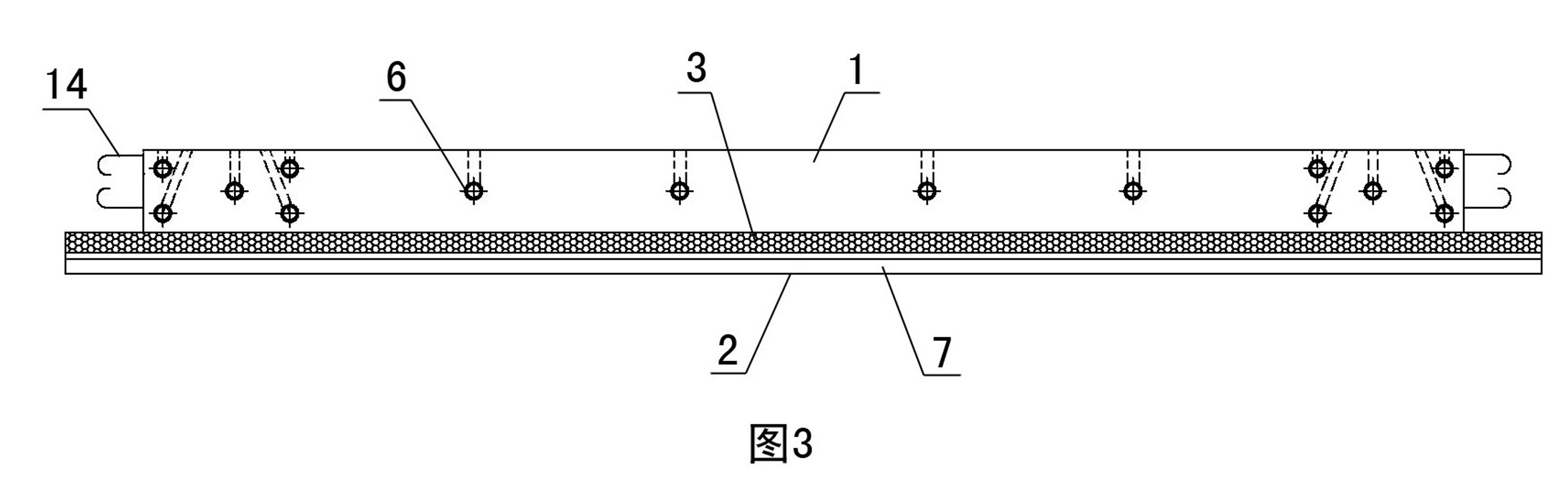

[0073] Embodiment one sees Figure 1-4 , Figure 12 , Figure 13 As shown, this prefabricated composite wall panel with door and window openings has door and window openings 22 (wherein figure 1 The middle is the window opening, Figure 12 The middle is the door opening), and the board body has a structural layer 1, an insulating layer 3 and a protective layer 2 in order from the inside to the outside. There is a steel cage in the structural layer, the insulating layer 3 is extruded polystyrene foam board, and the protective layer 2, there is steel mesh in the concrete, and the structural layer 1, insulation layer 3 and protective layer 2 are interspersed and anchored together by connecting pieces 5 distributed in dots, and the distribution diagram of connecting pieces can be found in Figure 15 . The left and right edges of the protective layer 2 and the thermal insulation layer 3 protrude from the structural layer 1, and the lower edge of the protective layer 2 extends d...

Embodiment 2

[0081] Embodiment two see Figure 5 , the outer surface of the protective layer 2 is connected with an outer decorative layer 4, and the outer decorative layer 4 is a face brick, a paint or a decorative board.

[0082] When the outer side of the protective layer does not need an outer decorative layer, or although an outer decorative layer is required, but the outer decorative layer is not a facing brick, there are two methods for making this prefabricated composite wall panel with door and window openings.

[0083] The first kind: step 1, assembling formwork; Step 2, place reinforcement cage, reinforcement ring 15 and internal thread sleeve 9 on the base form, comprise horizontal tie reinforcement 14, vertical connection reinforcement 10 on the reinforcement cage, reinforce reinforcement sleeve 6 is fixedly connected with the reinforcement cage of the structural layer, and the short grouting pipe 13 and the short grouting pipe 11 are fixedly connected with the steel bar sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com