Method for preparing solid electrolytic capacitor

A technology of solid electrolysis and solid electrolyte layer, applied in solid electrolytic capacitors, electrolytic capacitors, capacitors, etc., can solve the problems of easy oxidation and high price of copper powder, and achieve the effect of overcoming easy oxidation, solving high prices and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

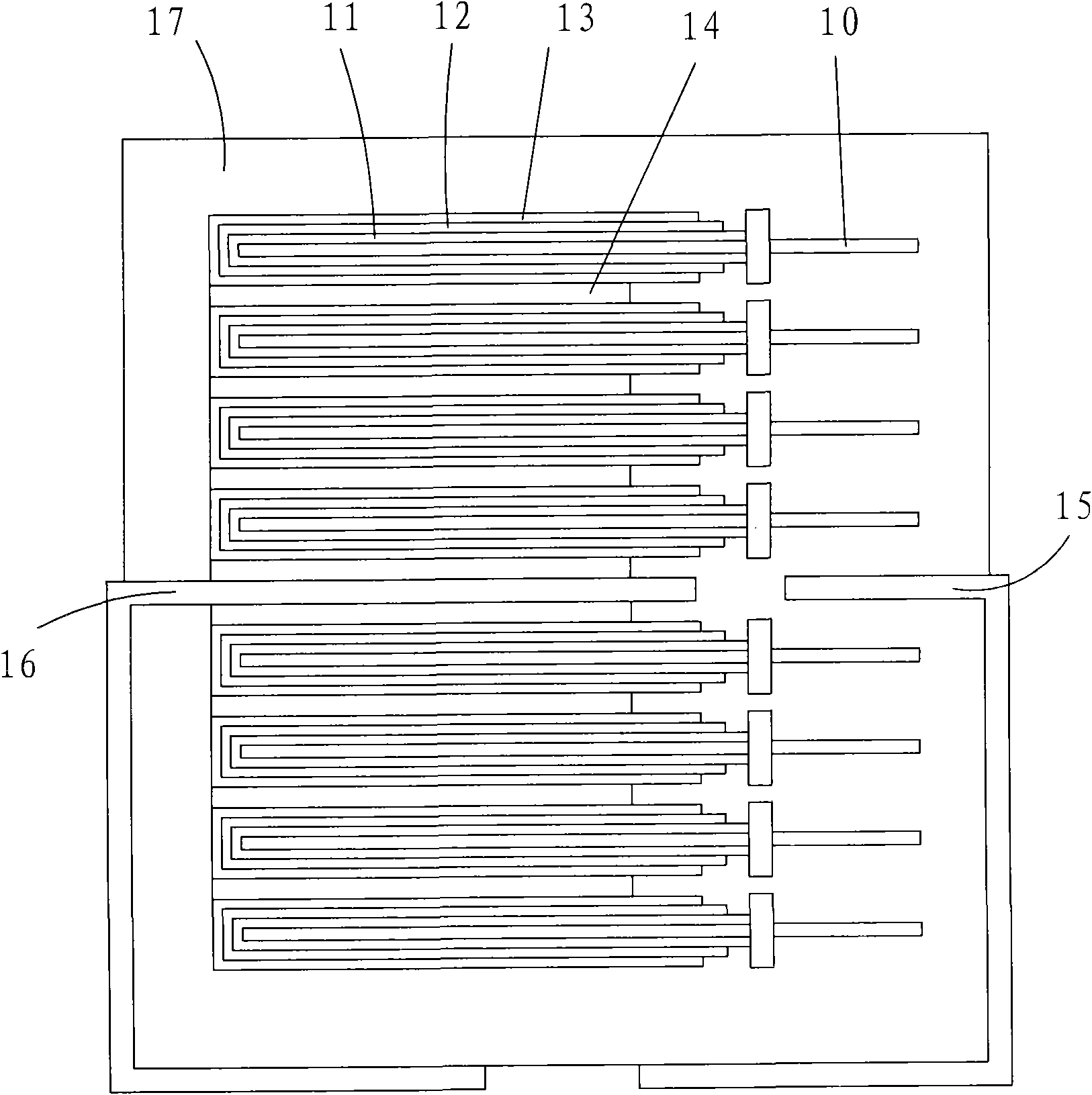

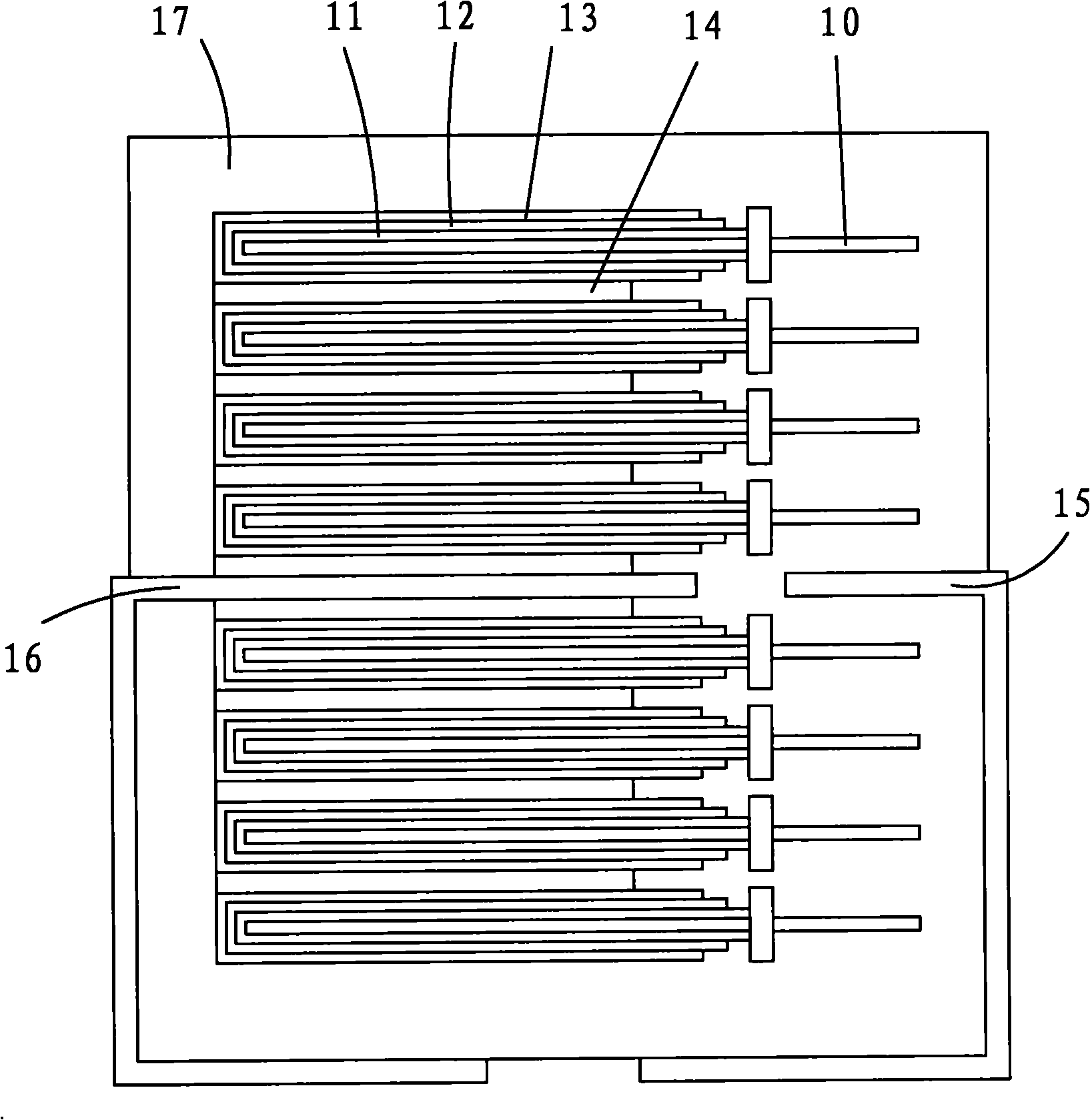

[0016] A method for preparing a solid electrolytic capacitor. A single capacitor element is prepared by sequentially forming an oxide film medium, a solid electrolyte layer, a carbon layer for the first cathode layer, and a silver layer for the second cathode layer on the surface of an anode body. The anodes of a single capacitor element are welded together to make the anode electrode part, and the anode electrode part is then welded on the anode lead frame, and the cathodes of the single capacitor element are bonded together to make the cathode electrode part, and the cathode electrode part is then bonded On the cathode lead frame, it is finally made into a solid electrolytic capacitor by encapsulation with plastic compound; the bonding agent between the cathodes of the single capacitor element and the bonding between the cathode electrode part and the cathode lead frame is silver-clad copper Conductive paste. Silver-coated copper conductive paste is used as the adhesive, whi...

Embodiment 2

[0020] The silver-coated copper conductive paste used in this embodiment has a solid content of 30%, a mass ratio of silver to copper of 3:1, and the rest of the steps are the same as in Example 1.

Embodiment 3

[0022] The silver-coated copper conductive paste used in this embodiment has a solid content of 80%, a mass ratio of silver to copper of 1:50, and the rest of the steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com